Introduction

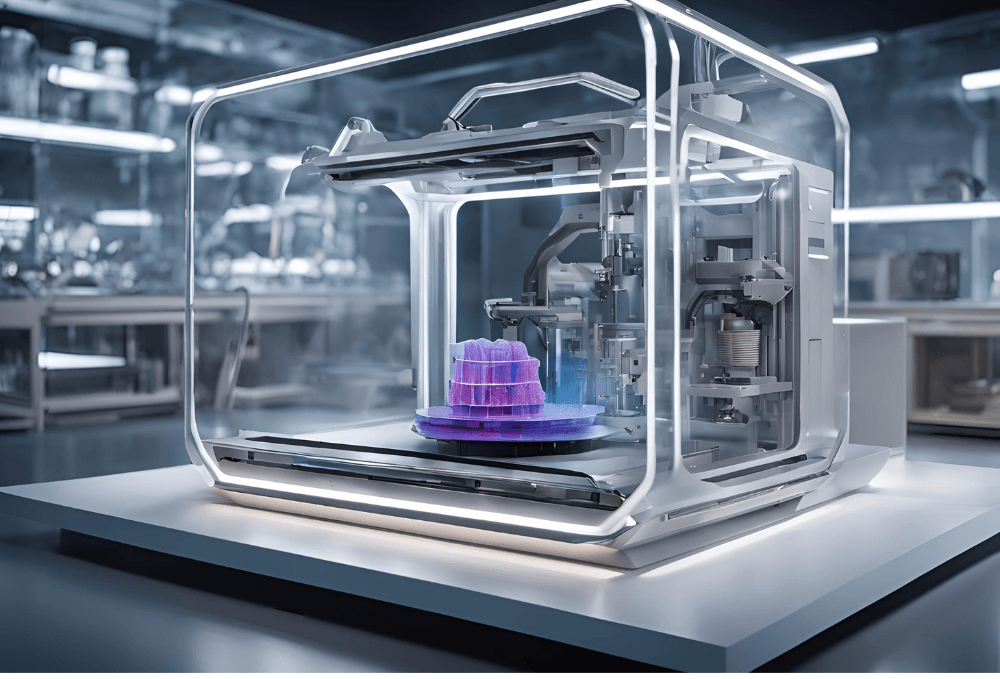

4D printing technology is a revolutionary advancement that builds upon the foundation of 3D printing by incorporating smart materials capable of changing shape or properties over time in response to environmental stimuli. Unlike static 3D-printed objects, 4D printing technology enables structures to self-transform, adapt, and even repair themselves based on programmed instructions embedded within the material.

This breakthrough has significant implications across various industries, particularly in construction and biomedical fields. In construction, 4D printing has the potential to create self-assembling structures, reducing labor costs and improving efficiency. In the biomedical sector, smart materials in 4D printing can lead to innovations such as self-folding medical implants and responsive drug delivery systems.

Despite its potential, 4D printing technology encounters numerous challenges. The complexity of designing programmable materials, the need for precise control over transformation behaviors, and the high cost of implementation are key hurdles. However, ongoing research and advancements in smart materials in 4D printing suggest that this technology will become more refined and accessible in the future.

What Is 4D Printing Technology?

4D printing is an innovative manufacturing process that extends 3D printing by using programmable materials that can transform in shape, function, or properties over time. These changes are triggered by external stimuli such as temperature, moisture, pH, or light, making 4D printing technology a dynamic evolution of additive manufacturing.

How 4D Printing Differs from 3D Printing

Traditional 3D printing fabricates fixed, static objects from materials like plastics, metals, or ceramics. In contrast, 4D printing technology integrates smart materials that can morph or react to environmental conditions without additional mechanical input. This adaptability enables applications in various domains, from self-healing infrastructure to responsive textiles and biocompatible medical devices.

Scientific Principles Behind 4D Printing

The core concept of 4D printing technology relies on the use of smart materials in 4D printing, which include:

- Shape-memory polymers (SMPs): These materials can return to a pre-programmed shape when exposed to specific triggers such as heat or light.

- Hydrogels: Often used in biomedical applications, hydrogels expand or contract in response to moisture or temperature changes.

