3D-Printed Heart: Beating Hearts Printed to Order

Imagine a future where this desperate wait becomes a thing of the past. What if, instead of relying on the generosity of a deceased donor with a compatible organ, patients could receive a custom-made heart, bio-printed using their cells? This isn’t science fiction – it’s the cutting-edge frontier of 3D printing technology, and it has the potential to revolutionize the field of organ transplantation.

Every minute, someone in the United States is added to the waiting list for a life-saving organ transplant. The stark reality is, that donor organs are scarce. In 2023 alone, over 106,000 people in the US awaited a lifesaving organ transplant, according to the United Network for Organ Sharing (UNOS). Tragically, around 22 people die each day waiting for an organ that never comes.

This blog post dives into the exciting world of 3D-printed hearts, exploring the technology behind it, the groundbreaking research currently underway, and the immense potential it holds for saving countless lives. We’ll also discuss the challenges that need to be overcome before 3D-printed hearts become a mainstream medical reality. So, buckle up and prepare to explore the future of medicine, where hearts can be printed to order, offering hope to millions waiting for a second chance at life.

Before we delve into the fascinating world of 3D-printed hearts, let’s gain a solid understanding of the foundational technology

What Is 3D Printing

3D printing, also known as additive manufacturing. Unlike traditional subtractive manufacturing techniques that carve away material to create a desired shape, 3D printing takes a revolutionary approach: building objects layer by layer. Imagine constructing a building not with bricks and mortar, but by meticulously adding tiny slices one on top of another – that’s the essence of 3D printing.

Here’s a closer look at the 3D printing process, which can be broken down into four key stages:

Digital Design: The Blueprint of Creation

The journey begins with a digital model. Using sophisticated computer-aided design (CAD) software, designers meticulously create a virtual 3D representation of the object they want to print. This digital blueprint acts as the instruction manual for the 3D printer, dictating the precise shape, size, and internal features of the final product.

Material Selection: Choosing the Right Building Blocks

The choice of material for 3D printing depends heavily on the intended use of the final object. In the medical field, biocompatible materials are paramount. These specially formulated materials are chosen for their ability to interact safely with the human body, minimizing the risk of rejection or complications. Imagine using a specialized ink made from living cells and biocompatible substances – that’s the essence of bioprinting, a crucial aspect of creating 3D-printed hearts.

Guide for material selection in 3D-Printing

Printing: Bringing the Design to Life

Once the digital model and material are selected, it’s time for the magic to happen! The 3D printer takes center stage, meticulously translating the digital instructions into a physical object. The printer reads the 3D model layer by layer and deposits the chosen material, building the object from the bottom up. This process can be akin to a tiny inkjet printer meticulously laying down material instead of ink. The printing process takes time anywhere from a few minutes to days, depending on the complexity of the design.

Post-Processing: The Finishing Touches

Freshly printed objects may sometimes require additional processing steps to achieve their final form. This could involve support removal (structures used during printing to maintain stability), heat treatment to enhance material properties, or surface finishing for a smoother aesthetic. In the context of bioprinting, post-processing might involve nurturing the printed tissue in a bioreactor, a controlled environment that mimics the conditions within the human body, allowing the cells to mature and develop into functional tissue.

The Application of 3D Printing: Beyond Imagination

The impact of 3D printing goes far beyond creating trinkets and figurines. This transformative technology has revolutionized numerous industries, from aerospace and automotive to fashion and dentistry. Here’s a glimpse into some of its current applications:

Medicine:

Prosthetics: Customized prosthetic limbs can be 3D printed to perfectly fit an individual’s needs, improving comfort, functionality, and quality of life for amputees.

Dental Implants: Complex dental implants can be 3D printed using biocompatible materials, offering a more precise and personalized approach to dental restoration.

Surgical Models: 3D-printed models of organs or bones can be created from medical scans, allowing surgeons to practice complex procedures beforehand and improve surgical outcomes.

Aerospace: Lighter and stronger aircraft parts can be 3D printed, leading to more fuel-efficient airplanes.

