Introduction: Why Lubrication Deserves More Attention

Imagine running a car engine without oil for just a few minutes. What happens?

Friction skyrockets, temperatures soar, and within moments, metal parts begin to warp, seize, or even melt. That’s what importance of lubrication is — not just in vehicles, but across nearly every machine and moving part on Earth.

Despite its quiet role behind the scenes, lubrication is one of the most essential principles in engineering, manufacturing, biology, and even medicine. From massive turbines in power plants to delicate joints in the human body, lubrication keeps systems moving — efficiently, safely, and over long periods.

This blog dives deep into:

- The history of lubricants — from animal fat to synthetic space-grade greases

- The purpose of lubrication and how it improves lifespan, performance, and energy efficiency

- The various types of lubrication and how they differ across machines and industries

- The continuing importance of lubrication in today’s high-tech and environmentally-conscious world

Whether you’re a student, mechanic, engineer, or just a curious mind, this guide will help you see lubrication not as a messy afterthought — but as the invisible engine of progress.

The History of Lubricants: From Animal Fat to Space-Age Fluids

Lubrication may seem like a modern science, but its roots go thousands of years back. From ancient civilizations hauling megaliths to cutting-edge space rovers cruising on Mars, the history of lubricants reflects human progress — one sliding part at a time.

🏺 Ancient Civilizations (2500 BCE – 500 CE): Grease of the Gods

- Egyptians used animal fats and water as early lubricants to move enormous stone blocks for building pyramids.

- Ancient Greeks and Romans used olive oil and beeswax to reduce friction in chariots, war machines, and milling devices.

- Ancient Chinese civilizations used vegetable oils in early metalworking and transportation technologies.

These early lubricants were basic but crucial — allowing movement where friction would otherwise halt or destroy.

⚒️ Middle Ages (500–1500 CE): The Expansion of Plant Oils and Organic Greases

As gears, pulleys, and levers became more common in agriculture and windmills, plant-based oils like linseed, castor, and palm oil became standard.

- Animal tallow and lard were often used in cold environments due to their ability to stay semi-solid.

- Artisans in the Middle Ages found that lubrication helped prevent overheating and damage, making tools last longer.

🚂 The Industrial Age: Rise of Mineral Oils in Manufacturing (1760–1900)

- The invention of the steam engine and later, internal combustion engines, demanded more efficient, heat-resistant lubricants.

- This led to the widespread use of petroleum-derived mineral oils, extracted from crude oil.

- By the late 1800s, major oil companies were refining and selling oils specifically for lubrication — a major leap in industrial performance.

The history of lubricants took a massive leap here — moving from organic to mineral-based oils that could handle extreme loads and temperatures.

🧪 20th–21st Century: Synthetics, Nanotech, and Biodegradable Oils

- The 20th century introduced synthetic lubricants like polyalphaolefins (PAO) and esters, used in aviation, motorsports, and extreme environments.

- Breakthrough compounds like PTFE (Teflon), Molybdenum Disulfide (MoS₂), and lithium greases added specialty properties like water resistance and high-pressure tolerance.

- The space age demanded ultra-stable, vacuum-compatible greases — leading to the invention of space-grade lubricants for satellites and rovers.

- Today, biodegradable and eco-friendly lubricants are on the rise, aiming to reduce environmental impact in agriculture, marine, and food-grade applications.

📊 Timeline Summary

| Era | Lubricant Type | Key Use Case |

|---|---|---|

| Ancient | Animal fats, olive oil | Moving stones, carts, water wheels |

| Middle Ages | Plant oils, tallow | Windmills, plows, hand tools |

| Industrial Era | Mineral oils, paraffin-based oils | Steam engines, textile mills, trains |

| 20th Century | Synthetics, MoS₂, PTFE | Automobiles, planes, electric motors |

| Modern Day | Nano-lubricants, bio-lubricants | Robotics, food-grade systems, space tech |

Purpose of Lubrication: More Than Just “Friction Reduction”

Most people believe the sole purpose of lubrication is to reduce friction — and while that’s certainly important, it’s only one part of a much bigger picture.

In reality, lubrication performs multiple critical roles that affect machine longevity, efficiency, reliability, and even safety. Let’s break down the full spectrum of what lubrication does, with real-world examples from industries, homes, and nature.

🔧 a) Friction Reduction – The Core Purpose

At its most basic, the purpose of lubrication is to reduce friction between two moving surfaces.

