Introduction

Concrete is the most widely used construction material in the world, valued for its durability and strength. However, traditional concrete is prone to cracking, which compromises structural integrity and leads to costly repairs. Enter self-healing concrete, an innovative material designed to repair its own cracks autonomously. This breakthrough technology not only extends the lifespan of structures but also reduces maintenance costs and contributes to sustainable construction practices. Discover what self-healing concrete is and how it works, including bacterial concrete and Basilisk innovations for future construction.

What is Self-Healing Concrete?

Self-healing concrete is a type of concrete that has the ability to repair its own cracks without human intervention. The concept mimics natural healing processes, like how human skin repairs itself after a cut. This type of concrete is designed to extend the lifespan of structures by automatically filling in cracks as they form, thereby maintaining the material’s integrity and strength over time.

Traditional concrete tends to crack due to a variety of reasons, such as thermal expansion, shrinkage, and mechanical stress. These cracks, if left unchecked, can lead to significant structural damage, water infiltration, and corrosion of reinforcement bars, all of which compromise the safety and durability of the structure. Self-healing concrete addresses these issues by incorporating materials that react to crack formation and autonomously seal them, thereby preventing further deterioration.

Types of Self-Healing Concrete and Their Mechanisms

Self-healing concrete comes in various types, each employing a unique mechanism to repair cracks autonomously. These mechanisms leverage biological, chemical, or mechanical processes to restore the material’s integrity without human intervention. Let’s delve deeper into the three primary types of self-healing concrete:

