Introduction: The Origin of Metallurgy

Imagine a world where humans first learned to extract and shape metals from the earth. The discovery of ancient metallurgy revolutionized early societies, shaping the tools, weapons, and infrastructure that fueled the rise of civilizations. This early mastery over metals is not only a technological achievement but a gateway that sparked the growth of agriculture, trade, and warfare.

Metallurgy, at its core, is the science of extracting metals from ores, refining them, and shaping them into useful materials. It encompasses everything from the study of the physical and chemical properties of metals to their practical applications in creating tools, alloys, and industrial structures. This ancient craft played a crucial role in the evolution of human civilization, providing the foundation for advances in construction, medicine, and more.

The impact of metallurgy on world history is immeasurable. Early advancements in the study of metals allowed ancient civilizations like Mesopotamia, Egypt, and the Indus Valley to develop bronze and iron, which were used to create weapons and tools that fueled empires. In ancient India, for example, metallurgical techniques like the creation of Wootz steel became world-renowned for their strength and durability. Through ancient metallurgy, civilizations were able to build strong infrastructures and forge powerful armies, advancing human society into new eras of innovation and trade.

This essay traces the fascinating journey of ancient metallurgy, exploring its origins, pivotal contributions from different civilizations, and its lasting legacy. Explore the ancient metallurgy origin and its lasting impact on the study of metals through time.

The Dawn of Metallurgy

Early Metal Use:

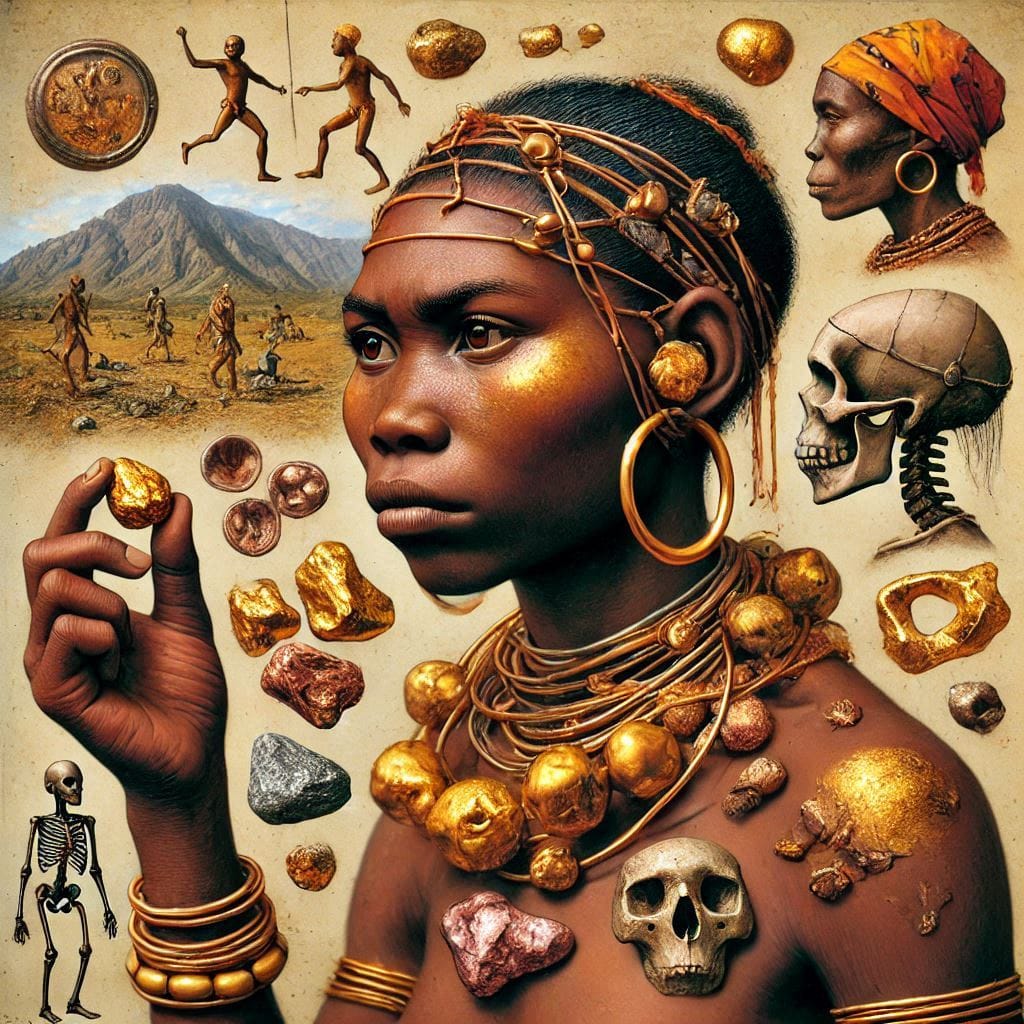

The origin of metallurgy can be traced back to the earliest interactions of humans with naturally occurring metals like gold, silver, and copper. These metals were first used in their raw form, without the need for smelting or complex processing. Gold, due to its rarity, softness, and lustrous quality, was initially used for crafting jewelry and decorative items. Silver followed a similar path as a precious metal, used for ornaments and religious artifacts. The use of copper marked a significant step in early metallurgy, being the first metal to be shaped into tools and weapons. Prehistoric humans discovered that native copper, when hammered, could form rudimentary tools. These early applications of naturally occurring metals set the foundation for more advanced metallurgical practices.

Pioneering Techniques:

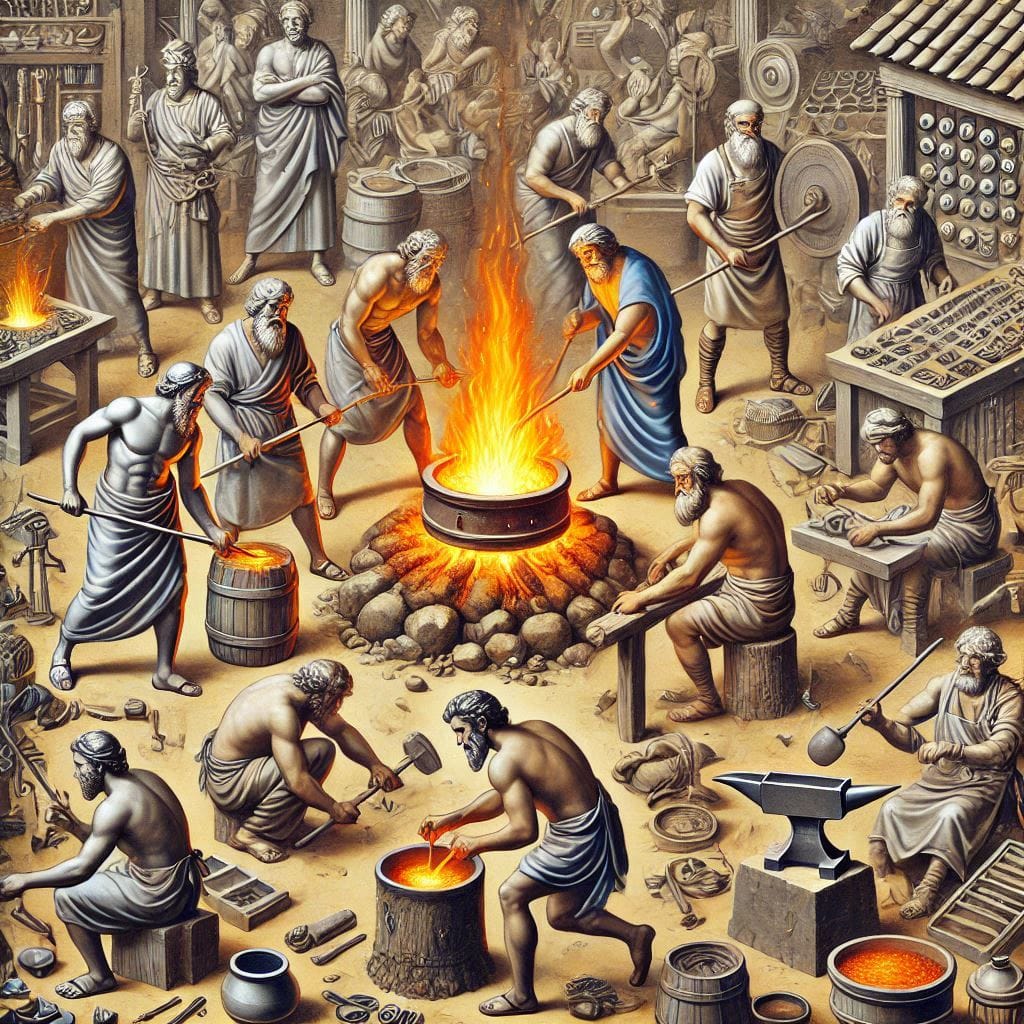

The transition from using native metals to more complex smelting techniques was a monumental shift in ancient metallurgy. Smelting, the process of extracting metal from its ore by heating it to high temperatures, required a deeper understanding of temperature control, fuel sources, and the use of reducing agents such as carbon. Early smelting methods were rudimentary but paved the way for the sophisticated metallurgical practices that emerged in later civilizations.

One of the key aspects of smelting was mastering the control of temperature. Ancient metallurgists discovered that different metals required specific temperature ranges to separate them from their ores. The introduction of charcoal as a fuel source enabled higher temperatures than wood, making it an essential component in early smelting furnaces. These early furnaces evolved into more advanced kilns, allowing the extraction of metals like copper and tin, which were combined to create the alloy bronze.

Significant ancient metallurgical sites like Çatalhöyük in Turkey, Çayönü in southeastern Anatolia, and Varna Cemetery in Bulgaria provide insights into the development of these techniques. At Çatalhöyük, evidence suggests that early humans were experimenting with copper smelting as far back as 7,000 BCE. Similarly, the Varna Cemetery, which dates back to 4,500 BCE, is known for its rich collection of copper and gold artifacts, underscoring the early use of metallurgy in crafting tools, ornaments, and religious symbols. These sites offer critical clues about the socio-economic implications of metallurgy, highlighting how the study of metals led to the rise of specialized craftworkers and trade networks that linked distant regions.

Metallurgy in Ancient Civilizations

Mesopotamia and the Indus Valley:

Ancient India metallurgy reached new heights in places like Mesopotamia and the Indus Valley, where advanced smelting techniques were used to produce bronze. The Indus Valley civilization, which flourished around 3300–1300 BCE, was particularly known for its mastery of lost-wax casting. This technique enabled artisans to create intricate metalworks, including jewelry, tools, and ceremonial items. Similarly, in Mesopotamia, the use of bronze, an alloy of copper and tin, revolutionized toolmaking and weaponry. The emergence of bronze allowed for the development of stronger and more durable implements, which in turn facilitated the growth of cities and the expansion of trade networks.

The role of metallurgy in these regions was not limited to tools and weapons; it also played a critical role in the socio-economic structure of early urban civilizations. The rise of specialized craftspeople in metalworking spurred trade in metals, creating economic hubs in places like Uruk and Babylon, and contributing to the flourishing of Mesopotamian urban life.

Egypt and China:

In Ancient Egypt, copper smelting techniques were advanced for their time, and the production of bronze alloys became an integral part of Egyptian society. The Egyptians used these materials not only for weaponry but also for monumental architecture, such as the pyramids, and for religious artifacts. The use of bronze in Egyptian culture helped define the civilization’s power and prestige.

China’s contributions to metallurgy were similarly transformative. The Chinese were among the first to develop iron production around the 5th century BCE. Early Chinese ironworkers used the blast furnace to produce iron, which revolutionized both military technology and agricultural practices. Iron tools and weapons allowed for increased agricultural output and more effective defense against external threats, further consolidating the strength of early Chinese dynasties. Additionally, the Chinese developed bronze alloys that were widely used in ceremonial contexts, illustrating the complex and multifaceted role of metallurgy in Chinese society.

Ancient India Metallurgy:

India is renowned for its metallurgical innovations and study of metals particularly the creation of Wootz steel, which became highly sought after for its remarkable strength and durability. Wootz steel was produced using a unique process involving high-carbon iron, making it ideal for crafting swords and weapons that could hold sharp edges even after prolonged use. This steel was traded widely, reaching as far as the Roman Empire and contributing to India’s reputation as a center of advanced metallurgy.