- When metal slides against metal — like pistons in an engine — direct contact leads to abrasion, heat generation, and eventual failure.

- Lubricants create a protective film between surfaces, allowing them to glide over each other with minimal resistance.

Example: Engine oil forms a film between pistons and cylinder walls, preventing metal-to-metal contact and dramatically reducing wear and overheating.

Without lubrication, parts would seize and break down in minutes.

🛡️ b) Surface Protection – Shield Against Corrosion & Oxidation

Many environments — especially humid, salty, or chemical-laden — can degrade materials over time.

- Lubricants act as barriers, protecting surfaces from air, water, and contaminants that cause rust, oxidation, and pitting.

- Some lubricants include anti-corrosion additives for long-term protection.

Example: Marine-grade greases protect boat winches and propeller shafts from saltwater corrosion.

❄️ c) Cooling – Carrying Away Heat from Friction Zones

Friction generates heat, and in high-speed machinery or precision operations, even small temperature spikes can lead to thermal expansion, material warping, or fire hazards.

- Lubricants help dissipate heat by absorbing it at the friction point and carrying it away through circulation or conduction.

Cutting fluids in CNC operations help maintain accuracy by dissipating heat from the tool and workpiece, preventing thermal distortion and tool damage.

This cooling effect is an often-overlooked but vital purpose of lubrication in modern manufacturing.

🧼 d) Cleaning – Removing Debris and Contaminants

Lubricants also act as cleaning agents, flushing out:

- Metal shavings

- Dust

- Sludge

- Combustion residues

In circulating systems (like in engines or hydraulics), the lubricant picks up particles and directs them to filters, preventing abrasive build-up.

Example: In hydraulic presses, the oil helps keep internal channels clean and particle-free, improving system reliability and extending equipment life.

💪 e) Power Transmission – Fluid Movement That Does Work

Certain lubricants, especially hydraulic oils, do more than just protect — they’re a working medium used to transmit force.

- Pressurized hydraulic oil moves pistons and actuators in heavy machinery, aircraft systems, elevators, and brake systems.

Example: In an excavator, hydraulic oil delivers power from the pump to the arm, allowing it to lift tons of material — precisely and smoothly.

The purpose of lubrication here shifts from protection to functionality, playing an active role in mechanical systems.

🔇 f) Noise Reduction – Smoother Motion, Quieter Machines

When two surfaces rub or vibrate, they produce noise. Proper lubrication:

- Cushions mechanical contact

- Minimizes metal-on-metal chatter

- Reduces vibration transfer

Example: In HVAC fan motors or industrial conveyor belts, grease helps reduce irritating squeaks and hums, improving workplace comfort and safety.

🧠 Summary: Lubrication Is a Multi-Functional Powerhouse

| Function | Example |

|---|---|

| Friction Reduction | Engine pistons, gearboxes |

| Surface Protection | Marine hardware, food-grade equipment |

| Cooling | CNC machines, high-speed spindles |

| Cleaning | Hydraulic presses, diesel engines |

| Power Transmission | Excavators, airplane landing gear |

| Noise Reduction | Industrial fans, treadmill motors |

Understanding the full purpose of lubrication allows engineers, technicians, and equipment owners to choose the right lubricant for their system — improving performance and reducing downtime.

