Introduction: What is Damascus Steel?

Damascus Steel is revered for its mesmerizing, wave-like patterns and legendary strength, combining aesthetic beauty with practical utility. Historically, it was known for crafting swords and blades that were not only sharp but incredibly durable. The name “Damascus steel” is derived from either the capital city of Syria or from the word “damas,” which means water in Arabic—symbolic of the flowing, liquid-like patterns on its surface.

The allure of Damascus material lies not only in its intricate appearance but also in the mystery that surrounds it. For centuries, this material has been regarded as a symbol of craftsmanship, strength, and even invincibility. Many stories about Damascus steel blades claim they could cut through rock, other swords, and even the hair of a beard without causing a blemish on the blade. Explore the fascinating history and properties of Damascus steel, and its modern applications in craftsmanship and industry.

History of Damascus Steel

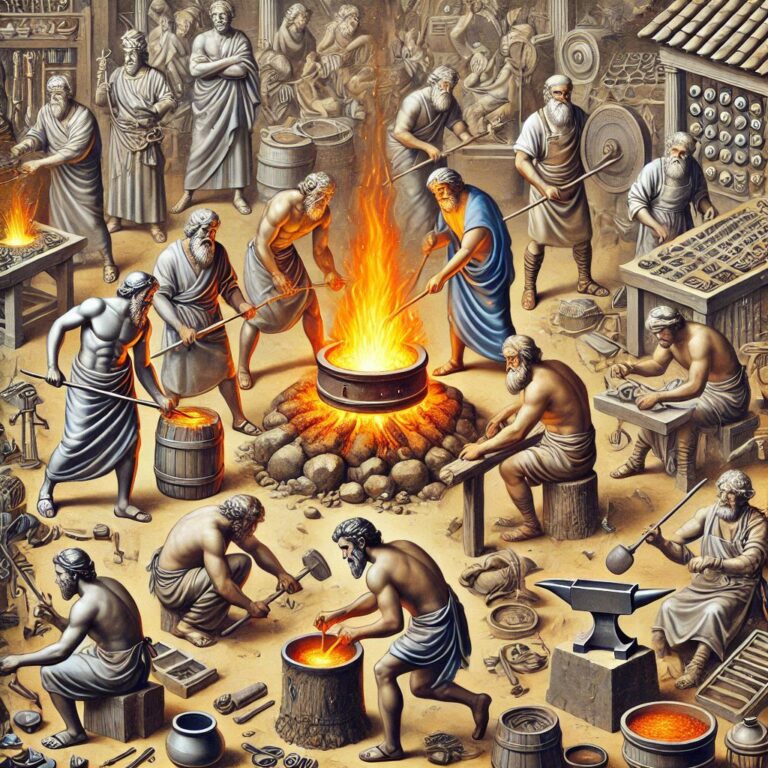

The history of Damascus steel is rich and fascinating, tracing its roots back to ancient India, where it was initially made from a material known as Wootz steel. This high-carbon steel was then traded across the Middle East, with Damascus, Syria serving as a major hub for this highly sought-after metal. The history of Damascus steel is intrinsically linked to these trade routes, as the steel made its way into the hands of master blacksmiths, who used it to forge exceptional blades.

Wootz steel was unique because of its specific metallurgical properties, including the presence of high carbon and the creation of micro-carbide structures during the smelting process. These structures contributed to its legendary strength and its distinctive flowing patterns. The process of creating Wootz steel was so advanced for its time that it became one of the earliest forms of controlled metallurgical engineering.

By the 18th century, however, the original methods of making wootz steel were lost. Historians speculate that changes in trade routes, depletion of essential ores, or the simple loss of generational knowledge contributed to this disappearance. The production process of wootz steel relied on specific types of iron ore found in southern India, which may have become scarce, leading to the gradual decline of true Damascus manufacturing.

Despite various attempts by modern metallurgists to recreate the ancient techniques, the exact methods remain elusive. The mystery surrounding the history of Damascus steel adds to the intrigue of this ancient material and keeps metallurgists and historians captivated. Although modern blacksmiths have managed to produce similar-looking steels, true Damascus steel properties remain difficult to replicate with complete accuracy.

Damascus Steel vs. Pattern-Welded Steel

In modern times, many products labeled as “Damascus steel” are not truly the same material as their ancient counterpart. Instead, they are pattern-welded steel, a technique involving layering and forging different types of steel together to create the signature wavy pattern. While these modern blades look similar to ancient Damascus material, they do not possess the same metallurgical properties as Wootz steel.