Automotive: Customized car parts and prototypes can be 3D printed for rapid design iteration and testing in the automotive industry.

Consumer Goods: The possibilities are vast, from customized phone cases and jewelry to functional household items like lamps and utensils.

Fashion: 3D printing has opened doors for creating innovative and intricate clothing designs, pushing the boundaries of fashion.

3D printed hearts represent the cutting edge of this technology, with the potential to transform the landscape of organ transplantation and offer hope to millions of patients worldwide. As research and development progress, we can expect even more innovative applications of 3D printing to emerge, shaping the future across various industries.

Imagine a world where a failing heart doesn’t equate to a death sentence. A world where patients in desperate need don’t languish on waiting lists, yearning for a compatible donor organ. This isn’t a utopian fantasy; it’s the very real promise that 3D-printed hearts hold. Here’s how this groundbreaking technology has the potential to revolutionize organ transplantation and usher in a new era of hope for millions:

The potential of 3D Printing

Eradicating the Organ Shortage: A Gift of Time

The current landscape of organ transplantation is marred by a stark reality – a cruel disparity between the number of patients desperately in need and the availability of suitable donor organs. In the United States alone, over 106,000 individuals currently wait for a life-saving heart transplant, according to the United Network for Organ Sharing (UNOS). Tragically, around 22 people die each day waiting for an organ that never arrives.

3D-printed hearts offer a glimmer of hope in this bleak scenario. By creating functional hearts using a patient’s own cells, the technology bypasses the need for a donor altogether. This eliminates the agonizing wait times, offering a precious gift of time – the most valuable commodity for patients battling heart failure.

The Power of Personalization: A Heart Made Just for You

Unlike donor hearts, which are one-size-fits-all, 3D-printed hearts can be meticulously tailored to the unique needs of each patient. Using medical imaging techniques, doctors can create a digital replica of the patient’s own heart, incorporating its specific size, shape, and anatomical features. This level of personalization can lead to significantly improved transplant outcomes. A perfectly fitting heart translates to better blood flow, reduced risk of complications, and a faster recovery for the patient.

Minimizing Rejection: A Body That Recognizes Its Own

One of the biggest challenges associated with traditional transplants is the risk of organ rejection. The body’s immune system recognizes the donor heart as foreign and attacks it, leading to potentially life-threatening complications. 3D-printed hearts hold the potential to revolutionize this aspect of transplantation. Because these hearts are created using the patient’s own cells, the immune system won’t perceive them as a foreign invader. This significantly reduces the risk of rejection, offering a smoother path to recovery and a better long-term prognosis for the patient.

A Boon for Research: A Platform for Innovation

Beyond offering hope for transplant patients, 3D-printed hearts can serve as invaluable tools for medical research. Scientists can use these intricate bio-printed models to study heart disease progression, test the efficacy of new drugs, and explore innovative treatment options in ways that were previously impossible. Imagine being able to simulate different heart conditions and test potential therapies on a bioprinted replica, accelerating the development of life-saving treatments.

The promise of 3D-printed hearts extends far beyond the realm of science fiction. It represents a tangible hope for a future where heart failure doesn’t equate to a death sentence, but rather a treatable condition.