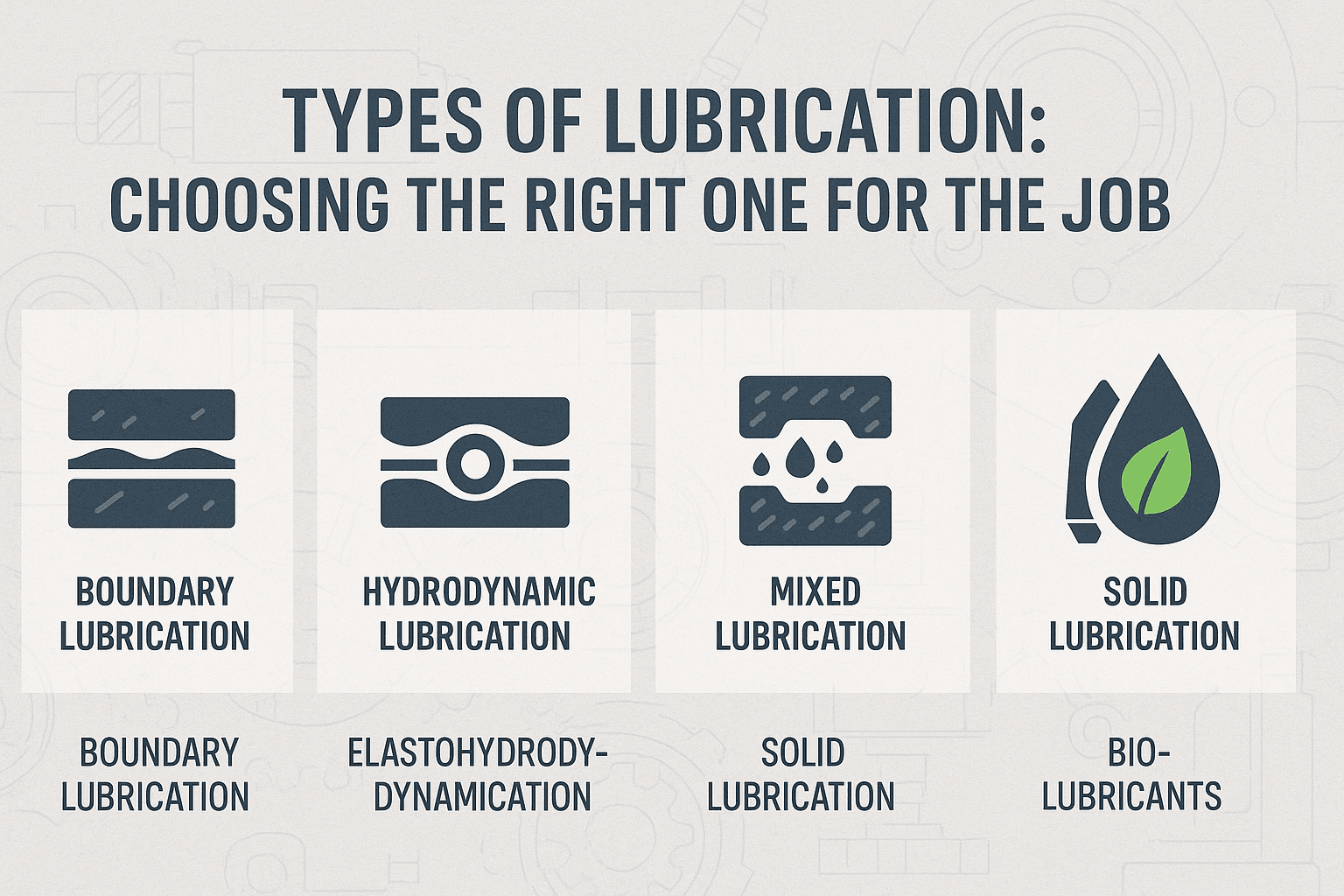

Types of Lubrication: Choosing the Right One for the Job

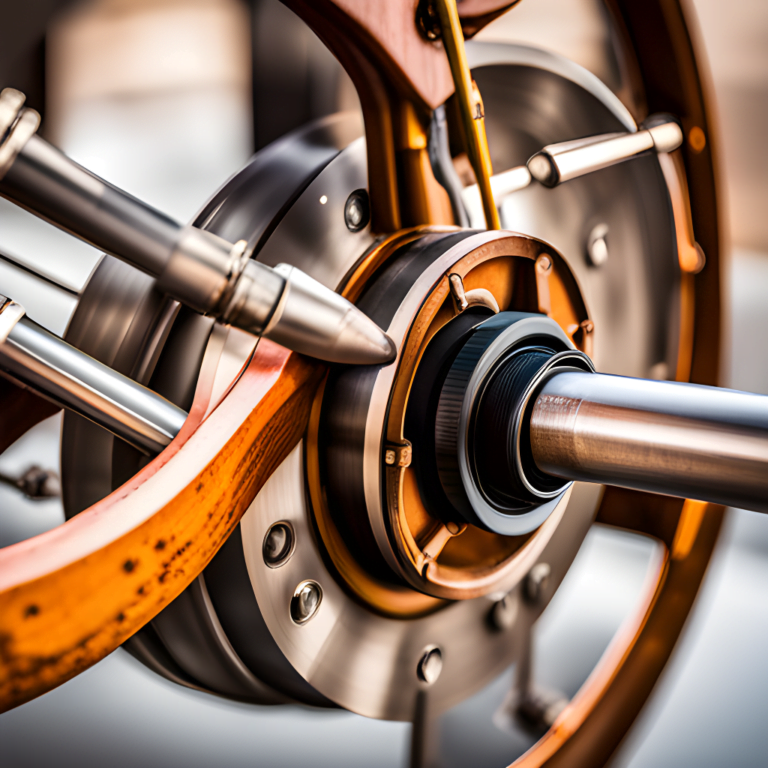

Not all lubricants work the same way. Depending on load, speed, temperature, and application, different types of lubrication are used to protect surfaces, reduce wear, and optimize performance.