Pattern-welded steel is created by folding layers of iron and steel together, and then hammering them at high heat to bond the materials. This process creates a blade with contrasting layers, giving it a distinctive Damascus look. However, the durability, sharpness, and toughness of modern Damascus material are dependent on the types of steel used in the process.

The key difference between true Wootz steel and modern pattern-welded steel lies in the internal structure. True Damascus from the Middle Ages was made from a single type of steel that exhibited unique properties due to its high carbon content and the controlled cooling process used during its creation. In contrast, pattern-welded steel involves combining different materials, such as high-carbon steel and softer iron, which are folded and hammered into one piece.

| Aspect | Damascus Steel (Wootz Steel) | Pattern-Welded Steel |

|---|---|---|

| Origin | Originated in ancient India, later popularized in Syria | Modern recreation, developed to mimic Damascus |

| Composition | High-carbon steel (1-2%), with trace elements like vanadium | Multiple layers of different types of steel |

| Production Process | Single steel type, created using a specific slow-cooling process | Layers of iron and steel are folded and welded |

| Pattern | Natural patterns due to carbide microstructures | Artificially created patterns through layering |

| Sharpness | Known for legendary sharpness and edge retention | Can be sharp, but depends on the steel types used |

| Strength | Strong and tough due to high carbon content and microstructures | Strong but varies based on material combination |

| Flexibility | Balanced hardness and flexibility | Flexibility varies with steel combination |

| Historical Use | Swords, blades, and tools | Primarily modern knives, swords, and art pieces |

| Lost Knowledge | Original method is lost; exact replication is impossible | Easily reproducible through modern techniques |

| Aesthetic Appeal | Natural wave-like patterns unique to each blade | Man-made patterns, often enhanced for visual appeal |

| Metallurgical Properties | Exhibited carbide microstructures for toughness | Varies based on steel composition and layering |

| Edge Retention | Exceptional edge retention | Generally good but varies with steel quality |

While pattern-welded steel shares aesthetic similarities with traditional Damascus, its performance properties can vary based on the materials used in the forging process. Modern steel alloys allow for enhanced durability, but they lack the historical mystique and specific Damascus steel properties that ancient blades were known for.

Composition:

Ancient Damascus steel, also known as Wootz steel, had a unique composition that contributed to its legendary properties. The primary components of ancient Damascus steel are:

Iron (Fe) – The base element of steel, forming the majority of the composition.

Carbon (C) – Wootz steel, the material from which ancient Damascus steel was made, had a high carbon content, typically ranging from 1% to 2%. This is significantly higher than modern steel, giving it exceptional hardness and the ability to form distinctive patterns when forged.

Vanadium (V) – Trace amounts of vanadium were often found in the ore used to make Wootz steel. This element contributed to the formation of carbide microstructures that increased the steel’s toughness and wear resistance.

Manganese (Mn) – Small amounts of manganese, likely introduced through the ore, helped in deoxidizing the steel during its production and contributed to its strength.

Chromium (Cr) – Trace levels of chromium might have been present, although not in the high quantities seen in modern stainless steel. It could contribute to minor corrosion resistance and hardness.

Phosphorus (P) and Sulfur (S) – These were impurities that were present in the steel, typically in very small amounts. While higher levels of phosphorus and sulfur could make steel brittle, their controlled presence in ancient Damascus steel was minimized to maintain its durability.

The process of forging the steel was just as important as its composition. The slow cooling process allowed for the formation of the characteristic carbide bands, which resulted in the beautiful patterns and the hardness of the final product. The combination of high carbon content and trace elements gave ancient Damascus steel its renowned properties—strength, sharpness, and resilience.

Damascus Steel Properties & Composition

One of the main reasons Damascus gained such a legendary reputation is its impressive physical properties. Damascus steel properties include remarkable hardness, edge retention, and toughness, all attributed to the fine microstructures that formed during its creation.

True Damascus material was known for its superior edge retention, meaning that it stayed sharp for longer than many other materials used at the time. This was because of the high-carbon content in Wootz steel, which gave the material its extraordinary cutting ability. Moreover, the steel was able to maintain a fine balance between hardness and flexibility, allowing for weapons and tools that were both strong and resilient to shattering.