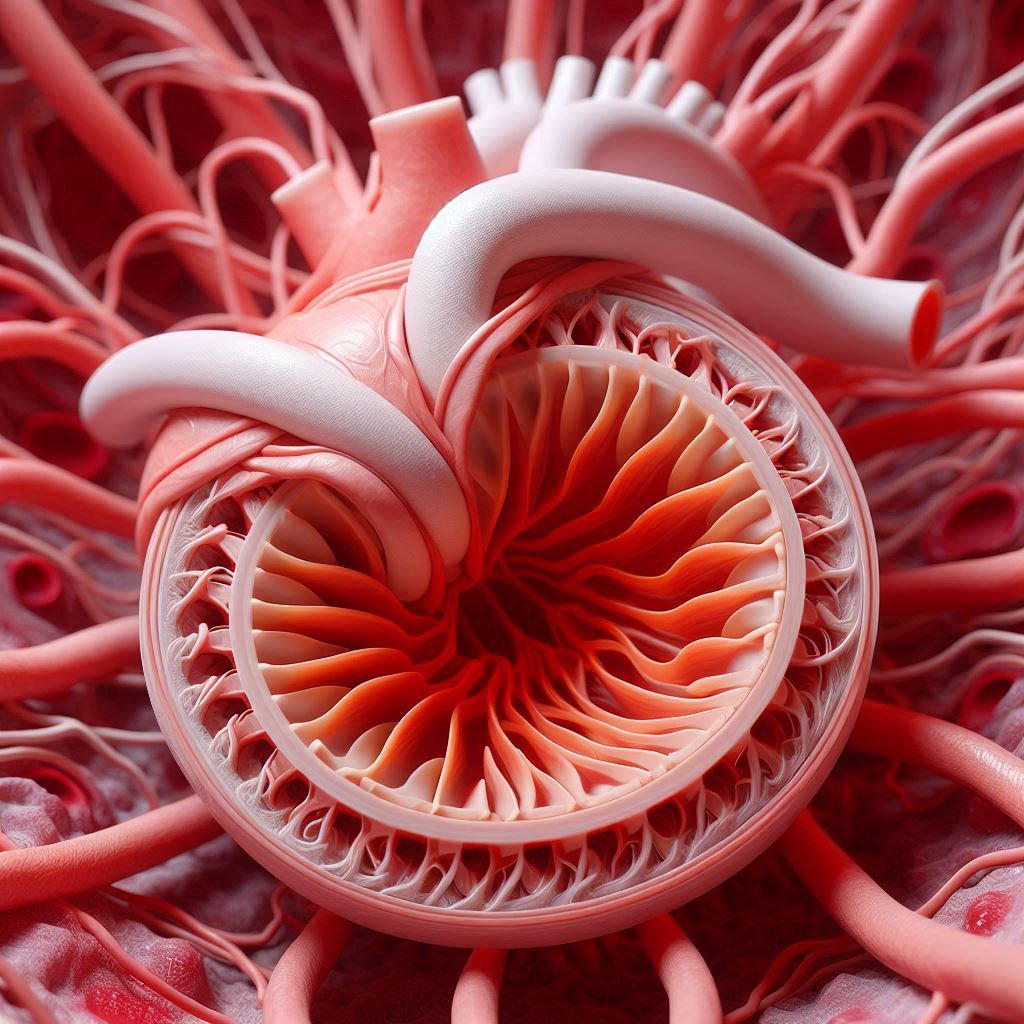

3D-Printed Heart Valves: A Beating Revolution on the Horizon

For decades, the waitlist for a life-saving heart valve transplant has been a cruel reality for countless patients. Traditional options, while effective, come with limitations. But on the cusp of a medical revolution lies the promise of 3D-printed heart valves, offering a potential solution that’s personalized, precise, and brimming with hope.

Breakthrough #1: Bio-inks Evolving into Living, Beating Replacements

One of the most exciting advancements is the development of next-generation bio-inks. These specialized materials act as the “ink” in 3D printing, and recent breakthroughs have yielded bio-inks with superior properties. Researchers are creating bio-inks that are not only biocompatible but also possess exceptional strength and flexibility. This mimics the natural tissue of a heart valve, ensuring the printed valve can withstand the demanding environment within the human body. Imagine a bio-ink that combines the elasticity of human tissue with the durability of cutting-edge materials – that’s the future of bio-inks for 3D-printed heart valves.

Breakthrough #2: You, the Designer: Personalized Valves for a Perfect Fit

The beauty of 3D printing lies in its ability to create intricate objects based on digital models. This opens doors for patient-specific heart valve design. Using advanced medical scans, doctors can create a virtual replica of a patient’s heart and design a 3D-printed valve that perfectly fits their unique anatomy. This level of customization can lead to improved valve function and potentially minimize complications post-surgery. Additionally, researchers are exploring the possibility of incorporating a patient’s own stem cells into the bio-ink. These stem cells could then grow into living heart valve tissue, further reducing the risk of rejection.