Choosing the right type isn’t just about picking oil or grease — it’s about understanding the lubrication regime. Let’s explore the six main types and when to use each, along with real-world examples.

🔹 a) Boundary Lubrication

This type occurs when lubricant films are very thin, often just a few molecules thick. It’s common in high-load, low-speed environments where the surfaces may still touch intermittently.

- Key Features:

– Minimal oil film thickness

– Protective chemical additives like ZDDP (zinc dialkyldithiophosphate) form anti-wear layers

– Prevents scoring and metal-to-metal contact - Use Cases:

– Gearboxes

– Camshafts and tappets

– Cold-start engine conditions

Boundary lubrication is critical in startup and shock-load situations, where full fluid separation isn’t possible.

🔹 b) Hydrodynamic Lubrication

This is the ideal lubrication type, where a full fluid film completely separates moving surfaces — no direct contact occurs.

- Key Features:

– Continuous oil film

– Minimal wear

– Requires relative motion and sufficient speed - Use Cases:

– Engine crankshafts

– Journal bearings

– Rotating shafts in industrial fans

Hydrodynamic lubrication is efficient but only forms when motion is fast enough and the load is moderate.

🔹 c) Elastohydrodynamic Lubrication (EHL)

A more advanced form of lubrication, EHL occurs in high-pressure, small contact zones, such as in ball bearings and gear teeth.

- Key Features:

– Extremely thin, pressurized oil film

– Temporary elastic deformation of surfaces

– Rapid pressure buildup ensures separation - Use Cases:

– Rolling element bearings

– Hypoid gears in axles

– High-speed transmission systems

EHL ensures protection even when contact areas are microscopic and heavily loaded — making it essential for precision mechanical systems.

🔹 d) Mixed Lubrication

As the name suggests, this is a hybrid of boundary and hydrodynamic lubrication.

- Key Features:

– Partial surface contact

– Thin fluid film with intermittent boundary zones

– Occurs during transitions (e.g. start-up or slow-down) - Use Cases:

– Piston rings in car engines

– Variable-speed gear systems

– Hydraulic actuators

This is the most common lubrication state in real-world machines — especially those that operate across variable speeds and loads.

🔹 e) Solid Lubrication

Used in extreme environments where traditional oils or greases would evaporate, freeze, or burn.

- Common Materials:

– Graphite

– Molybdenum Disulfide (MoS₂)

– PTFE (Teflon) - Use Cases:

– Spacecraft mechanisms

– High-temperature industrial ovens

– Vacuum chambers

– Dry sliding surfaces

Solid lubricants are crucial in conditions where liquid lubrication fails, like outer space or extremely high-heat machinery.

🔹 f) Grease vs Oil vs Dry Lubricants

To simplify your selection process, here’s a comparison of the most common forms of lubrication:

| Lubricant Type | Best For | Advantages | Examples |

|---|---|---|---|

| Oil | High-speed, circulating systems | Excellent heat transfer & flow | Engines, gearboxes |

| Grease | Moderate-speed, enclosed or sealed parts | Stays in place, resists washout | Bearings, electric motors |

| Dry (Solid) | Harsh, dry, or vacuum environments | Works under extreme temps or zero-G | Space mechanisms, oven chains |

🌱 Bio-Lubricants (The Sustainable Alternative)

Driven by environmental concerns, the demand for eco-friendly lubricants made from plant-based oils is on the rise.

- Common sources include renewable oils like soybean, sunflower, and canola

- Biodegradable and low-toxicity

- Suitable for sensitive applications (e.g. forestry, marine, agriculture)

Use Cases:

- Chain saw oils in forests

- Hydraulic oils for boats

- Greases in food processing plants

As sustainability becomes a design priority, bio-lubricants represent the future of lubrication across industries.

The Importance of Lubrication: In Machines, Medicine & More

Lubrication isn’t just about oiling gears — it’s a foundational principle that drives productivity, prevents failure, and even supports life itself. The importance of lubrication stretches across industry, economics, and biology — quietly influencing the way machines, markets, and human bodies operate every day.

Let’s explore this through three powerful lenses.

