The modern world feels fast, digital, and weightless—but beneath every screen, train line, skyscraper, and factory is something brutally physical. Steel.

Before electricity powered cities and before computers reshaped work, humanity hit a wall. Progress was accelerating, but the materials holding civilization together were expensive, fragile, and unreliable. What changed everything wasn’t a new idea about society or politics—it was a breakthrough in metallurgy known as the Bessemer Process.

This single development altered the history of steel production, unlocked mass industrial growth, and reshaped daily life in ways we rarely stop to notice.

The World Before the Bessemer Process

To understand why the Bessemer Process mattered, you first need to picture a world where steel was not a backbone material, but a luxury.

Before the mid-19th century, steel certainly existed, but it was produced in small, controlled batches using methods that had changed little for centuries. Finery forges refined pig iron by repeated heating and hammering, while crucible furnaces melted iron and carbon together in sealed containers. These techniques produced excellent steel, but at a cost that made large-scale use impossible.

In the broader history of steel production, steel was treated almost like a specialty alloy rather than a structural material. It was reserved for applications where nothing else would suffice:

- Blades and weapons that needed sharpness and resilience

- Precision tools used in early manufacturing

- Springs, gears, and mechanical parts requiring elasticity

Everything else relied on cheaper substitutes. Buildings were made of wood, brick, and stone. Bridges and early industrial structures used cast iron, which could bear heavy loads but failed catastrophically when stressed incorrectly. Cast iron’s brittleness meant cracks formed silently—and when they failed, they failed suddenly.

As cities expanded and factories multiplied, these material limits became impossible to ignore. Railways suffered frequent breakages. Machinery wore out faster than it could be replaced. Urban growth stalled because materials simply couldn’t keep up with demand.

Industrial ambition had outgrown medieval metallurgy.

What Was the Bessemer Process and Why Did It Matter?

So, what was the Bessemer process, exactly—and why did it succeed where earlier methods failed?

Developed in the 1850s by British engineer Henry Bessemer, the Bessemer Process was a radical departure from traditional steelmaking. Instead of slowly refining iron through repeated heating and manual labor, Bessemer introduced a method that relied on chemistry and airflow.

Molten pig iron was poured into a large vessel, and air was blown directly through the liquid metal. The oxygen reacted with excess carbon, silicon, and other impurities, burning them off in a controlled but violent reaction. What remained was steel—produced not in hours or days, but in minutes.

The true breakthrough wasn’t just speed. It was predictability.

For the first time in the history of steel production, manufacturers could:

- Produce steel in industrial-scale volumes

- Achieve repeatable, consistent material quality

- Reduce labor costs and human error

- Match steel output to industrial demand

When people ask what was the Bessemer process, the most meaningful answer is this: it turned steel from a scarce resource into a reliable industrial material. That shift unlocked everything that followed.

The Engineering Insight That Changed Everything

Before Bessemer, the idea of forcing air through molten iron sounded reckless. Metallurgists believed oxygen would contaminate the metal and destroy its quality.

Bessemer saw something others missed: oxygen wasn’t the enemy—it was the tool.