- Liquid crystal elastomers (LCEs): Materials that can undergo complex deformations based on external stimuli like heat or electric fields.

- Composite materials: These combine different elements to enhance their responsiveness and durability.

The ability to pre-program transformations at the molecular level means that 4D printing technology can produce structures that dynamically adjust to their environment. For instance, self-folding origami structures, moisture-responsive textiles, and self-repairing surfaces all demonstrate the versatility of smart materials in 4D printing.

As research progresses, we can expect even more advanced applications of 4D printing in aerospace, robotics, and regenerative medicine, further pushing the boundaries of what’s possible in manufacturing and material science.

When Was 4D Printing Invented?

The concept of 4D printing was first introduced in 2013 by Skylar Tibbits, a researcher at the Massachusetts Institute of Technology (MIT). Tibbits, the founder of the Self-Assembly Lab at MIT, unveiled the idea during a TED Talk, where he demonstrated how programmable materials could transform over time in response to external stimuli such as heat, water, or light. This groundbreaking innovation expanded upon traditional 3D printing by incorporating time as the fourth dimension, allowing printed objects to change their shape, properties, or functionality after fabrication.

While 3D printing had already revolutionized manufacturing by enabling precise, customizable, and rapid prototyping, 4D printing introduced a dynamic element—materials that could self-assemble, fold, or adapt to environmental changes. This advancement was made possible through a combination of smart materials like shape-memory polymers (SMPs) and hydrogels, alongside computational design techniques that dictated how these materials would respond over time.

Following Tibbits’ introduction, research in 4D printing technology gained momentum, with collaborations between MIT, Harvard University, and major corporations exploring applications in fields like biomedicine, aerospace, and construction. As scientists continue to refine 4D printing materials and techniques, this technology is paving the way for self-healing structures, adaptive textiles, and futuristic innovations across multiple industries.

Key Applications of 4D Printing

Biomedical Engineering

One of the most promising applications of 4D printing technology is in the medical field. Researchers are developing smart materials in 4D printing that can create self-folding stents, shape-changing drug delivery systems, and patient-specific implants that adjust to physiological conditions. Hydrogels, for instance, have been engineered to expand or contract based on body temperature, improving targeted medication delivery.

Construction and Architecture

The construction industry can benefit from 4D printing technology by creating self-assembling structures that reduce the need for extensive manual labor. Smart building materials can respond to environmental conditions such as temperature and humidity, improving energy efficiency. For example, moisture-responsive façades could automatically adjust to optimize ventilation and insulation in buildings.

Aerospace and Automotive Sectors

4D printing holds great potential in designing adaptive components for aircraft and vehicles. Shape-memory materials can be used to develop lightweight, self-healing structures that respond to external stress. This could lead to more resilient aircraft wings or car bodies that can restore minor damage without requiring repairs.

Clothing and Textiles

The fashion industry is exploring smart materials in 4D printing to create garments that adapt to environmental conditions. Clothing that adjusts based on temperature, humidity, or movement could provide greater comfort and functionality. Self-healing fabrics could also increase the durability of textiles.

Soft Robotics

Soft robotics is another emerging field where 4D printing technology can make a significant impact. Unlike traditional rigid robots, 4D-printed soft robots can change shape and function dynamically. This flexibility allows for safer human-robot interaction, particularly in healthcare and industrial automation.

Challenges and Future Developments

Challenges Facing 4D Printing Technology

While the potential of 4D printing technology is immense, several obstacles must be overcome:

- Material Limitations: The development of highly responsive, durable, and scalable smart materials in 4D printing remains a challenge.

- Manufacturing Precision: Ensuring consistent transformations in 4D-printed objects requires precise control over material properties and environmental conditions.

- High Costs: The current costs associated with 4D printing technology and smart materials limit widespread adoption in commercial applications.

Future Developments

Despite these challenges, ongoing research is pushing 4D printing technology forward:

- Advanced Smart Materials: Scientists are developing new programmable materials with improved responsiveness and durability.

- Integration with AI and IoT: Combining 4D printing technology with artificial intelligence and IoT sensors could lead to self-learning, autonomous systems.

- Scalability and Commercialization: As production techniques improve, 4D printing technology is expected to become more accessible and widely used across industries.