🏭 a) Industrial Importance

In industries like automotive, aerospace, manufacturing, construction, and robotics, the role of lubrication is nothing short of mission-critical.

Why It Matters:

- Reduces wear & tear → prolongs equipment life

- Minimizes overheating → lowers fire and breakdown risks

- Enables smoother operation → improves energy efficiency

- Prevents unplanned downtime → ensures production reliability

In jet engines, even a micron-thin film of oil prevents turbine blades from grinding themselves apart at 20,000 RPM.

Use Cases:

- CNC machining centers rely on cutting fluids to prevent overheating during metal shaping

- Wind turbines use high-performance synthetic grease in gearbox bearings for 24/7 reliability

- Automated factories use centralized lubrication systems to maintain uptime and robotic accuracy

The importance of lubrication here lies in its ability to preserve millions of dollars’ worth of machinery and prevent catastrophic failure.

💰 b) Economic Impact

Lubrication isn’t just a mechanical necessity — it’s also a financial safeguard. Every drop of effective lubrication adds measurable value to businesses worldwide.

Global Stats:

- The global lubricant market was valued at over $130 billion in 2023, driven by demand in automotive and industrial sectors

- Poor lubrication is responsible for up to 50% of all mechanical failures

- Efficient lubrication can reduce energy consumption in machines by up to 20%

Real-World Example:

Case Study: Plant A (India)

By switching from conventional mineral oil to a high-grade synthetic lubricant, Plant A reduced:

- Equipment downtime by 18%

- Maintenance labor hours by 25%

- Annual maintenance costs by ₹5 lakhs

They also achieved a 10% energy saving due to reduced internal resistance in hydraulic systems.

This shows that the importance of lubrication isn’t just technical — it’s tied directly to a company’s bottom line.

🧬 c) Biological & Medical Relevance

Few people realize that lubrication is essential to life itself. The human body contains natural lubricants, and modern medicine replicates this principle for healing and motion.

Synovial Fluid:

- A natural lubricant found in human joints

- Enables smooth, pain-free movement in knees, hips, fingers, and more

- Reduces bone-on-bone friction and dissipates shock

Without synovial fluid, every joint movement would feel like grinding sandpaper — eventually leading to damage and pain.

Artificial Joints & Prosthetics:

- Hip and knee replacements use medical-grade synthetic lubricants to replicate the function of synovial fluid

- Long-lasting performance relies on friction control between implant components

Surgical & Diagnostic Equipment:

- High-precision tools like robotic surgery arms use micro-lubrication to ensure clean, accurate, and frictionless motion

- MRI tables, infusion pumps, and ventilators all depend on reliable lubrication

Clinical Insights:

Research has shown that properly lubricated implants can last 15–20 years, whereas poorly lubricated ones may fail within 5–7 years — leading to costly revisions and increased patient suffering.

The importance of lubrication in medicine isn’t just mechanical — it’s about human mobility, health, and comfort.

Common Lubrication Mistakes and How to Avoid Them

Even with the best products, poor lubrication practices can damage equipment, waste money, and create safety risks. Understanding the most common lubrication mistakes — and how to avoid them — adds immense practical value for technicians, engineers, and maintenance teams alike.

Here’s a breakdown of frequent errors and the smart habits that prevent them.

❌ Over-Greasing Bearings

Too much grease increases friction, causes overheating, and may even blow seals — leading to contamination.

✅ Tip: Use a grease gun with a metered output or automatic lubricators to apply just the right amount based on OEM specs.

⚠️ Mixing Incompatible Lubricants

Combining different types (e.g. lithium-based grease with calcium-based) can cause:

- Thickening or thinning

- Poor film strength

- Lubricant breakdown

✅ Tip: Always refer to the lubricant compatibility chart and flush systems before switching types.

🛢️ Using the Wrong Viscosity Grade

Viscosity that’s too high can cause drag and heat; too low may fail to form a protective film.

✅ Tip: Match the viscosity grade (e.g. ISO 32, 68, 100) to the equipment’s speed, load, and temperature — never assume “one size fits all.”

🧪 Ignoring Contamination

Contaminants like dirt, moisture, and metal particles degrade lubricant performance and speed up equipment wear.

✅ Tip: Keep containers sealed, use clean tools, and install breather filters or desiccant breathers in storage and in-system.