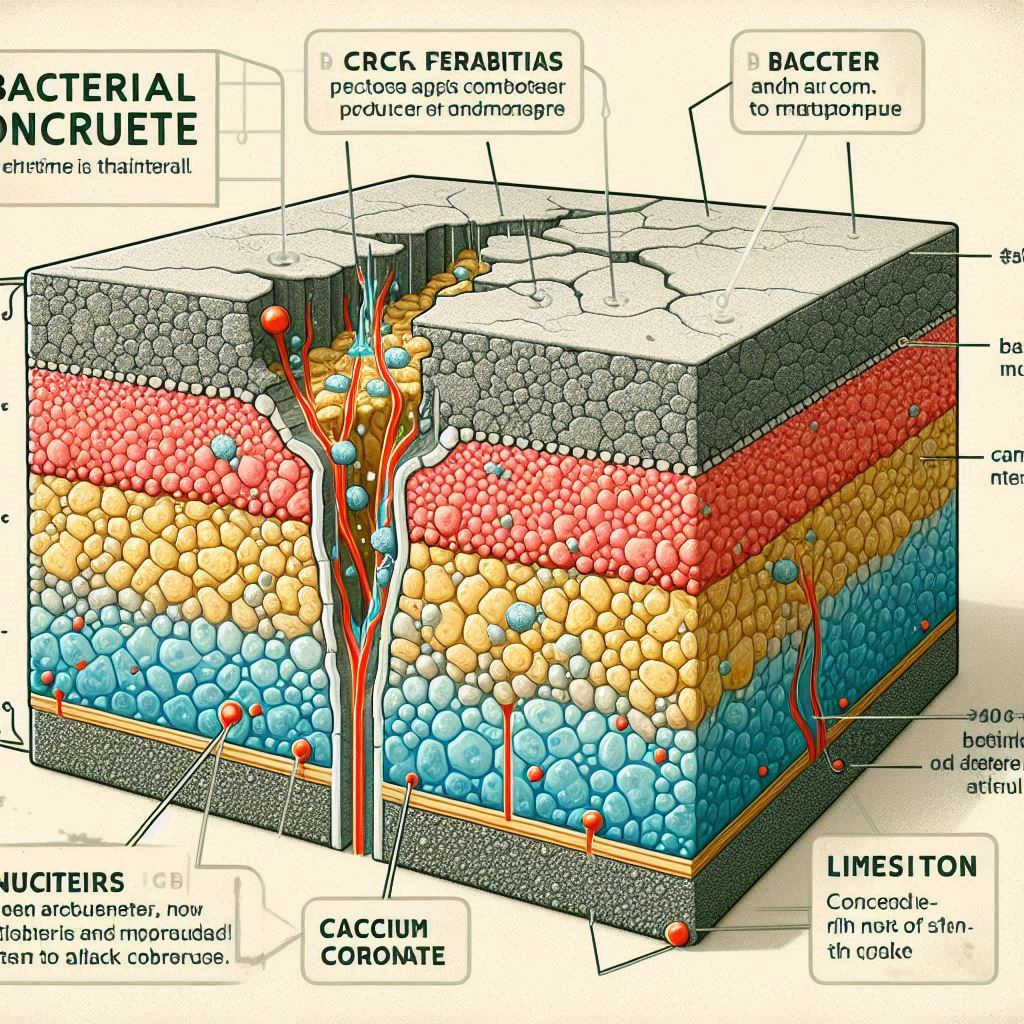

Bacterial Concrete

Bacterial concrete, also known as bio-concrete, leverages the natural processes of bacteria to heal cracks in the concrete. The bacteria most commonly used in self-healing concrete are species of the Bacillus genus, such as Bacillus megaterium, Bacillus sphaericus, and Bacillus pasteurii. These bacteria are chosen because they can survive the harsh, alkaline environment of concrete and remain dormant for extended periods.

Mechanism of Action:

- Dormancy and Activation: The bacteria are embedded in the concrete in a dormant state, along with a nutrient source like calcium lactate. When cracks form in the concrete, they create pathways that allow water and oxygen to enter. The presence of water and oxygen is the trigger that activates the dormant bacteria.

- Metabolic Process: Once activated, the bacteria begin to feed on the calcium lactate and convert it into calcium carbonate (limestone) through their metabolic processes. This transformation is crucial because calcium carbonate is a primary component of natural limestone, which has excellent adhesive properties and compatibility with concrete.

- Crack Sealing: The produced limestone fills the cracks in the concrete. Over time, the continuous production of calcium carbonate leads to the sealing of the cracks, restoring the concrete’s structural integrity and preventing further water ingress, which could cause additional damage or corrosion to steel reinforcements.

- Environmental Suitability: Bacterial concrete is particularly effective in environments where concrete structures are frequently exposed to moisture, such as marine environments, underwater structures, basements, tunnels, and bridges. The constant presence of water ensures the bacteria are periodically activated, providing ongoing self-healing capabilities.

Advantages and Innovations:

- Longevity: The bacteria used in self-healing concrete can remain dormant for decades, allowing for multiple cycles of healing over the lifespan of the structure. This feature makes it particularly valuable for structures with limited access for maintenance.

- Eco-Friendliness: By reducing the need for repairs and maintenance, bacterial concrete minimizes the use of additional resources and reduces the carbon footprint associated with concrete production and repair.

- Research and Development: New research is exploring genetically modified bacteria to enhance the efficiency and effectiveness of self-healing processes, potentially enabling faster repair and improved structural outcomes.