How It Works

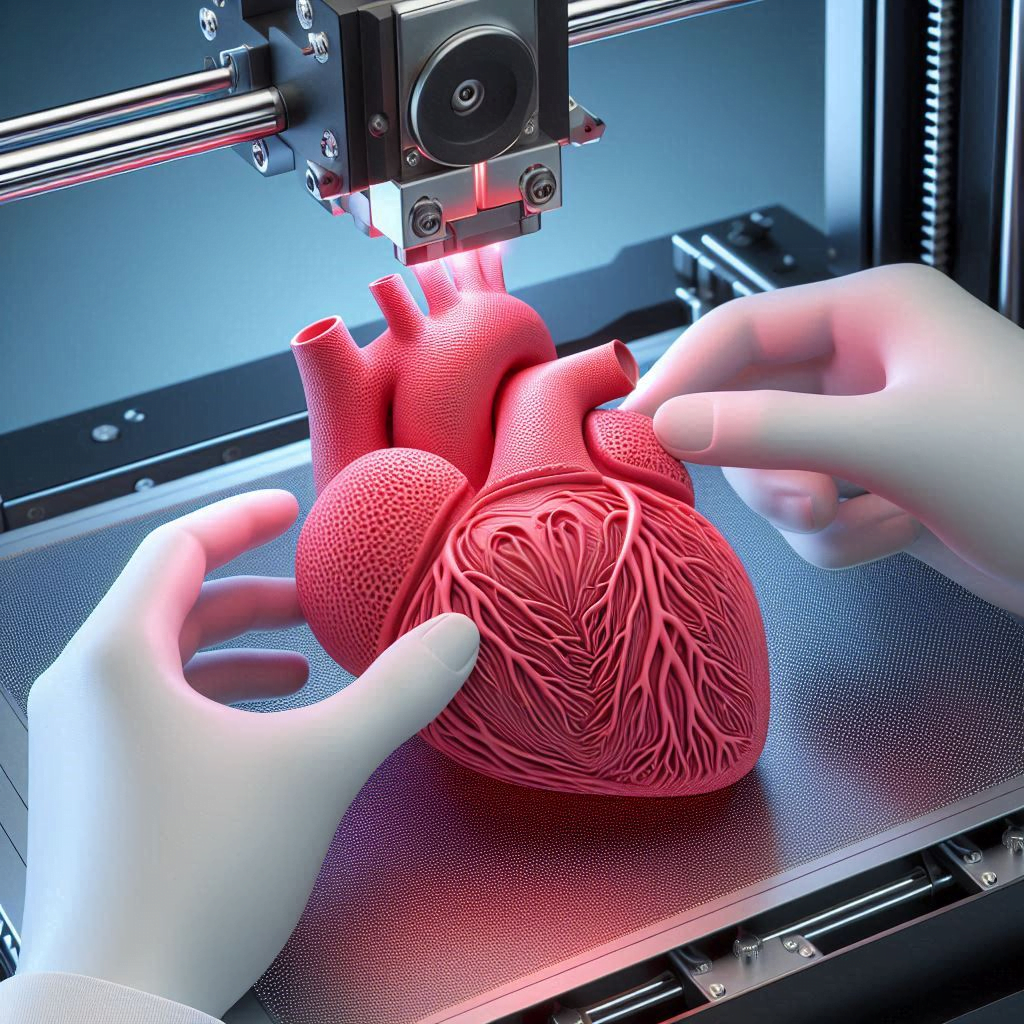

The human body is an intricate marvel, and the heart, its tireless engine, is no exception. 3D printing technology is poised to revolutionize the field of heart transplantation by offering the potential to create custom-made hearts using a patient’s own cells. But how exactly does this process work? Let’s delve into the fascinating steps that bring a 3D-printed heart to life:

Mapping the Blueprint: Bioimaging

The journey begins with a detailed map of the patient’s heart. Sophisticated imaging techniques like magnetic resonance imaging (MRI) and computed tomography (CT) scans come into play. These scans capture a wealth of data, revealing the heart’s intricate structure, including its chambers, valves, and blood vessels, in stunning detail. This information serves as the crucial blueprint for the 3D model that will guide the printing process.