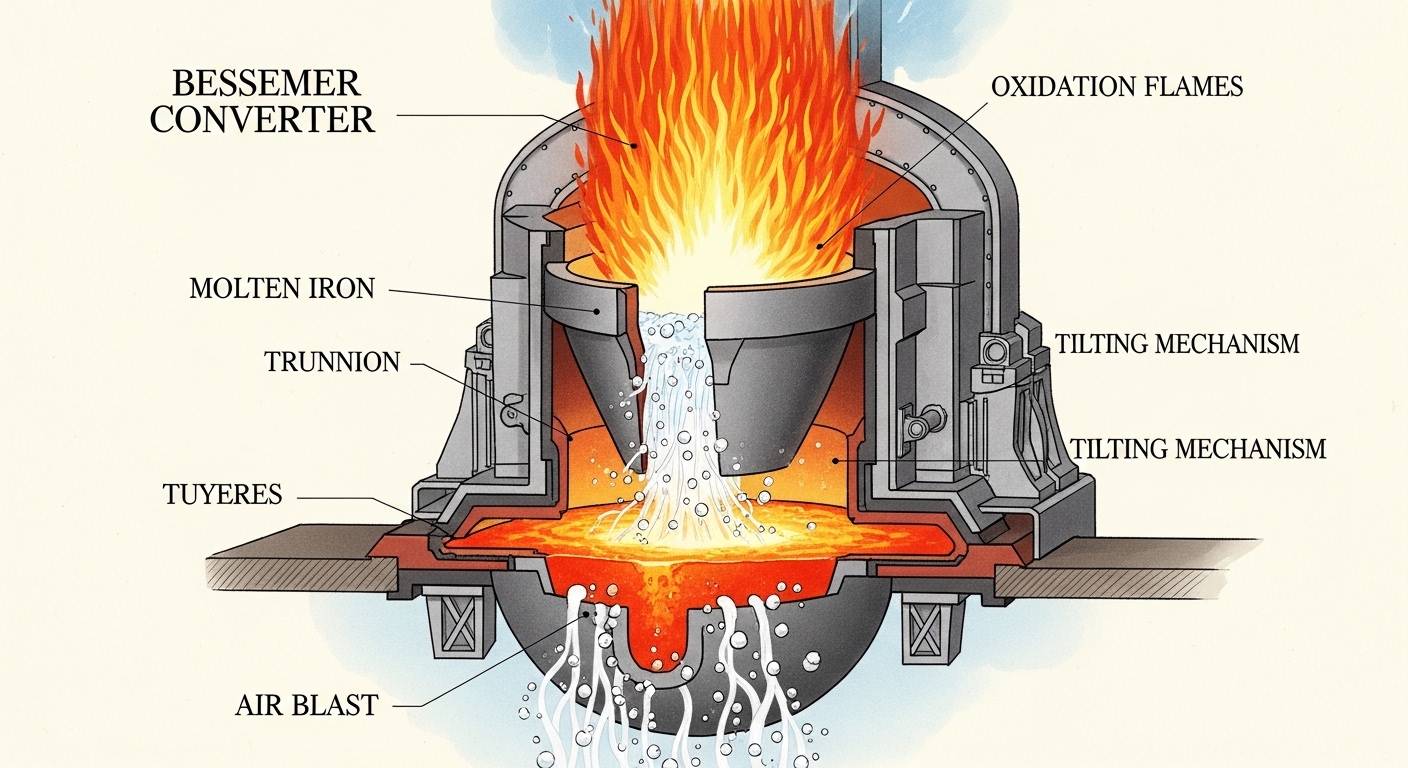

Inside a pear-shaped vessel known as a converter, the process unfolded:

- Molten iron was poured into the converter

- Pressurized air was forced upward through the metal

- Carbon and other impurities oxidized and burned away

- The heat released by oxidation kept the iron molten without external fuel

The brilliance of this design was that the process powered itself. The hotter the reaction became, the more efficiently impurities were removed.

Today, this may sound straightforward. But in the context of 19th-century metallurgy—where craftsmanship and manual control dominated—this was a conceptual leap. Steelmaking was no longer an art practiced by skilled smiths; it became an industrial system governed by chemistry and thermodynamics.

This insight permanently shifted steelmaking from small workshops to large-scale production facilities, redefining how Industrial Revolution inventions approached manufacturing, efficiency, and scale.

The Bessemer Process and the Industrial Revolution

Among all Industrial Revolution inventions, the Bessemer Process stands out not because it replaced others, but because it empowered them.

Steam engines provided power, but they required strong boilers, pistons, and frames. Railways demanded rails that could survive constant stress and vibration. Expanding cities needed materials capable of supporting greater height and weight.

The Bessemer Process arrived precisely when these demands were becoming urgent.

Within a few decades:

- Steel rails replaced iron rails, reducing derailments and maintenance

- Steel machinery allowed factories to operate faster and longer

- Steel tools increased precision while lowering production costs

Each advancement fed into the next. Cheaper steel made better machines. Better machines increased output. Higher output accelerated industrial growth.

In the ecosystem of Industrial Revolution inventions, the Bessemer Process acted as a force multiplier. It didn’t just support progress—it accelerated it, turning industrial ambition into physical reality.

Steel Didn’t Just Change Industry, It Changed People

Most articles describe the Bessemer Process as a breakthrough in engineering. That framing is accurate—but incomplete. What it misses is how deeply steel reshaped everyday human life, not just factories and machines.

This is where how steel changed the modern world becomes impossible to ignore.

When steel became widely available, its impact rippled far beyond industry. Infrastructure stopped being fragile. Transportation became predictable. Buildings became safer. These changes altered how people moved, worked, and lived.

Cheaper, consistent steel led to:

- Safer transportation systems with fewer catastrophic failures

- More durable housing that resisted fire, collapse, and decay

- Faster construction that kept pace with population growth

- Expanded employment across manufacturing, transport, and construction

Reliability was the real revolution. Steel reduced maintenance costs, lowered accident rates, and extended the lifespan of critical infrastructure. Over time, people began to trust large systems—railways, bridges, factories, and urban utilities—because those systems stopped failing unexpectedly.

Understanding how steel changed the modern world means recognizing that social stability depends on material stability. When structures endure, societies can plan, invest, and grow with confidence.

Cities, Skyscrapers, and the Steel Skeleton of Civilization

One of the most visible ways how steel changed the modern world is through architecture and urban design.