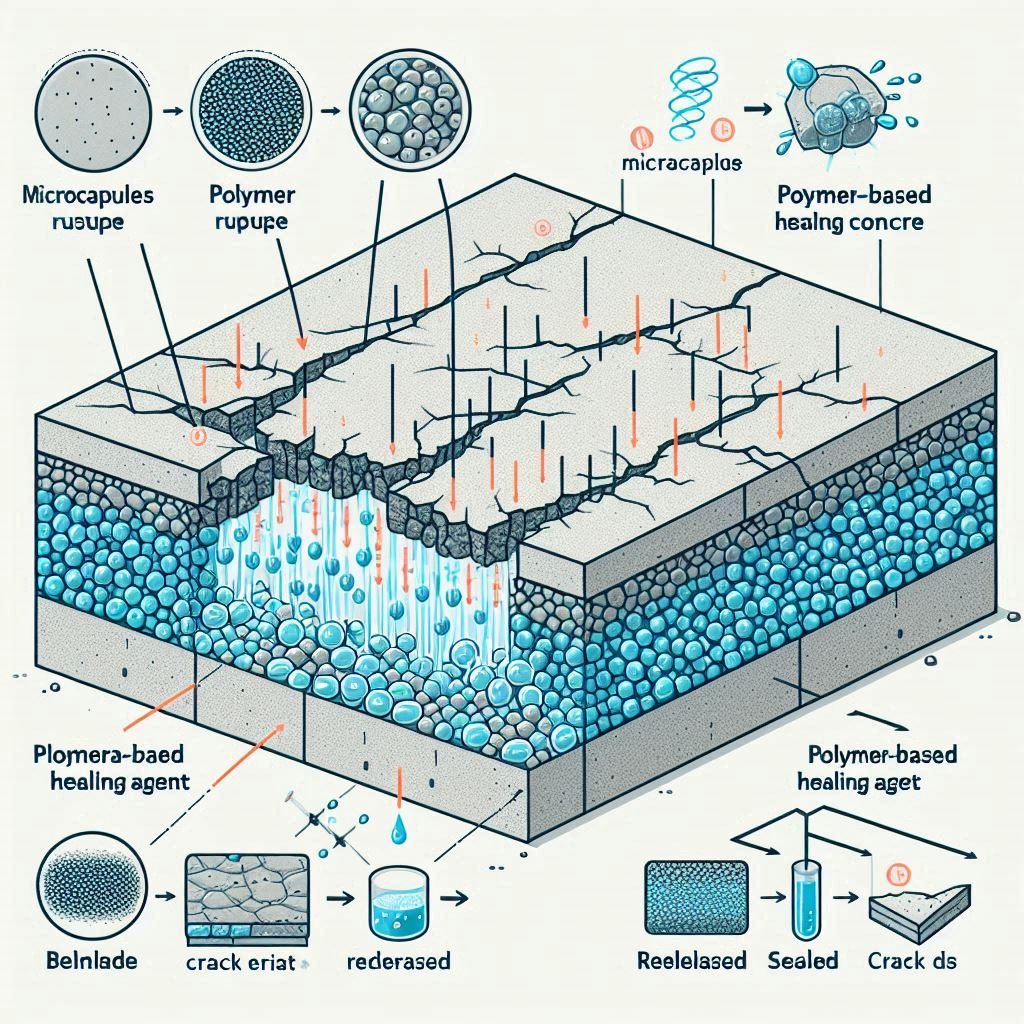

Polymer-Based Self-Healing Concrete

Polymer-based self-healing concrete involves the incorporation of microcapsules filled with liquid polymeric healing agents, such as epoxy resins or polyurethane, into the concrete matrix. These polymers are chosen for their excellent adhesion properties, flexibility, and durability once cured.

Mechanism of Action:

- Microcapsule Incorporation: During the mixing process, microcapsules containing the polymeric healing agents are evenly distributed throughout the concrete. These microcapsules are designed to remain intact until the concrete experiences stress and cracks.

- Crack Formation and Microcapsule Rupture: When a crack forms in the concrete, the stress causes the microcapsules located at the crack’s path to rupture. This rupture releases the healing agent directly into the crack.

- Polymerization and Crack Sealing: Upon release, the liquid polymer flows into the crack and undergoes a chemical reaction (polymerization) in the presence of a catalyst embedded in the concrete matrix or exposed by the crack itself. This reaction hardens the polymer, effectively sealing the crack and preventing further water ingress and structural damage.

- Durability and Flexibility: The hardened polymer not only seals the crack but also adds a degree of flexibility to the repaired area, which can help absorb further stress and reduce the likelihood of new cracks forming nearby.

Advantages and Innovations:

- Rapid Response: The healing process is initiated immediately upon crack formation, allowing for a rapid response to damage and minimizing the risk of larger structural issues.

- High Compatibility: The polymer-based approach is compatible with various types of concrete, making it suitable for a wide range of applications, from high-rise buildings to industrial floors.