The Ink of Life: Biomaterials

Traditional 3D printers rely on plastic or metal filaments. However, 3D-printed hearts necessitate a special kind of “ink” – bio-ink. This biocompatible concoction is a marvel of bioengineering, combining living cells harvested from the patient and biocompatible substances that can support cell growth and function. Imagine a specialized ink cartridge filled not with ink, but with a cellular soup teeming with life! The chosen cells can vary depending on the specific needs of the heart, potentially including heart muscle cells (cardiomyocytes), endothelial cells (lining the blood vessels), and other specialized cell types that work together to orchestrate the heart’s rhythmic contractions.

Printing with Precision: The 3D Printing Process

With the blueprint in hand and the bio-ink loaded, it’s time for the magic of 3D printing to unfold. A specialized 3D printer, equipped with sophisticated nozzles, takes center stage. Unlike a typical 3D printer that lays down plastic in layers, this printer meticulously deposits the bio-ink layer by layer, guided by the digital model derived from the bioimaging data. Each layer carefully builds upon the previous one, gradually bringing the 3D model of the heart to life. The printing process can be quite intricate, taking anywhere from several hours to days depending on the complexity and size of the heart being printed.

From Print to Living Tissue: Cultivation

Freshly printed hearts might resemble intricate scaffolds rather than fully functional organs. To bridge this gap, the printed heart is placed in a special chamber called a bioreactor. This controlled environment mimics the conditions within the human body, providing the necessary nutrients and signals to coax the cells within the bio-ink to mature and organize themselves. Imagine a nurturing incubator specifically designed to cultivate the printed heart tissue! Over time, with careful monitoring and adjustments within the bioreactor, the cells begin to develop into functional cardiac tissue, replicating the natural structure and function of a healthy heart.

The Gift of Life: Transplantation

The culmination of this intricate process is a moment of immense hope – the 3D-printed heart is ready for transplantation. After undergoing rigorous testing to ensure its viability and functionality, the heart can be transplanted into the patient. Because the heart is made from the patient’s own cells, the risk of immune rejection, a major hurdle in traditional transplants, is significantly minimized. This personalized approach to organ transplantation holds immense potential for improved patient outcomes and a faster recovery process.

Current Advances and Challenges

Scaling the Peaks: Advances in Technology

Researchers are making significant strides in overcoming the technical obstacles associated with 3D-printed hearts. Here are some key areas of progress:

Vascularization: The Lifeline Network – One of the biggest challenges is creating a network of blood vessels (vascularization) within the printed heart. These intricate channels are essential for delivering oxygen and nutrients to all the cells, ensuring the heart’s proper function. Advancements in bioprinting technology are constantly improving, with researchers developing techniques to incorporate delicate vascular networks within the printed tissue. Imagine printing not just the heart structure, but also a built-in circulatory system!

Cellular Vitality: Keeping the Cells Alive and Kicking – Ensuring that the cells used in bio-ink remain viable and functionally active throughout the printing process and post-transplantation is critical. Researchers are exploring various strategies to enhance cell survival rates and functionality. This might involve optimizing the bio-ink composition, developing techniques to minimize stress on cells during printing, and identifying growth factors that promote healthy cell activity within the printed tissue.

Navigating the Regulatory Maze: Ensuring Safety and Efficacy

As with any groundbreaking medical technology, 3D-printed organs must undergo rigorous testing and secure regulatory approval before widespread use. This process is essential to ensure the safety and efficacy of these organs for human transplantation. Regulatory bodies need to establish clear guidelines and frameworks for testing and evaluation, while researchers strive to develop standardized protocols for bioprinting hearts. Collaboration between scientists, regulatory agencies, and medical professionals is crucial in navigating this complex landscape.

