Revolutionizing Construction with Recycled Concrete

The construction industry is at a crossroads. As global urbanization accelerates, the demand for construction materials, especially concrete, is skyrocketing. However, this comes at a significant environmental cost. The cement industry, a critical component of concrete production, is responsible for a substantial portion of global carbon dioxide (CO2) emissions. But what if we could create a new type of concrete that not only reduces these emissions but also recycles waste materials and captures CO2 from the atmosphere? This is the promise of calcium carbonate concrete, a groundbreaking material developed by researchers at the University of Tokyo. Discover how recycled concrete and low-carbon solutions reduce CO2 and promote sustainable building practices.

The Environmental Cost of Conventional Concrete

Concrete is the most widely used man-made material on Earth, essential for constructing buildings, bridges, roads, and other infrastructure. However, the environmental impact of concrete production is profound. The cement industry alone is responsible for approximately 7% of global CO2 emissions, a significant contributor to climate change. This high level of emissions is primarily due to the production process, which involves heating limestone (calcium carbonate) to high temperatures to produce calcium oxide, a key ingredient in cement.

The process of manufacturing cement releases CO2 in two ways: first, through the combustion of fossil fuels to generate the necessary heat, and second, from the chemical reaction that occurs when limestone is heated. The latter, known as calcination, is responsible for about 60% of the emissions from cement production. Given the scale of global cement production, the environmental impact is staggering.

Furthermore, the demand for concrete is only expected to grow as the global population increases and urbanization continues. This makes it imperative to find alternative methods and materials that can reduce the carbon footprint of the construction industry.

A Novel Solution: Calcium Carbonate Concrete

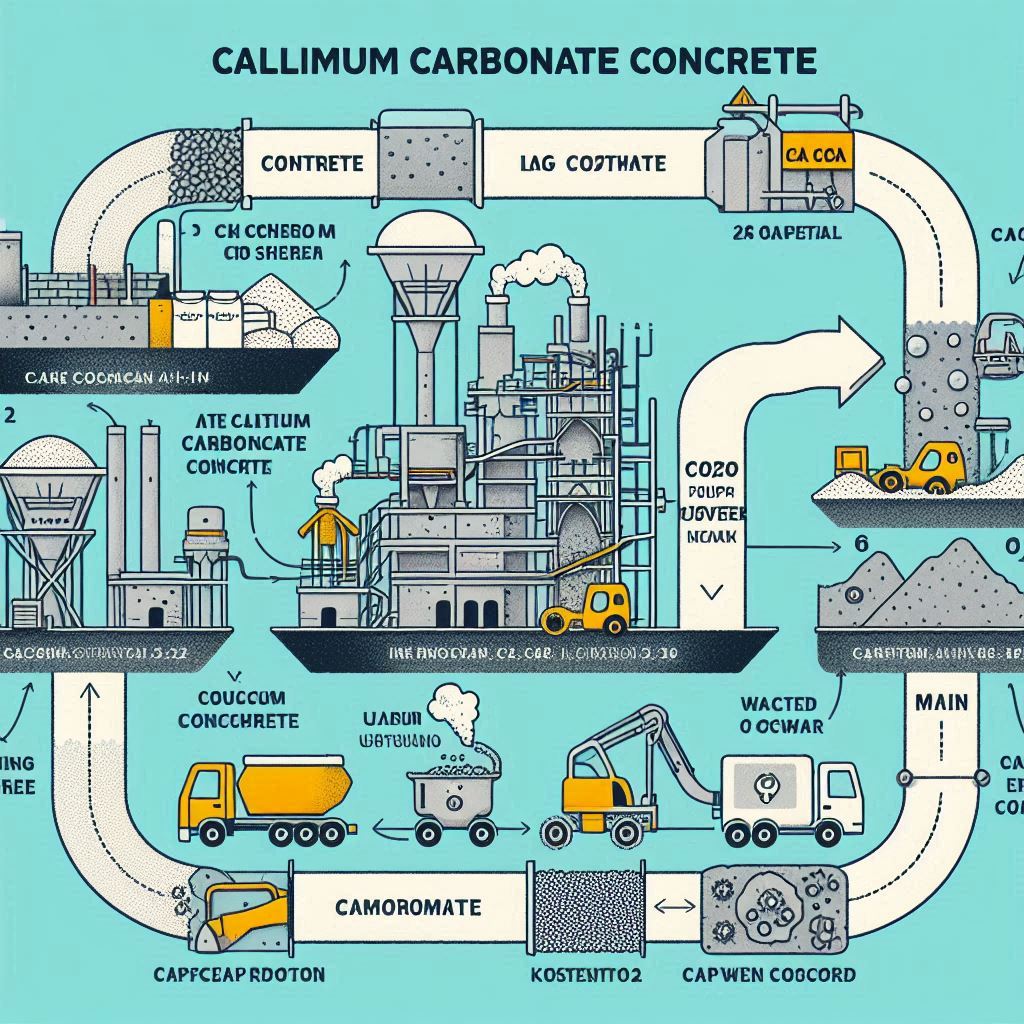

In response to the urgent need for more sustainable construction materials, Professor Ippei Maruyama and Professor Takafumi Noguchi from the Department of Architecture at the University of Tokyo have developed a new type of concrete known as calcium carbonate concrete. This innovative material is made by combining waste concrete with CO2 captured from the air or industrial exhaust gases, effectively turning two waste products into a valuable construction material.