- Advanced Formulations: Recent innovations include the development of self-healing polymers that can heal multiple times, further extending the lifespan of concrete structures and reducing maintenance costs.

Capsule-Based Self-Healing Concrete

Capsule-based self-healing concrete is a versatile approach that involves embedding a wide range of healing agents within microcapsules or a vascular network system within the concrete matrix. These capsules can contain mineral compounds, sodium silicate, adhesives, or other chemical agents designed to activate upon crack formation.

Mechanism of Action:

- Diverse Healing Agents: The capsules can be filled with various healing agents, depending on the specific requirements of the project and environmental conditions. Common agents include sodium silicate (a water glass that forms a gel upon contact with water) and mineral-based compounds that react chemically to form a solid seal.

- Trigger and Release: Similar to polymer-based systems, when cracks form, they trigger the rupture of the capsules embedded within the concrete. This rupture releases the healing agent directly into the cracks, where it can react with moisture or other environmental triggers to form a solid, impermeable material.

- Chemical Reactions and Crack Sealing: The released agents undergo a chemical reaction upon contact with environmental elements such as water or carbon dioxide. For example, sodium silicate reacts with calcium hydroxide, a byproduct of concrete hydration, to form a calcium silicate hydrate gel. This gel fills and seals the cracks, providing a robust barrier against water and air infiltration.

- Tailored Healing Responses: Capsule-based systems can be tailored to the specific environmental conditions and mechanical stresses of the application. For instance, different types of capsules can be combined in a single concrete mix to provide a multi-tiered healing response suitable for diverse conditions, such as freeze-thaw cycles or seismic activity.

Advantages and Innovations:

- Versatility: Capsule-based self-healing concrete is highly adaptable, making it suitable for a wide range of construction projects, from residential buildings to infrastructure in earthquake-prone areas.

- Customizability: The use of different healing agents allows for customized healing properties that can be adjusted based on the expected type and frequency of cracking, environmental exposure, and specific structural needs.

- Multi-functional Systems: Researchers are exploring the use of multi-functional capsules that can perform additional functions, such as monitoring the structural health of the concrete or providing additional thermal insulation.

Summary of Types and Their Applications

Each type of self-healing concrete offers unique advantages and is suitable for specific applications based on the expected environmental conditions, mechanical stresses, and desired longevity. Bacterial concrete is ideal for marine environments and structures with limited access. Polymer-based self-healing concrete is well-suited for dynamic, high-stress environments due to its rapid response and flexibility. Capsule-based self-healing concrete provides a highly customizable solution that can be adapted to meet the specific needs of various construction projects, offering versatile and multi-tiered protection against structural damage.

By understanding the different types of self-healing concrete and their specific mechanisms, engineers and architects can make informed decisions about which type to use in their projects, ensuring enhanced durability, reduced maintenance costs, and improved safety over the lifespan of their structures.

How Does Self-Healing Concrete Work?

The concept of self-healing concrete is based on a straightforward yet ingenious principle: incorporate healing agents directly into the concrete mix that can autonomously activate in response to crack formation. This innovation is designed to extend the lifespan of concrete structures by minimizing the need for manual repairs and reducing maintenance costs. Each type of self-healing concrete employs a unique mechanism to achieve this, but the ultimate goal remains consistent — to automatically repair cracks and restore the structural integrity of the concrete.

Steps in the Self-Healing Process:

- Crack Detection: The process begins with the detection of cracks within the concrete. These cracks may result from thermal expansion, contraction, load-induced stresses, or environmental factors such as freeze-thaw cycles. As cracks develop, they expose the embedded healing agents to environmental factors like air and moisture. The size and frequency of cracks can vary, but the self-healing mechanism is designed to respond promptly, regardless of these variables.

- Activation of Healing Agents: Upon exposure to air and moisture, the healing agents embedded within the concrete become activated. The type of healing agent determines the specific activation process. For instance:

- In bacterial concrete, water and oxygen penetrate the cracks and activate dormant bacteria, which start to metabolize embedded nutrients.