A Glimpse of the Future: Milestones on the Journey

In 2019, scientists at Tel Aviv University successfully 3D printed a small-scale heart using human tissue. While not yet suitable for human transplantation, this milestone serves as a powerful testament to the feasibility of the technology. It demonstrates the ability to create complex heart structures using bioprinting techniques, paving the way for further advancements.

United Minds for a Beating Future: The Power of Collaboration

The road to functional 3D-printed hearts necessitates a global village approach. Here’s a glimpse into the collaborative landscape:

Tel Aviv University (Israel): In 2019, researchers at Tel Aviv University made a significant breakthrough by successfully 3D printing a miniaturized human heart complete with blood vessels and ventricles. This achievement serves as a springboard for further research and development.

World’s first bio-printed heart

Wyss Institute at Harvard University (USA): This prestigious institute is a hub for researchers exploring bioprinting techniques using bio-inks derived from a patient’s own cells. Their focus on creating intricate vascular networks within the printed tissues is crucial for ensuring a functional heart.

Mayo Clinic (USA): The Mayo Clinic is actively involved in research on bioprinting heart valves and other cardiac tissues. Their goal is to improve outcomes for patients with heart valve disease by creating personalized replacements using bioprinting technology.

MIT engineers (USA): MIT engineers are making significant contributions by developing functional replicas of a patient’s heart, including the right ventricle, capable of mimicking blood-pumping action. These replicas can be used for pre-surgical planning and testing different treatment approaches for individual patients.

These are just a few examples of the collaborative efforts propelling the field forward. As researchers, engineers, medical professionals, and bioethicists from around the world come together, the potential for even more groundbreaking advancements is immense.

Challenges in the development of 3D-printed heart

Addressing the Ethical Gray Areas: Open Dialogue for a Transparent Future

As with any pioneering technology, ethical considerations require thoughtful discussion:

Patient Consent: How will informed consent be obtained for using a patient’s cells in 3D printing organs? Open communication and clear guidelines are essential to ensure patient autonomy and trust.

Intellectual Property: Who will own the intellectual property rights to the technology and the printed organs? Finding a balance that fosters innovation while ensuring equitable access to this life-saving technology is crucial.

Accessibility and Equity: How will the cost of 3D-printed organs be managed to ensure that everyone in need has access to this potentially life-saving treatment? Addressing affordability concerns is paramount to prevent further disparities in healthcare.

By fostering open dialogue and proactively addressing these issues, the medical community can ensure that 3D-printed hearts become a beacon of hope for all, not just the privileged few.

A New Dawn for Organ Transplantation: Beyond the Waiting List

Imagine a future where: Wait times are slashed: Patients in desperate need of heart transplants wouldn’t have to endure years on waiting lists, clinging to the hope of a compatible donor. 3D printed hearts, created using their cells, could significantly reduce wait times, offering a precious gift – time.

Personalized medicine becomes a reality: Custom-made hearts can be meticulously tailored to fit the patient’s unique anatomy and physiology, potentially leading to improved transplant outcomes and faster recovery times.

Rejection risks plummet: Using a patient’s own cells for the printed heart can significantly minimize the risk of immune rejection, a major hurdle in traditional transplants. This could lead to a smoother post-operative journey for patients.

Beyond Hearts: A Ripple Effect of Hope

The success of 3D-printed hearts could have a ripple effect, paving the way for printing other vital organs:

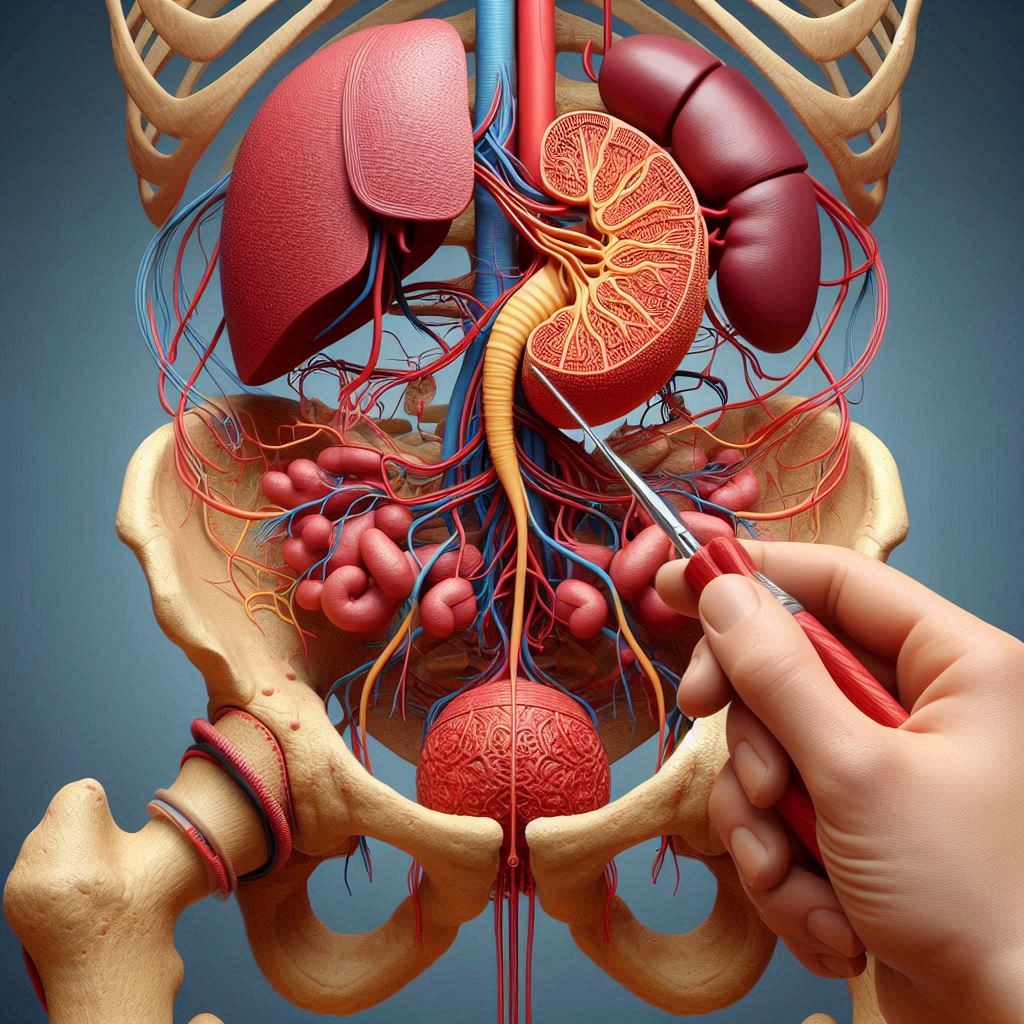

Kidneys: Patients suffering from kidney failure could benefit from bio-printed kidneys, eliminating the need for dialysis and offering a renewed lease on life.

Livers: The potential to bioprint livers could offer hope to those battling liver diseases, potentially reducing wait times and improving transplant outcomes.

Lungs: bio-printed lungs could provide a glimmer of hope for patients with chronic lung diseases, offering a new chance to breathe freely.

The future of 3D-printed organs holds immense potential to revolutionize the field of medicine. As research and development continue, we can move closer to a world where organ failure doesn’t equate to a death sentence, but rather a treatable condition. With continued collaboration, ethical considerations addressed, and technological advancements, 3D-printed hearts and other organs have the potential to transform the landscape of medicine, offering a future brimming with hope for millions of patients worldwide.

Conclusion

3D-printed hearts represent a groundbreaking intersection of technology and medicine. While challenges remain, the rapid advancements in this field offer a glimpse into a future where organ shortages are a thing of the past. As research continues to evolve, we move closer to a world where the marvel of a 3D-printed heart beating inside a patient is not just a dream, but a life-saving reality. The journey will require continued investment, collaboration, and careful consideration of ethical implications. However, the potential benefits of 3D-printed hearts are undeniable, offering hope for millions of patients waiting for a second chance at life.

Planning your next adventure? Don’t forget to check out my other blog post