The inspiration for calcium carbonate concrete comes from nature. Professor Maruyama was inspired by the way certain aquatic organisms, such as coral and shellfish, use calcium carbonate to build their shells and skeletons. Over time, these organisms fossilize, forming hard calcium carbonate deposits. Maruyama wondered if a similar process could be applied to concrete, using calcium extracted from waste concrete and CO2 to form a stable, durable material.

This process offers several significant environmental benefits. First, it recycles waste concrete, reducing the need for new raw materials and minimizing the environmental impact of construction waste disposal. Second, it captures CO2, a major greenhouse gas, from the atmosphere or industrial processes, effectively turning a pollutant into a useful resource.

How Calcium Carbonate Concrete is Made

The process of creating calcium carbonate concrete begins with the collection of waste concrete. This material, which would otherwise be discarded, is then crushed to extract calcium. In conventional concrete production, calcium is typically obtained by heating limestone to high temperatures, a process that releases large amounts of CO2. In contrast, the method developed by Professors Maruyama and Noguchi involves extracting calcium from waste concrete at much lower temperatures, significantly reducing the energy required and the associated CO2 emissions.

Once the calcium is extracted, it is combined with CO2 to form calcium carbonate. This reaction mimics the natural process of mineralization that occurs in the shells and skeletons of marine organisms. The resulting calcium carbonate is then used to create a new type of concrete.

One of the challenges with this process is ensuring that the calcium carbonate concrete has the necessary strength and durability for construction purposes. Traditional concrete is valued for its strength, which allows it to support heavy loads and withstand harsh environmental conditions. Calcium carbonate concrete, while promising, is currently not as strong as conventional concrete. However, it is suitable for certain applications, such as the construction of small buildings or structures in areas where natural resources are scarce.

Potential Applications and Benefits

The development of calcium carbonate concrete opens up new possibilities for the construction industry, particularly in regions where traditional building materials are in short supply. In areas where natural limestone deposits are limited, the ability to create concrete from waste materials and atmospheric CO2 could be a game-changer. This could be particularly beneficial in developing countries, where access to raw materials and the infrastructure to process them may be limited.

In addition to its potential to reduce CO2 emissions, calcium carbonate concrete offers other environmental benefits. For example, by recycling waste concrete, the material helps to reduce the amount of construction debris that ends up in landfills. This is particularly important given the scale of global construction activity, which generates millions of tons of waste each year.

Furthermore, the ability to capture CO2 from the air or industrial processes and incorporate it into a building material could play a role in efforts to combat climate change. While the amount of CO2 that can be captured through this process is relatively small compared to global emissions, it represents a step in the right direction. In combination with other carbon capture and utilization technologies, calcium carbonate concrete could contribute to a broader strategy for reducing greenhouse gas emissions.

Real-World Applications: Recycled Concrete in Action

Highway 427, Toronto, Canada: A Pioneering Project

In a bid to reduce its environmental footprint, the Ontario Ministry of Transportation embarked on a groundbreaking project to incorporate recycled concrete aggregate (RCA) into the construction of Highway 427 in Toronto, Canada. Completed in 2021, this massive infrastructure project marked a significant step towards sustainable road construction.

The project involved recycling concrete from demolished structures and crushing it into smaller aggregates to be used as a base material for the highway’s pavement. This innovative approach not only diverted a substantial amount of concrete waste from landfills but also contributed to the project’s overall sustainability.

While challenges such as ensuring the quality and consistency of the recycled aggregate were encountered, the project successfully demonstrated the feasibility of using recycled concrete in large-scale infrastructure projects.

Veera Horsakulthai Housing Complex, Bangkok, Thailand: A Sustainable Living Model

Veera Horsakulthai, a renowned Thai architect and urban planner, showcased the potential of recycled concrete in the realm of sustainable housing with her eponymous housing complex in Bangkok, Thailand. Completed in 2020, the project aimed to create a community that minimized its environmental impact while providing high-quality living spaces.

The complex incorporated recycled concrete into its foundation, walls, and flooring, demonstrating the material’s versatility in residential construction. By utilizing recycled concrete, the project reduced the demand for virgin materials, lowered carbon emissions, and contributed to a circular economy.