- In polymer-based systems, the rupture of microcapsules releases liquid healing agents into the crack.

- In capsule-based systems, a similar release mechanism is triggered, but with a broader range of potential healing agents, including mineral-based compounds.

- Crack Sealing: After activation, the healing agents work to fill and seal the cracks. The sealing process differs depending on the type of self-healing concrete:

- Bacterial concrete: Bacteria produce calcium carbonate (limestone) as a metabolic byproduct, which precipitates and fills the crack.

- Polymer or capsule-based systems: The released adhesive or chemical compound flows into the crack and hardens, forming a durable seal. The polymerization process involves a chemical reaction that transforms the liquid agent into a solid, impermeable material, effectively blocking further ingress of water and air.

- Restoration of Structural Integrity: The primary objective of the self-healing process is to restore the concrete’s integrity. By filling the cracks, the healing agents prevent further damage and maintain the structure’s durability. This restoration is critical in preventing the propagation of cracks, which could otherwise lead to structural failure. Moreover, self-healing concrete can maintain its load-bearing capacity and resist further environmental degradation.

Repeated Self-Healing Cycles:

One of the remarkable features of self-healing concrete is its ability to undergo multiple self-healing cycles over its lifespan. The effectiveness of these cycles depends on the type and quantity of healing agents embedded in the concrete. Some self-healing concretes are designed to heal minor cracks repeatedly, ensuring long-term durability, while others are formulated to activate once for larger, more significant cracks. For instance, bacterial concrete can potentially heal cracks multiple times as long as sufficient nutrients and dormant bacteria remain. In contrast, capsule-based systems may be limited to a single activation unless multiple generations of capsules are embedded.

Basilisk Self-Healing Concrete: A Game Changer?

Basilisk self-healing concrete represents a significant advancement in the field of self-healing materials. Developed by the Dutch company Basilisk, this innovative concrete incorporates a specific strain of bacteria capable of surviving within the concrete matrix for up to 200 years. This remarkable longevity ensures that the bacteria remain available to heal cracks throughout the concrete’s service life.

Key Features of Basilisk Self-Healing Concrete:

- Efficiency and Longevity: The bacteria used in Basilisk self-healing concrete can repair cracks up to 0.8 mm wide. This capability makes it highly effective for a wide range of structural applications, including those that experience frequent or significant stress. The efficiency of the bacteria in sealing cracks means that structures built with Basilisk concrete require less frequent maintenance, significantly reducing life-cycle costs.

- Mechanism of Action: When cracks form, the dormant bacteria are exposed to water and oxygen, triggering their activation. These bacteria consume calcium lactate (included in the concrete mix) and produce calcium carbonate (limestone) as a byproduct. The limestone precipitates in the cracks, sealing them from the inside out and restoring the concrete’s structural integrity. This process effectively prevents the ingress of harmful substances like water and chlorides, which could otherwise lead to steel reinforcement corrosion.

- Environmental and Economic Benefits: Basilisk self-healing concrete offers substantial environmental benefits by reducing the need for frequent repairs and replacements, thereby minimizing the carbon footprint associated with concrete production and repair. The ability of the bacteria to remain dormant and functional for up to 200 years also means that structures built with this concrete can potentially have extended service lives, further contributing to sustainability.

- Growing Adoption in Europe: Basilisk self-healing concrete is gaining traction in Europe, particularly in countries like the Netherlands, where sustainable construction practices are highly valued. Several projects have successfully incorporated this technology, including bridges, tunnels, parking structures, and water management facilities. The growing use of Basilisk concrete is a testament to its reliability, cost-effectiveness, and sustainability.

Real-World Applications and Benefits

Is self-healing concrete being used in real-world applications? Absolutely. The adoption of self-healing concrete is expanding across various sectors, particularly in infrastructure and civil engineering projects. The technology’s ability to autonomously repair cracks and extend the lifespan of concrete structures has made it an attractive option for many applications.