In addition to Wootz steel, India also played a key role in the development of Damascus steel, a legendary material known for its patterning and resilience. Indian metallurgists were also known for their use of various alloying elements, further enhancing the properties of their metals. The role of metallurgy in Indian art, architecture, and spirituality was equally significant, with metals being used in the creation of religious sculptures, temple architecture, and royal regalia. Notable examples of ancient Indian metallurgy include the Iron Pillar of Delhi, which is famous for its resistance to corrosion despite being over 1,600 years old.

These contributions to metallurgy helped shape Indian society, fueling trade and enriching cultural and spiritual practices. The significance of Ancient India Metallurgy cannot be overstated, as it laid the foundation for both technological advancement and artistic expression.

Advancements in Metal Technologies

The Bronze Age

The Bronze Age marked a pivotal shift in metallurgy, primarily driven by the transition from copper to bronze, an alloy of copper and tin. This alloy offered several key advantages over pure copper. Bronze is stronger, more durable, and has a higher resistance to corrosion, making it ideal for creating tools, weapons, and artifacts. The advent of bronze metallurgy allowed societies to forge more advanced weapons like swords and shields, which had a direct impact on warfare. Tools made from bronze were also more effective in agriculture, allowing for more efficient plowing and harvesting.

The development of bronze alloys was a significant technological leap, as metallurgists experimented with various proportions of copper, tin, and sometimes other elements like arsenic and lead. Each variation in the alloy’s composition imparted unique properties to the metal, such as increased hardness or improved casting capabilities. Bronze was not only a material for warfare and agriculture but also played an integral role in cultural expressions through art and monumental structures. Bronze statues, jewelry, and ceremonial items became central to the social and religious practices of the time.

The widespread use of bronze revolutionized trade, as regions rich in copper and tin began to establish robust trade networks. The Bronze Age is often seen as a time when societies moved from simple agrarian communities to more complex urban civilizations, with metallurgy playing a crucial role in shaping this development.

The Iron Age

The Iron Age followed the Bronze Age and was heralded by the discovery of iron smelting, a transformative advancement in metallurgy. The process of extracting iron from its ore, which typically involves heating iron ore with charcoal in a furnace, had significant consequences for ancient civilizations. Iron’s abundance compared to tin (needed for bronze) made it a far more accessible material for tool and weapon production. The discovery of iron smelting gave rise to stronger and more versatile metals, which were essential for the development of warfare, agriculture, and industry.

The development of iron-working techniques, including forging, casting, and heat treatment, revolutionized metalworking. Forging involved hammering hot iron into desired shapes, while casting allowed for the creation of more intricate and complex forms. Heat treatment, such as quenching and tempering, allowed metallurgists to control the hardness and toughness of the iron, making it more effective for tools and weapons.

The Iron Age had a profound impact on society. Iron was used to craft weapons, which enabled the growth of powerful armies and the expansion of empires. Iron plows improved agricultural productivity, which in turn supported the growth of larger populations and more complex economies. The widespread use of iron also facilitated the production of essential goods for everyday life, such as cooking utensils, construction tools, and infrastructure components.

Iron and Steel Production

The evolution of iron and steel production technologies marked the beginning of a new era in metallurgy. Blast furnaces, which were developed in China around the 5th century BCE, allowed for the mass production of iron, increasing its availability for industrial use. The puddling process, introduced in the 18th century, was another breakthrough that led to the creation of steel—a stronger and more versatile metal than iron. This process involved agitating molten iron to eliminate impurities, resulting in a purer, higher-quality material.

The Industrial Revolution had a significant impact on iron and steel production, with innovations such as the Bessemer process and open-hearth furnace making steel production faster and more efficient. The increased availability of steel led to its widespread use in construction, transportation (railways and ships), and military equipment. The ability to mass-produce steel changed the landscape of industries globally and paved the way for the development of modern infrastructure.

The industrialization of iron and steel production not only affected economies but also reshaped societies. Steel played a pivotal role in the development of skyscrapers, bridges, and the automotive industry, marking the transition into the modern technological age.

Metallurgy’s Role in Society and Culture

Metal Artifacts

The ancient civilizations’ use of metal transcended mere utilitarian function, with metal artifacts spanning a vast range of tools, weapons, jewelry, and religious objects. These objects were not only integral to daily life but also served to symbolize status, power, and divine favor. Tools such as axes, hammers, and knives were crafted with bronze or iron to provide efficiency in agriculture and construction. Meanwhile, weapons like swords and spears, often forged from bronze or later iron, marked the advancement of military technology, greatly impacting warfare strategies and empire-building.