Before steel-frame construction, buildings relied on load-bearing walls made of brick or stone. The taller a building became, the thicker its walls had to be—consuming space and limiting height. This made dense cities inefficient and vertical growth impractical.

Steel completely rewrote those constraints.

Steel-frame construction allowed:

- Taller buildings supported by internal skeletons

- Thinner exterior walls that freed up interior space

- Larger windows, better ventilation, and more natural light

- Dense urban centers capable of supporting massive populations

Modern cities are essentially steel frameworks wrapped in concrete, glass, and brick. Elevators, floor plates, and curtain walls all rely on steel’s strength-to-weight ratio.

Those steel skeletons trace directly back to the Bessemer Process, which made structural steel abundant enough to use not just for landmarks, but for ordinary buildings. Without it, the modern skyline simply wouldn’t exist.

Railways, Trade, and the Global Economy

Another often-overlooked dimension of how steel changed the modern world is transportation—and, by extension, global trade.

Early iron rails wore out quickly, cracked under stress, and failed under heavy loads. Steel rails, by contrast:

- Lasted significantly longer

- Carried heavier trains at higher speeds

- Required less frequent replacement and repair

This durability reduced transportation costs dramatically. Goods could travel farther, faster, and more reliably. Markets that were once local became regional, then national, and eventually global.

As rail networks expanded:

- Agricultural goods reached cities cheaply

- Manufactured products reached distant markets

- Supply chains stretched across continents

In this sense, the Bessemer Process laid the physical groundwork for globalization. Long before digital networks connected economies, steel rails and steel ships made global trade practical.

Early Problems and Refinements

The original Bessemer Process was revolutionary—but it wasn’t flawless.

Some iron ores contained high levels of phosphorus, which made the resulting steel brittle. Early failures damaged confidence and slowed adoption, particularly in regions with unsuitable raw materials.

But instead of ending the process, these challenges sparked innovation.

Engineers and metallurgists introduced:

- Controlled reintroduction of carbon to fine-tune steel properties

- Improved chemical analysis of iron ores

- Modified converter linings to handle different impurities

These refinements led to more reliable steel and directly influenced later technologies. Even today, modern steelmaking still relies on oxygen-based refinement. The core principle behind what was the Bessemer process remains embedded in contemporary metallurgy.

It wasn’t a dead-end invention—it was a foundation.

Why the Bessemer Process Is Often Forgotten

Unlike many Industrial Revolution inventions, the Bessemer Process doesn’t have a dramatic, consumer-facing moment.

There’s no switch to flip.

No engine roar.

No personal device to admire.

Steel simply appears—quietly supporting everything.

Because steel is everywhere, it becomes invisible. People notice trains, not rails. Buildings, not frames. Cities, not skeletons.

But invisibility is the hallmark of a truly successful foundational technology. The Bessemer Process worked so well that society stopped noticing the problem it solved.

Steel as Infrastructure, Not Innovation

Great inventions eventually stop feeling like inventions.

The Bessemer Process didn’t just improve steel production—it normalized steel itself. Once steel became ordinary, it faded into the background of daily life.

Yet without it:

- Skyscrapers lose structural integrity

- Railways become unreliable

- Factories slow and degrade

- Cities struggle to sustain scale

In the long arc of the history of steel production, this process marks the shift from scarcity to abundance—from steel as a specialty material to steel as infrastructure.

That transition changed how civilization was built.

Final Reflection: Progress Built on Quiet Breakthroughs

When people ask what was the Bessemer process, they’re usually looking for a technical definition.

But the real answer is far broader.

It was the moment humanity learned how to scale strength—how to produce reliability, durability, and consistency on an industrial level.

Among all Industrial Revolution inventions, few reshaped the physical world so completely, and few continue to influence daily life so silently.

The modern world wasn’t just imagined.

It was forged—one converter at a time.

Continue Exploring the Building Blocks of Progress

If the story of the Bessemer Process made you rethink how materials quietly shape civilization, you might enjoy diving deeper into the inventions and discoveries that laid the groundwork for modern life:

- Invention of Iron and Its Impact – A look at how humanity’s first breakthrough metal transformed tools, warfare, and early societies long before steel entered the picture.

- 5 Accidental Inventions That Changed Everything – Some of the world’s most important innovations weren’t planned at all. This article explores the unexpected mistakes that reshaped history.

- Mechanical Reaper Farming Tool – How one agricultural machine revolutionized food production, labor, and population growth during the Industrial Age.

- Damascus Steel: History, Properties, and Uses – The legendary steel that fascinated warriors and metallurgists for centuries, and why its secrets still intrigue modern science.

Together, these stories reveal a powerful pattern: progress isn’t driven by a single breakthrough, but by a chain of discoveries—each building quietly on the last.