Key Benefits of Self-Healing Concrete:

- Reduced Maintenance Costs: One of the most significant benefits of self-healing concrete is its potential to drastically reduce maintenance costs. By autonomously repairing cracks as they form, self-healing concrete minimizes the need for costly and labor-intensive repairs. This is especially valuable for infrastructure projects, such as bridges and highways, where maintenance work can cause significant disruptions and additional expenses.

- Extended Structural Lifespan: Self-healing concrete enhances the durability and longevity of structures by preventing cracks from propagating and reducing the risk of structural failure. The autonomous repair of cracks ensures that the concrete maintains its load-bearing capacity and resistance to environmental degradation, thereby extending the lifespan of the structure.

- Improved Safety: Cracks and deteriorating concrete can pose serious safety hazards, particularly in high-traffic areas or critical infrastructure such as bridges, tunnels, and airports. Self-healing concrete helps mitigate these risks by maintaining structural integrity and preventing cracks from widening or leading to catastrophic failures.

- Environmental Sustainability: Self-healing concrete contributes to environmental sustainability by reducing the need for repairs and replacements. This, in turn, lowers the carbon footprint associated with concrete production and repair activities. Moreover, the reduced demand for raw materials and energy consumption aligns with global efforts to promote sustainable construction practices.

Notable Examples of Self-Healing Concrete in Use:

- Infrastructure Projects: In the Netherlands and the UK, self-healing concrete has been successfully implemented in several infrastructure projects, including bridges and highways. These projects aim to reduce long-term maintenance costs and improve the durability and resilience of critical transportation networks.