🔍 Skipping Routine Oil Analysis

Failing to test oil condition means missing early warning signs of failure like:

- Increased wear metals

- Water ingress

- Additive depletion

✅ Tip: Use oil analysis reports every 3–6 months to track lubricant health and schedule proactive maintenance.

✅ Quick Checklist: Lubrication Best Practices

| Do | Don’t |

|---|---|

| Use OEM-recommended lubricants | Assume all greases or oils are the same |

| Label storage containers clearly | Mix old and new lubricants |

| Conduct regular oil analysis | Wait for signs of failure |

| Train staff on lube procedures | Rely on guesswork |

| Store in clean, dry environments | Leave containers open to air/moisture |

📄 Bonus: Offer a downloadable PDF: “Lubrication Do’s and Don’ts” to boost engagement and retention.

Future of Lubricants: Sustainability & Smart Monitoring

As machines and industries evolve, so must the lubricants that keep them running. The future of lubrication lies in smart sensors, eco-conscious formulas, and AI-powered diagnostics — all helping reduce downtime and environmental harm.

Here’s what’s shaping the next decade of lubrication:

🌱 Biodegradable & Plant-Based Lubricants

- Made from canola, soybean, sunflower oils

- Non-toxic, biodegradable, and safer for marine, food-grade, and forestry applications

- Compliant with environmental regulations like EPA’s EAL (Environmentally Acceptable Lubricants)

As green manufacturing rises, bio-lubricants will soon become standard in sensitive industries.

📶 IoT & Smart Lubrication Systems

- Smart sensors monitor:

- Lubricant level

- Viscosity changes

- Temperature and pressure

- Predictive alerts for refill or contamination

- Wireless data sync to maintenance dashboards

Example: Wind turbines in remote areas use smart lube sensors to detect degradation and schedule preventive service — saving costly emergency repairs.

🧠 AI-Based Oil Condition Monitoring

- AI tools analyze data from oil samples or in-line sensors

- Predict:

- Additive depletion

- Wear particles

- Contamination sources

- Enables predictive maintenance, not just reactive

🧽 Self-Lubricating Materials

- Polymers or composites embedded with dry lubricants like graphite or PTFE

- Used in aerospace, medical implants, and robotics

- Eliminate the need for external oil or grease in some designs

⚡ Lubrication for Electric Vehicles (EVs)

- EVs require low-viscosity oils for cooling electronics, gearbox protection, and battery thermal regulation

- Thermal fluids are now dual-purpose: lubricate + cool power systems

The future of lubricants lies in being smarter, cleaner, and more deeply integrated into systems than ever before.

📈 Content Gap Filled:

Few articles address the next-gen side of lubrication. Including biolubes, AI, and smart sensors positions your blog as future-ready and adds high topical authority — especially valuable for long-term SEO.

Conclusion: A Silent Hero of Machines (and Life Itself)

From ancient animal fats to AI-monitored nano-lubricants, lubrication has quietly powered every mechanical revolution in history.

Throughout this post, we explored:

- The history of lubricants — and how they evolved alongside civilization

- The purpose of lubrication — beyond just friction control

- Different types of lubrication — tailored for load, speed, and environment

- The importance of lubrication in industry, economy, and even human biology

- Common mistakes to avoid — and where the future of lubrication is heading

This simple science of “slippery substances” remains one of the most vital forces behind modern machines, sustainable operations, and quality of life.

💬 Call to Action:

- Got a favorite lubricant brand or a mistake you learned the hard way? Share it in the comments!

- Working in industry? Check out our related post: [How to Choose the Right Industrial Oil]

- New to lubrication? Read: [Grease vs Oil Explained – When to Use Each]

- Don’t forget to subscribe for more engineering deep dives and practical guides.

Explore More Ancient Innovations:

If you’re fascinated by how lubrication has played a role in shaping mechanical progress, you’ll love diving deeper into humanity’s engineering past. Don’t miss these related reads:

-

The History of Cranes – Discover how lifting technology evolved from simple pulleys to modern giants.

-

Ancient Metallurgy: The Evolution of Metalworking Techniques – See how early civilizations transformed raw ore into powerful tools and weapons.

-

The Invention of Iron – Learn how this pivotal discovery reshaped agriculture, warfare, and infrastructure.

-

Damascus Steel – Uncover the mystery behind the legendary metal known for its strength and beauty.

-

The Invention of Gunpowder – Understand how a simple mixture changed the course of warfare and innovation.

-

9 Advanced Ancient Technologies That Were Ahead of Their Time – Explore mind-blowing technologies from the past that still amaze scientists today.