In addition to their practicality, metal artifacts were also a medium for artistic expression. Jewelry, for instance, ranged from simple adornments to elaborate pieces with intricate designs made from gold, silver, and bronze. These items were often symbols of wealth, authority, and religious significance. Religious artifacts, like bronze statues and ceremonial tools, were often crafted to honor gods and deities, serving both spiritual and political purposes.

Metallurgical advancements, such as casting techniques, lost-wax casting, and forging, shaped these metal artifacts’ aesthetic and functional qualities. These developments enabled the creation of more detailed and durable objects, illustrating the sophisticated understanding of metalworking by ancient civilizations.

Economic and Cultural Impact

Metallurgy played a significant role in the economic landscape of ancient civilizations. The trade of metal goods, particularly bronze, gold, and silver, formed the backbone of early economies. Metal trade routes connected distant regions, facilitating cultural exchange and the spread of technological innovations. For example, the development of bronze metallurgy in the ancient Near East was propelled by the exchange of tin and copper. The economic significance of these metal trade routes was also evident in the rise and fall of empires, as civilizations with access to superior metals gained military advantages and expanded their influence.

The cultural impact of metallurgy was profound, shaping art, architecture, and religion. Architectural achievements, such as the construction of temples and palaces, often involved the use of metal tools and materials. Religious artifacts, including metal statues and sacred objects, were crafted to convey divine messages, with metals symbolizing strength, purity, and eternity. In Egypt, for instance, gold and copper were used extensively in religious and funerary contexts, symbolizing the gods’ immortality and protection in the afterlife.

Moreover, metallurgy played a pivotal role in shaping social hierarchies and power structures. The ability to control the production and distribution of metals gave elites power and influence over trade and warfare. Metalworking became a highly specialized skill, often passed down through generations, creating an economic division between metalworkers and the general population.

The Science Behind Ancient Metallurgy

Archaeometallurgy

Modern archaeometallurgical techniques have revolutionized our understanding of the study of metals offering detailed insights into the technological processes of ancient metalworkers. Techniques such as isotopic analysis, metallographic examination, and X-ray fluorescence spectroscopy allow archaeologists to trace the origins of metals, study the microstructures of ancient artifacts, and understand the trade networks that existed in antiquity.

Isotopic analysis helps identify the geographical origin of metal ores, while metallographic examination provides a view into the material’s microstructure, revealing the production methods and alloying techniques used by ancient metallurgists. X-ray fluorescence spectroscopy enables the non-destructive analysis of metals, allowing researchers to identify the elemental composition of ancient artifacts without damaging them.

Case studies have demonstrated the effectiveness of these techniques. For example, isotopic analysis has revealed trade routes that linked civilizations in Mesopotamia with regions rich in copper and tin, facilitating the development of bronze metallurgy. Metallographic analysis has shown that ancient Egyptian copper smelting techniques were remarkably advanced, allowing them to produce high-quality metal tools and weapons.

Metallurgical Analysis of Ancient Artifacts

The metallurgical analysis of ancient artifacts offers a deeper understanding of the technological capabilities and knowledge of early metalworkers. By examining the composition, microstructure, and manufacturing techniques of artifacts, researchers can reconstruct how different metals were processed and shaped. For example, the composition of bronze artifacts found in ancient Sumerian ruins suggests a sophisticated understanding of alloying techniques, combining copper and tin to create a stronger, more durable material.

Analysis of manufacturing techniques can also reveal the methods used in crafting intricate pieces, such as the lost-wax casting process, which was used by ancient civilizations to create detailed metal sculptures and jewelry. This process, which involves creating a wax model that is then covered in clay and heated to remove the wax, was an essential technique for producing finely detailed metal artifacts.

By examining the microstructures of ancient metal objects, researchers can uncover the knowledge and skills passed down through generations, revealing the evolution of metallurgy and how it shaped the technological progress of ancient societies.