The Veera Horsakulthai housing complex serves as a testament to the fact that sustainable construction and aesthetic appeal can coexist, inspiring other developers to adopt similar practices.

Expanding Horizons: Recycled Concrete in Diverse Applications

Beyond highways and housing, recycled concrete has found applications in a wide range of construction projects, showcasing its versatility and environmental benefits:

- Bridges and Culverts: In regions prone to natural disasters, recycled concrete has been used to construct bridges and culverts that are both durable and sustainable. For example, Researchers at EPFL in Switzerland have developed a prototype footbridge constructed from reinforced concrete blocks repurposed from the obsolete walls of a building undergoing renovation.

- Commercial Buildings: To achieve LEED certification and meet sustainability goals, many commercial buildings are incorporating recycled concrete into their construction. For instance,“Kunsthaus Zurich” by David Chipperfield – Zurich, Switzerland- Recycled Concrete

Chipperfield’s project exemplifies a dual approach to material reuse: not only is 95% of the concrete used in the building recycled, but the project itself involves the expansion and restoration of the Zurich Art Museum. This demonstrates how restoration can be an effective way to recycle and repurpose existing structures. - Concrete Products: The production of concrete blocks, pavers, and other precast elements using recycled concrete has gained traction in recent years. These products offer a sustainable alternative to traditional concrete while maintaining desired performance characteristics.

Sources-

Challenges and Future Directions

While the development of calcium carbonate concrete is an exciting advancement, there are still several challenges that need to be addressed before it can be widely adopted. One of the main challenges is increasing the strength and durability of the material. Current prototypes of calcium carbonate concrete are not as strong as traditional concrete, limiting their use to smaller-scale projects. Researchers are working on ways to enhance the material’s properties, potentially by refining the production process or by adding other materials to the mix.

Another challenge is scaling up the production of calcium carbonate concrete. The current process is still in the experimental stage, and producing the material on a large scale will require further research and development. This includes finding ways to make the process more energy-efficient and cost-effective, as well as ensuring that the material can be produced consistently at a high quality.

There is also the question of how calcium carbonate concrete will perform over time. Traditional concrete has been used for centuries, and its long-term durability is well understood. Calcium carbonate concrete, on the other hand, is a new material, and its performance over decades or even centuries is not yet known. Long-term studies will be necessary to evaluate how the material holds up under different environmental conditions and loads.

Despite these challenges, the potential of calcium carbonate concrete is undeniable. As research continues, it is likely that the material will become stronger, more durable, and more versatile, making it a viable alternative to traditional concrete in a wider range of applications.

The Broader Implications for Sustainable Construction

The development of calcium carbonate concrete is part of a broader movement towards more sustainable construction practices. The construction industry has long been recognized as a major contributor to environmental degradation, from deforestation and habitat destruction to the emission of greenhouse gases. As the world grapples with the challenges of climate change and resource depletion, there is an urgent need to rethink how we build our cities and infrastructure.

One of the key principles of sustainable construction is the idea of a circular economy, where materials are reused and recycled rather than being discarded after a single use. Calcium carbonate concrete aligns with this principle by turning waste materials into a valuable resource. This not only reduces the environmental impact of construction but also helps to conserve natural resources, which are becoming increasingly scarce in many parts of the world.

In addition to developing new materials like calcium carbonate concrete, the construction industry is also exploring other strategies for reducing its environmental footprint. These include the use of renewable energy sources in construction processes, the design of energy-efficient buildings, and the adoption of green building certifications and standards. Together, these efforts represent a comprehensive approach to making the built environment more sustainable.

Conclusion: A Vision for the Future of Construction

The invention of calcium carbonate concrete is a promising step forward in the quest for more sustainable building materials. By recycling waste concrete and capturing CO2 from the air, this innovative material has the potential to reduce the environmental impact of the construction industry significantly. While there are still challenges to overcome, the research being conducted at the University of Tokyo and elsewhere is paving the way for a future where concrete is not only strong and durable but also environmentally friendly.

As we look to the future, the development of new materials like calcium carbonate concrete will be essential for building a more sustainable world. The construction industry, which has historically been a major source of environmental harm, now has the opportunity to lead the way in creating a more sustainable built environment. With continued research and innovation, materials like calcium carbonate concrete could become the standard for construction, helping to reduce emissions, conserve resources, and protect our planet for future generations.

In this vision of the future, buildings will not only serve as shelters and workplaces but also as part of a larger ecosystem that supports the health and well-being of the planet. From the materials we use to the way we design and construct our buildings, the choices we make today will shape the world of tomorrow. Calcium carbonate concrete is just one example of how innovation can drive positive change, offering a glimpse of a future where construction is both sustainable and resilient.

If you found this article on the innovative use of recycled concrete intriguing, be sure to check out my other blog posts.