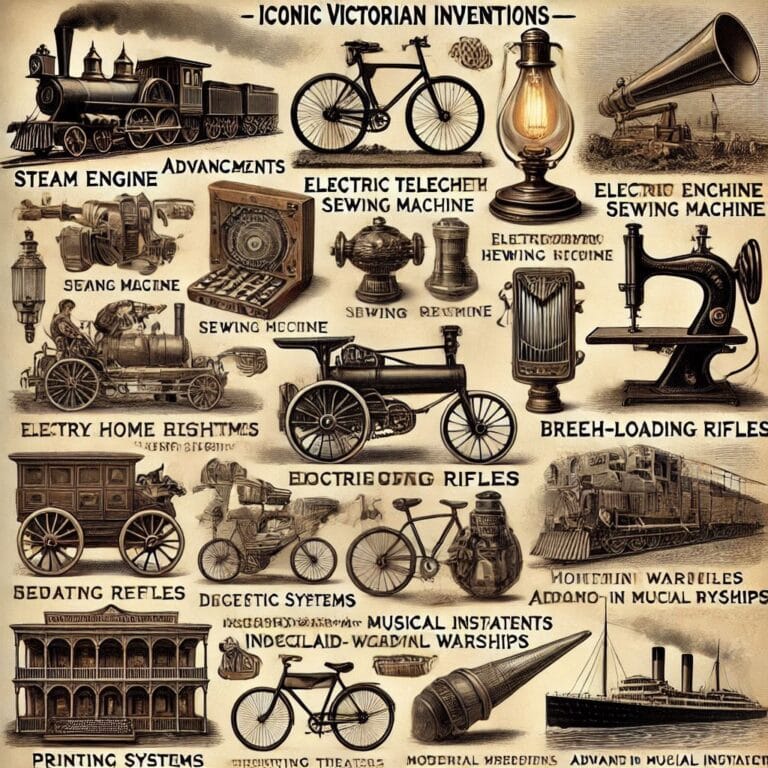

Modern Damascus steel properties, particularly those of pattern-welded steel, are also impressive. By using different alloys such as 15N20 steel and 1084, blacksmiths can produce blades that not only look beautiful but also perform exceptionally well. 15N20 steel contains a high amount of nickel, which creates a striking contrast in the pattern when etched and is often used to enhance the aesthetic appeal of Damascus material.

Damascus knives crafted today are celebrated for their ability to hold an edge longer than standard steel knives. The pattern-welded method also imparts a degree of flexibility to the blades, making them resistant to cracking under pressure. This unique combination of aesthetics and functionality makes Damascus knives highly prized by collectors and professional chefs alike.

Modern Uses and Revival Attempts

The revival of Damascus has captured the imagination of modern blacksmiths and metal enthusiasts alike. While the original technique of making Damascus steel is lost, many artisans have developed new ways of replicating its appearance and, to some extent, its properties. Using high-nickel steels like 15N20 steel and high-carbon steels such as 1084 and 1095, modern Damascus craftsmen attempt to recreate the combination of sharpness and durability that made the material legendary.

Though these modern creations do not exactly replicate ancient Wootz steel, they come close in both appearance and performance. Modern Damascus steel properties are ideal for producing high-quality knives, swords, and even artistic jewelry. Damascus knives, in particular, are highly prized for their durability, edge retention, and aesthetic beauty.

The process of creating modern Damascus material is a labor-intensive craft. Each blade is forged by folding the steel layers numerous times to create intricate patterns. Some blacksmiths also incorporate materials like copper and nickel into their Damascus material to uniquely contrast the blade’s design.

Applications of Damascus Steel Today

Today, Damascus materials can be found in a wide variety of products, from kitchen knives to high-end jewelry. The material’s striking patterns and durability make it popular among collectors and artisans alike. Damascus knives are particularly prized for their sharpness and resilience, making them a preferred choice for chefs and outdoor enthusiasts.

Despite the resurgence of interest in Damascus material, there are still misconceptions about its production. Many people assume that all patterned steel is true Damascus steel, but in reality, the vast majority of Damascus available today is pattern-welded steel. While these blades look similar to ancient Damascus, they are not made using the original process and do not have the same metallurgical properties.

In addition to knives and swords, Damascus material is also used in the creation of luxury items such as rings, watches, and other high-end accessories. The unique patterns make each piece one-of-a-kind, further enhancing the material’s appeal.

Conclusion: The Legacy of Wootz Steel

The legacy of Damascus Steel is one of craftsmanship, mystery, and enduring fascination. Though the original methods of making Damascus material have been lost to time, the material remains iconic for its beauty and legendary strength. Modern blacksmiths continue to explore new ways of recreating this ancient material, while collectors and enthusiasts treasure the unique qualities of Damascus knives and blades.

Whether used in modern applications or admired for its historical significance, wootz steel continues to captivate the imagination of people around the world. Its unique properties, coupled with its beautiful patterns, ensure that it will remain a symbol of excellence in metalwork for generations to come.

Explore our other interesting blogs;