The Legacy of Ancient Metallurgy

Lessons from the Past

The study of ancient metallurgy offers invaluable insights that continue to shape modern practices, especially in the development of sustainable and environmentally friendly materials. Ancient metallurgists used local resources, often relying on natural ores, and created processes that minimized waste. These techniques can inspire contemporary metallurgists to adopt more efficient and eco-friendly methods, particularly as we strive to reduce the environmental impact of modern industries. Preserving and studying ancient metallurgical sites and artifacts, such as those at Çatalhöyük and Çayönü, is crucial for understanding the past and applying its lessons to modern challenges. These sites not only provide evidence of early technological innovations but also highlight the ingenuity of ancient societies in adapting to their environments with minimal resources.

Inspiring Future Innovations

Ancient discoveries in metallurgy continue to fuel future innovations. Drawing from the early techniques of metal smelting and alloying, today’s metallurgists are working on creating stronger, lighter, and more durable materials for industries such as aerospace, medicine, and electronics. For example, the unique properties of ancient Wootz steel, renowned for its strength and durability, continue to inspire research in modern high-performance alloys. In the context of modern challenges like climate change and resource scarcity, metallurgy plays a crucial role. By revisiting ancient methods, such as those used to extract metals from ores with minimal energy, we can contribute to sustainable mining practices and green technologies. Additionally, recycling ancient metals and applying modern smelting techniques can reduce the reliance on new raw materials and lower carbon footprints.

FAQ

What is ancient metallurgy and why was it important?

Ancient metallurgy refers to the study and practice of extracting, refining, and shaping metals by early civilizations. It was crucial because it enabled humans to make stronger tools, weapons, and structures, marking the transition from the Stone Age to the Bronze and Iron Ages.

Which was the first metal used by humans?

Copper is widely considered the first metal used by humans, dating back to around 9000 BCE. Its malleability made it easy to shape into tools and ornaments, laying the foundation for more advanced metallurgical techniques.

How did ancient civilizations discover alloying techniques?

Early metalworkers discovered that combining copper with tin created bronze, a much harder and more durable material. This discovery around 3300 BCE sparked the Bronze Age, revolutionizing agriculture, warfare, and trade.

What role did metallurgy play in ancient economies?

Metallurgy fueled trade networks by creating valuable goods such as weapons, jewelry, and coins. Civilizations like Mesopotamia, Egypt, and the Indus Valley prospered because they controlled access to metal resources and advanced smelting techniques.

How did ancient people smelt metals without modern furnaces?

They built primitive furnaces or pit kilns fueled by charcoal, using bellows to increase oxygen flow. This allowed them to reach high temperatures sufficient to extract copper, tin, iron, and eventually steel.

What was the significance of iron in ancient history?

Iron marked a major leap forward around 1200 BCE. Unlike bronze, iron ore was widely available, making iron tools and weapons cheaper and more accessible. The Iron Age enabled the rise of powerful empires with advanced military and agricultural systems.

Did ancient metallurgy influence art and culture?

Yes. Beyond tools and weapons, metals were used for jewelry, ceremonial objects, and religious artifacts. Gold and silver held symbolic importance, often associated with divinity, wealth, and political power.

How does modern metallurgy trace its roots to ancient techniques?

Modern metallurgy builds on principles first developed in antiquity, such as smelting, alloying, and forging. Today’s high-tech industries—like aerospace, construction, and electronics—still rely on the basic discoveries made thousands of years ago.

Conclusion

The journey through ancient metallurgy reveals the ingenuity and adaptability of early civilizations, whose metalworking techniques laid the foundation for the modern materials that power today’s industries. From the birth of bronze to the development of iron and steel, these discoveries not only transformed ancient societies but also provided a legacy of technological and cultural advancements that continue to inspire contemporary innovations. By studying the origin of metallurgy and the study of metals, we gain a greater understanding of the critical role metals play in shaping human history and how these timeless principles can help address the challenges of the future. As we move towards a more sustainable and innovative future, the lessons from ancient metallurgy will continue to inform and inspire, ensuring that our technological progress honors the ingenuity of the past.

If you enjoyed exploring the legacy of ancient metallurgy, don’t miss my related blogs on fascinating topics like The Invention of Iron, Damascus Steel, The Invention of Gunpowder, and 9 Advanced Ancient Technologies That Were Ahead of Their Time. Dive deeper into the incredible innovations and engineering marvels of the past!