4D Printing in Construction: Revolutionizing the Industry

4D printing is transforming the construction industry by enabling self-healing materials, adaptive structures, and sustainable innovations. Unlike traditional construction materials that degrade over time, 4D printing in construction introduces materials that can respond dynamically to environmental conditions, reducing maintenance costs and increasing structural longevity.

Real-World Applications

- Self-repairing concrete: Scientists are developing concrete infused with smart polymers that expand and contract to seal cracks automatically, extending the lifespan of buildings and infrastructure.

- Shape-shifting materials: Buildings made with self-assembling materials can adjust to environmental conditions such as humidity, temperature, and seismic activity, enhancing resilience.

- Sustainable, biodegradable structures: Researchers are exploring eco-friendly smart materials that degrade safely over time or adapt to specific environmental needs.

Challenges Compared to Traditional Construction

While 4D printing in construction presents numerous advantages, scalability remains a major challenge. The high cost of smart materials in 4D printing, along with the need for specialized design and programming, makes large-scale implementation difficult. However, as research advances, these limitations may be overcome, paving the way for applications of 4D printing in commercial and residential building projects.

Challenges & Limitations of 4D Printing

Despite its potential, the 4D printing process faces several hurdles before achieving widespread adoption.

Key Challenges

- High Production Costs: The materials and fabrication techniques required for smart materials in 4D printing are expensive, making mass production difficult.

- Complex Transformations: Predicting and controlling material behavior over time remains a challenge, especially for real-world applications.

- Durability & Scalability: Many self-assembling materials degrade quickly, requiring further research to improve long-term stability.

Future Prospects: Where Is 4D Printing Headed?

The future of 4D printing technology is poised to revolutionize multiple industries, including healthcare, aerospace, and environmental sustainability. As researchers continue to explore new applications, this transformative technology will likely reshape how materials and products interact with their surroundings.

4D Printing in Healthcare

One of the most promising applications of 4D printing technology is in healthcare. Scientists are developing bioprinting techniques that use programmable materials to create adaptive implants and prosthetics. Future advancements may allow for self-healing medical devices that can repair themselves inside the body, reducing the need for multiple surgeries. Additionally, applications of 4D printing in drug delivery systems could enable medicines to release their active ingredients in response to specific physiological conditions.

4D Printing in Aerospace and Space Exploration

In aerospace, 4D printing technology is being explored to create shape-changing aircraft components, self-repairing spacecraft materials, and adaptable satellite structures. NASA and other space agencies are investigating how 4D-printed structures could respond to extreme space conditions, ensuring durability and efficiency in long-term space missions. This technology could lead to the development of deployable habitats on Mars or self-assembling space stations.

4D Printing for Environmental Sustainability

The applications of 4D printing extend to sustainability, offering solutions for eco-friendly materials and waste reduction. Scientists are developing biodegradable smart materials that adjust to environmental factors and decompose naturally at the end of their lifecycle. In the construction industry, self-healing concrete and shape-shifting building materials could significantly reduce maintenance costs and resource consumption.

As research in 4D printing technology progresses, we can expect its integration into mainstream manufacturing, reducing waste, optimizing energy use, and enhancing product longevity. Future innovations may bring fully autonomous structures and self-repairing materials into everyday applications.

Conclusion: The Impact of 4D Printing on the Future

4D printing represents a significant evolution in additive manufacturing, offering dynamic solutions that can transform industries ranging from healthcare to aerospace. By leveraging smart materials in 4D printing, researchers and engineers are developing innovative applications that push the boundaries of material science and automation.

While challenges such as material limitations and cost barriers remain, ongoing advancements in 4D printing technology promise a future where self-adapting structures, shape-changing implants, and self-healing materials become a reality. As research progresses, this transformative technology will likely become an integral part of modern industry and innovation.

For those interested in learning more about related advancements, consider exploring:

- The Future of Bioprinting: 3D Printing Human Organs

- Self-Healing Concrete: The Next Step in Sustainable Engineering

- Superhydrophobic Materials: Innovations for a Sustainable Future

- Geopolymer Concrete- Revolutionizing Construction

As 4D printing technology continues to evolve, staying informed about new developments will be essential for researchers, engineers, and industry leaders looking to harness the full potential of this groundbreaking innovation.