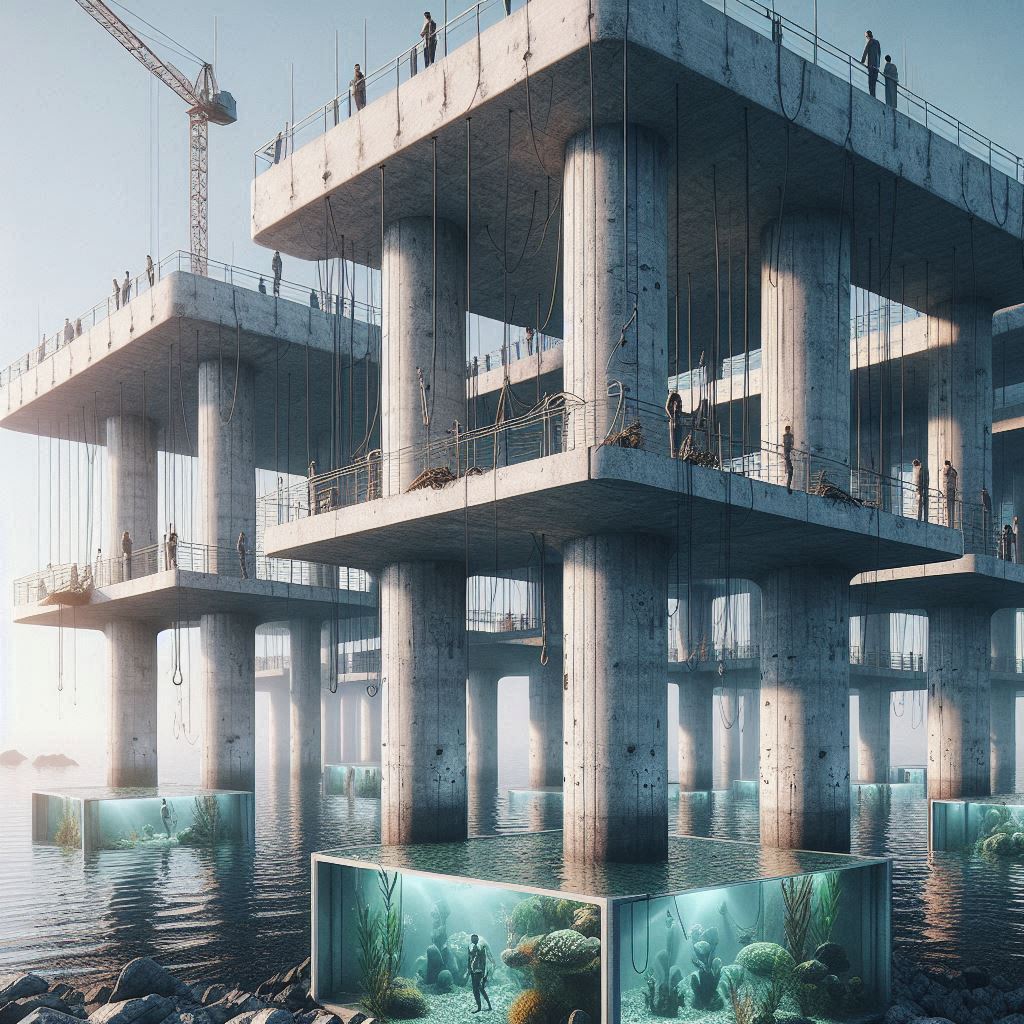

- Marine Structures: Marine environments pose significant challenges for traditional concrete due to constant exposure to saltwater, which can lead to rapid degradation. Self-healing concrete is being used in ports, sea walls, and other coastal defenses to combat these harsh conditions and extend the lifespan of marine structures.

- Buildings: Innovative architectural projects are increasingly adopting self-healing concrete to enhance the longevity and sustainability of both commercial and residential buildings. These projects benefit from reduced maintenance requirements and improved safety, particularly in regions prone to seismic activity or extreme weather conditions.

Sources-

- Self Healing concrete in the Netherlands by the water world

- Self-healing concrete for Marine structure

Future Potential and Innovations in Self-Healing Concrete

The future of self-healing concrete looks incredibly promising, with ongoing research focused on improving the efficiency, cost-effectiveness, and capabilities of these materials. Several exciting developments are on the horizon, which could further revolutionize the construction industry.

Emerging Innovations:

- Regenerative Concrete: Researchers are developing new forms of regenerative concrete that can continuously self-heal over long periods. These materials are designed to maintain a constant state of readiness to repair minor damages as they occur, without exhausting their healing capacity. The use of advanced healing agents that can regenerate themselves or sustain multiple cycles of activation is a key area of focus.

- Advanced Materials Integration: The integration of advanced materials, such as graphene and carbon nanotubes, into self-healing concrete is being explored to enhance its mechanical properties and self-healing capabilities. These materials can provide additional strength, flexibility, and conductivity, which could lead to improved self-healing responses and extended durability.

- Novel Healing Agents: Beyond traditional healing agents, new materials such as shape-memory alloys, smart hydrogels, and biomimetic compounds are being tested to provide more responsive and reliable self-healing capabilities. These agents are designed to respond to specific triggers, such as temperature changes or mechanical stress, providing tailored healing responses for different environmental conditions and applications.

- Nanotechnology and Smart Sensors: The integration of nanotechnology and smart sensors could revolutionize self-healing concrete by enabling real-time monitoring and repair of structural damage. Nanosensors embedded within the concrete could detect the onset of cracks at a micro-scale, triggering localized self-healing responses before visible cracks develop. This proactive approach could significantly enhance the safety and durability of structures.

The Road Ahead:

As self-healing concrete technology continues to advance, the cost of these innovative materials is expected to decrease, making them more accessible for a broader range of applications. The potential for self-healing concrete to transform the construction industry is immense, offering a sustainable, cost-effective solution to the age-old problem of concrete cracking. The continued evolution of self-healing concrete holds great promise for the future, with the potential to redefine the standards of durability, safety, and sustainability in construction.

Conclusion

Self-healing concrete represents a significant leap forward in the construction industry, offering a sustainable solution to one of the most common problems — cracking. By understanding how self-healing concrete works and the different types available, such as bacterial concrete and Basilisk self-healing concrete, we can better appreciate the benefits and future potential of this innovative material. As research continues and technology evolves, the use of self-healing concrete is set to become a standard practice in sustainable construction, paving the way for safer, more durable, and environmentally friendly structures.

Explore other interesting blogs: