Polyurethane: Biodegradability, Biocompatibility, Toxicity, and Sustainability

Polyurethane (PU) is widely used in various industries, from construction to medical devices. Its versatility, durability, and adaptability make it indispensable in modern manufacturing. However, as environmental concerns rise and the demand for sustainable and safe materials increases, questions regarding the recyclability, toxicity, and biodegradability of polyurethane have gained significant attention.

In this blog post, we’ll delve into polyurethane biocompatibility, and the questions like Is polyurethane toxic? is polyurethane toxic when dry? ? is polyurethane biodegradable? for a sustainable future.

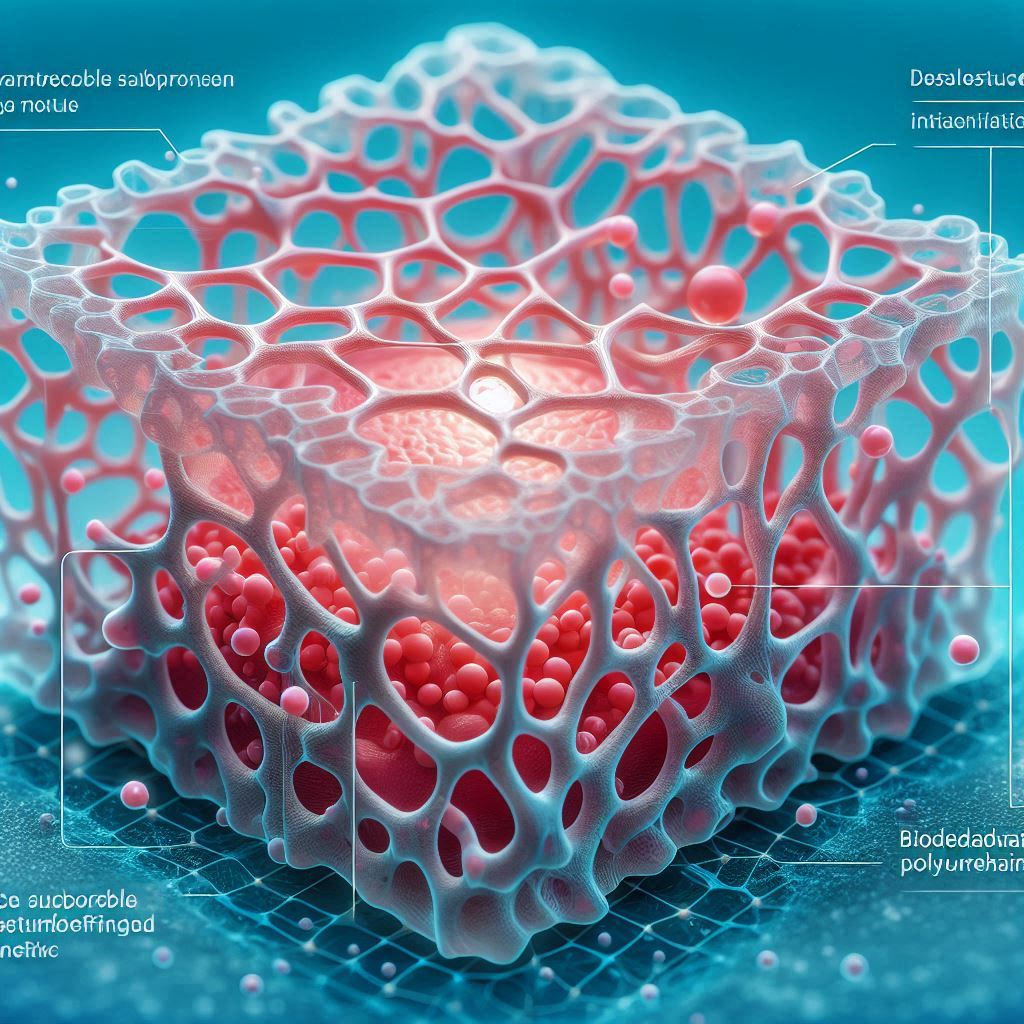

Polyurethane Biodegradables: A Breakthrough in Tissue Engineering

As advancements in materials science continue to shape the future of medicine, polyurethanes biodegradable (PUs) have emerged as a revolutionary solution in tissue engineering. With their unique combination of mechanical properties and biocompatibility, biodegradable PUs are now playing a critical role in developing scaffolds that promote tissue regeneration while naturally degrading in the body.

In this blog, we’ll explore not only how biodegradable polyurethanes are transforming tissue engineering but also dive into the chemistry, sustainability, and wider applications of this remarkable material.

What is Polyurethane?

Polyurethane is a highly versatile and durable polymer that has become integral to various industries, including construction, automotive, textiles, and consumer goods. This adaptability stems from its chemical structure and the ability to modify its properties to suit a wide range of applications. Polyurethane can exist as a rigid foam, flexible elastomer, or a durable coating, making it invaluable for everything from insulation panels to car seats and waterproof fabrics.

Historical Development and Evolution

Polyurethane was first developed in the late 1930s by Dr. Otto Bayer, who discovered the potential of polyaddition polymerization to create a novel class of materials. Since its inception, polyurethane has undergone significant advancements. Initially used primarily in coatings and adhesives, its applications rapidly expanded during World War II due to its resilience and versatility. The post-war era saw the rise of polyurethane foams, which revolutionized industries such as furniture and construction due to their lightweight and insulating properties.

In recent decades, the focus has shifted towards sustainability, leading to the development of bio-based polyurethane biodegradables. These newer forms are derived from renewable resources like soybean oil, castor oil, and even recycled materials. Bio-based polyurethanes are increasingly used in medical devices, packaging, and automotive parts, contributing to a more sustainable and circular economy.

Read More- Biography of Otto Bayer

Applications Across Industries

Polyurethane’s adaptability has led to its widespread use across numerous sectors:

- Construction: In construction, polyurethane is utilized in insulation panels, sealants, and adhesives, helping to improve energy efficiency and reduce noise.

- Automotive: The automotive industry benefits from polyurethane’s lightweight and durable nature, which is used in car seats, dashboards, and even exterior panels.

- Textiles: Polyurethane coatings are applied to fabrics to make them water-resistant and durable, used in items ranging from rainwear to upholstery.

- Consumer Products: From mattresses to footwear, polyurethane’s flexibility and cushioning properties make it a common choice for comfort and durability.

Environmental Considerations and Future Trends

As the global focus on sustainability intensifies, the environmental impact of polyurethane production and disposal has come under scrutiny. Traditional polyurethane, being petroleum-based, poses challenges in terms of recyclability and biodegradability. However, advances in bio-based polyurethanes offer a promising alternative. Researchers are exploring ways to enhance the biodegradability of polyurethanes without compromising their performance, making them suitable for applications like medical implants that degrade naturally within the body.

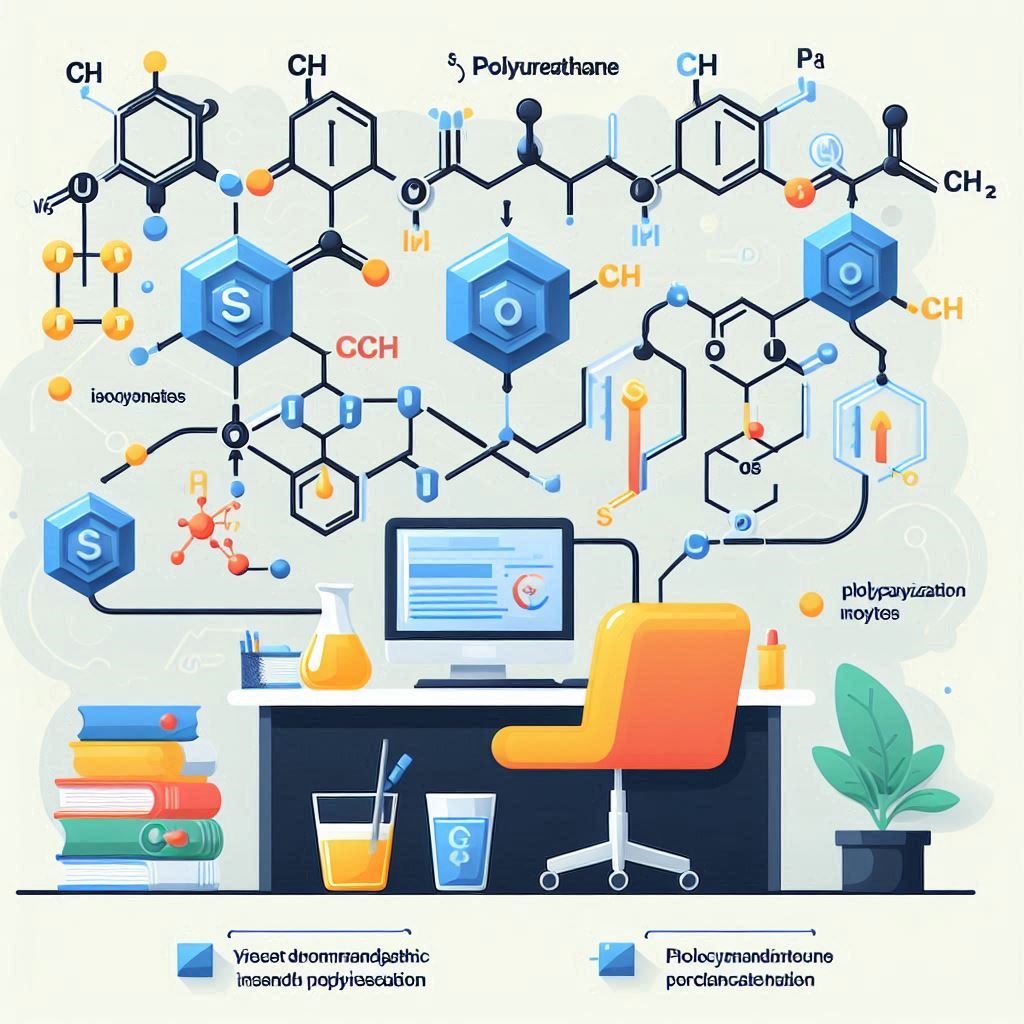

How is Polyurethane Made?

Polyurethane production involves the polymerization of isocyanates with polyols, a process that allows for the creation of materials with a wide spectrum of physical properties. This chemical reaction is highly versatile, enabling the production of anything from soft foams to hard, structural components.

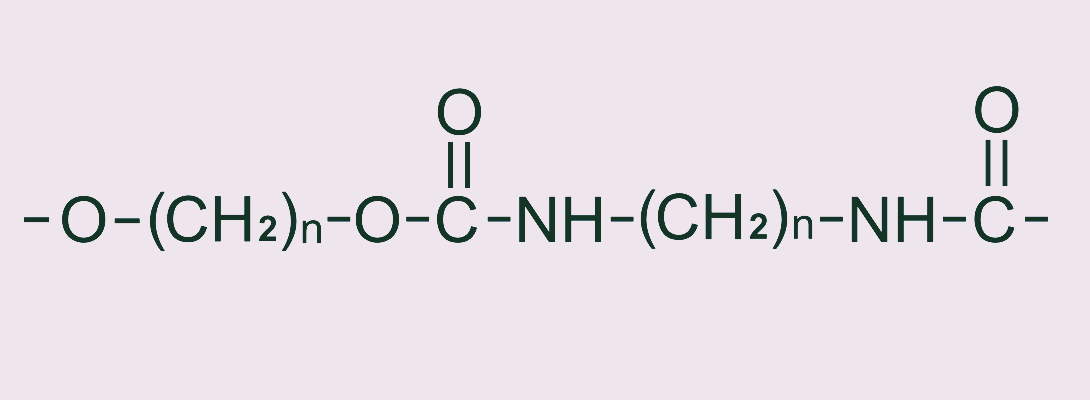

The Polymerization Process

The basic chemical reaction to form polyurethane involves the combination of a diisocyanate and a polyol. Diisocyanates are highly reactive chemicals that, when mixed with polyols, initiate the polymerization process, resulting in the formation of polyurethane. By adjusting the types and ratios of diisocyanates and polyols, manufacturers can control the final product’s properties, such as its hardness, flexibility, and resistance to chemicals.

- Rigid Polyurethane Foams: Used primarily for insulation, these foams are created by introducing blowing agents into the polymerization process, causing the mixture to expand into a rigid, lightweight material.

- Flexible Polyurethane Foams: Commonly found in mattresses and cushions, these foams are designed for comfort and flexibility, with a cell structure that allows for easy compression and recovery.

- Coatings and Elastomers: By altering the chemical composition, polyurethanes can be made into durable coatings that protect surfaces or elastomers that are both flexible and tough.

Bio-Based Polyurethanes and Green Chemistry

The rise of bio-based polyurethanes is one of the most significant developments in the industry. Traditional polyurethanes are derived from petrochemicals, raising concerns about their environmental impact. In contrast, bio-based polyurethanes use polyols derived from renewable resources like vegetable oils, corn, and even waste materials. This shift not only reduces reliance on fossil fuels but also opens up new possibilities for creating biodegradable or recyclable polyurethane products.

Biodegradability and Sustainability

One of the most exciting aspects of biodegradable polyurethanes is their ability to break down naturally in the body or environment. Traditional polyurethanes, while useful, contribute to plastic pollution due to their resistance to degradation. In contrast, biodegradable polyurethanes are engineered to degrade over time into non-toxic byproducts, typically through hydrolysis or enzymatic reactions.

This property is crucial for their use in tissue engineering, where materials need to provide temporary support before being safely absorbed or excreted by the body. Additionally, their sustainability profile makes them an attractive option for reducing the environmental impact of medical waste.

Applications of Biodegradable Polyurethane in Tissue Engineering

Tissue Scaffolds

Biodegradable polyurethanes are widely used to create scaffolds that serve as temporary structures for growing new tissue. These scaffolds provide the necessary support for cells to grow, proliferate, and eventually form functional tissues. As the tissue regenerates, the polyurethane scaffold gradually degrades, leaving behind natural tissue.

Drug Delivery Systems

Another promising application is in the development of controlled drug delivery systems. By incorporating therapeutic agents into biodegradable polyurethane matrices, scientists can create systems that release drugs over time, improving the effectiveness of treatments and reducing the need for multiple doses.

Wound Healing and Regenerative Medicine

Biodegradable polyurethanes are also being explored for use in skin grafts, wound dressings, vascular grafts, and nerve regeneration. Their ability to support cellular growth while gradually degrading makes them ideal for a variety of regenerative medical applications.

Challenges and Future Directions

While biodegradable polyurethanes offer significant benefits, there are still challenges to overcome. One of the main obstacles is balancing biodegradability with mechanical strength. In tissue engineering, materials must be strong enough to support tissue growth yet flexible enough to degrade safely. Finding the right combination of durability and degradation rate remains an area of active research.

Looking ahead, innovations in biodegradable polyurethane technology are focusing on enhancing bioactivity, improving manufacturing processes, and expanding applications beyond the medical field. Researchers are also working to further reduce costs and improve scalability, making these materials accessible for widespread use.

Other Potential Applications of Biodegradable Polyurethane

Sustainable Packaging

Beyond the biomedical field, biodegradable polyurethanes are finding use in environmentally friendly packaging solutions. These materials offer the strength and durability needed for packaging while breaking down into harmless substances over time, addressing the growing issue of plastic waste.

Agriculture

In agriculture, biodegradable polyurethanes are being used to develop controlled-release fertilizers and biodegradable films for crop protection. These films help reduce the environmental impact of traditional plastic films, which often accumulate as waste in the ecosystem.

Is Polyurethane Biodegradable?

Polyurethane, in its traditional form, is not biodegradable, primarily due to the strong chemical bonds in its structure that prevent microorganisms from breaking it down easily. This presents a significant environmental challenge, especially as PU waste accumulates in landfills. However, recent developments in biodegradable polyurethanes (BD-PUs) are offering hope for a more eco-friendly alternative.

Recent Developments:

- Enzyme-Catalyzed Degradation: Researchers are developing polyurethanes that degrade more easily in natural environments through enzyme-catalyzed reactions. This technology is crucial in biomedical applications where biodegradable materials are necessary for tissue scaffolds and implants.

- Bio-based Polyurethanes: New formulations of polyurethanes made from plant-based resources such as soy or castor oil are emerging, significantly reducing their carbon footprint. These bio-based polyurethanes are also more likely to degrade over time.

According to a recent study from The University of Manchester, biodegradable polyurethanes can be engineered to break down in biologically active environments, which can pave the way for more sustainable materials used in medical implants and even packaging.

The University of Manchester, biodegradable polyurethanes

Polyurethane Biocompatibility in Medical Applications

Polyurethane’s flexibility and strength make it an ideal candidate for medical applications, such as implants, artificial organs, and tissue scaffolds. However, biocompatibility is a crucial factor, especially when it comes to materials intended to interact with human tissues.

Why Polyurethane is Biocompatible: Polyurethanes, especially those designed for medical use, exhibit excellent biocompatibility due to their ability to be tailored at the molecular level. This allows for the creation of polymers that interact favorably with living tissues, minimizing immune response and promoting healing.

Recent Advancements:

- 3D-Printed Polyurethane Scaffolds: The advent of 3D printing has opened new doors in tissue engineering. Using biocompatible polyurethanes, researchers are now able to create custom tissue scaffolds that promote cell growth and regeneration.

- Anti-Bacterial Polyurethane Coatings: Researchers at Northwestern University recently developed a polyurethane coating that not only promotes biocompatibility but also has anti-bacterial properties. This innovation is expected to reduce infection rates in medical implants.

Is Polyurethane Recyclable?

Recycling polyurethane has historically been a challenge due to its complex polymer structure. Most of the polyurethane ends up in landfills, but advances in chemical recycling methods are now making it possible to break down and reuse this material.

Recent Developments:

- Chemical Recycling: New chemical recycling methods can depolymerize polyurethane back into its monomers. These monomers can then be reused to make fresh polyurethane products. This technique is being explored by companies like Covestro as part of their sustainability drive.

- Polyurethane Foam Recycling: Rigid polyurethane foam, commonly used in insulation, is being recycled more efficiently by breaking it down into smaller particles that can be reintegrated into new foam products. This process not only reduces waste but also decreases the energy footprint associated with creating new foam from raw materials.

Comparison Chart of Traditional vs. Bio-Based Polyurethane:

| Criteria | Traditional Polyurethane | Bio-Based Polyurethane |

|---|---|---|

| Raw Material Source | Petrochemical-based (fossil fuels) | Renewable resources (e.g., soybean oil, castor oil, algae) |

| Environmental Impact | Higher carbon footprint, non-renewable resources | Lower carbon footprint, sustainable and renewable sources |

| Toxicity | Contains harmful chemicals like isocyanates, potential VOC emissions | Generally lower toxicity, some formulations non-toxic |

| Biodegradability | Non-biodegradable, contributes to long-term plastic pollution | Potential for biodegradability, especially in specific formulations |

| Applications | Widely used in construction, automotive, textiles, and consumer goods | Emerging applications in medical devices, packaging, and sustainable products |

| Recyclability | Limited recyclability, often ends up in landfills | Potential for chemical recycling, contributes to circular economy |

| Cost | Generally lower due to established production processes | Can be higher due to newer technologies and limited production scale |

| Performance Characteristics | Proven performance in durability and strength across various industries | Comparable performance with added environmental benefits |

| Allergies and Sensitivities | Can trigger allergies and respiratory issues | Potentially lower risk of allergies and sensitivities |

| Regulatory Compliance | Subject to regulations on chemical use and disposal | Aligns with sustainability and green initiatives, potential regulatory benefits |

Is Polyurethane Toxic?

Traditional polyurethane, particularly in its liquid form, contains toxic chemicals such as diisocyanates, which can cause respiratory issues and skin irritation. However, once polyurethane cures, it becomes inert, significantly reducing its toxicity. Still, concerns remain about its long-term impact on human health and the environment.

Is Polyurethane Toxic When Dry? While most polyurethane becomes non-toxic once fully cured, there can be concerns about volatile organic compounds (VOCs) that may be released over time. VOCs can cause indoor air quality issues and affect human health if present in large amounts. Choosing low-VOC or zero-VOC polyurethane products is essential for minimizing these risks.

Recent Innovations:

- Non-Toxic Polyurethanes: Researchers are working on creating non-toxic polyurethanes that do not contain harmful isocyanates. This is done by using alternative chemicals that are safer for both workers handling the material and end-users .

- Green Polyurethane: Developed by Hybrid Coating Technologies, this innovative non-toxic polyurethane eliminates the use of hazardous isocyanates, making it one of the safest forms of polyurethane on the market today.

Moving Towards Sustainability: The Future of Polyurethane

The environmental impact of polyurethane has driven researchers and industries to focus on developing more sustainable versions. Here are a few ways that sustainability is being enhanced in the world of polyurethane:

- Bio-Based Polyurethane: One of the most significant advancements is the development of bio-based polyurethanes derived from renewable resources like vegetable oils and algae. These polyurethanes are not only less toxic but also exhibit potential biodegradability.

- Circular Economy for Polyurethanes: Companies like BASF are working on establishing a circular economy for polyurethane materials, where waste polyurethane is recycled and reintroduced into the manufacturing process. This reduces both waste and the need for virgin raw materials.

Conclusion

Polyurethane remains a versatile material that plays an essential role in our everyday lives. As industries and researchers strive for sustainability and safety, advancements in biodegradable, biocompatible, and recyclable polyurethanes are paving the way for a greener and safer future. From innovative recycling techniques to biocompatible medical devices, the future of polyurethane looks promising, ensuring that it continues to serve our needs without compromising the health of our planet.

If you’re looking to minimize your environmental impact, consider using eco-friendly, low-toxicity, or recyclable polyurethane products. The advancements discussed here are just the beginning, as more industries adopt these sustainable technologies.

Explore more such topics-