Introduction

The electric vehicle (EV) revolution is accelerating, and with it comes an increasing demand for advanced EV battery technology. Companies like Octillion Power Systems and Tata Battery are at the forefront of this transformation, driving innovations in lithium-ion battery technology to enhance efficiency, sustainability, and cost-effectiveness.

As governments worldwide push for stricter emissions regulations and automakers invest heavily in EV development, the need for high-performance, reliable, and long-lasting EV batteries has never been greater. Octillion Power Systems and Tata Battery are playing crucial roles in shaping the future of EV batteries, focusing on improved energy density, faster charging capabilities, and longer lifespans.

In this blog, we will explore how Octillion Power Systems is revolutionizing the EV industry with cutting-edge lithium-ion battery solutions and its significant impact on the global EV market. Additionally, we will delve into Tata Battery’s contributions, highlighting how its advancements align with the growing demand for sustainable and efficient EV power storage solutions.

What is Octillion Power Systems?

Company Overview

Octillion Power Systems is a global leader in lithium-ion battery pack manufacturing, specializing in advanced energy storage solutions for electric vehicles (EVs), commercial fleets, and other industrial applications. The company has a strong presence in North America, India, and China, with a total annual production capacity of 25GWh across multiple manufacturing facilities.

Founded with a mission to accelerate the adoption of EV technology through high-performance and cost-effective battery solutions, Octillion focuses on innovation, mass-volume production, and rapid customization for diverse mobility and energy storage needs.

Key Contributions to the EV Battery Industry

Octillion has supplied over 1.5 million battery systems, contributing significantly to the growth of the global EV market. It is known for its:

- High-voltage lithium-ion battery packs for passenger cars, commercial fleets, and electric buses.

- Custom-built battery solutions tailored to specific vehicle architectures, allowing manufacturers greater flexibility.

- Strategic expansion in North America, China, and India, enabling large-scale production and reducing reliance on foreign imports.

Recent Innovations & Global Impact

- In 2025, Octillion inaugurated a state-of-the-art battery factory in Reno, Nevada, known as “Nevada One,” which will enhance domestic EV battery production with a 1GWh annual capacity. This facility integrates advanced automation, robotics, and human labor to ensure high-quality manufacturing.

- The company continues to expand its footprint in Europe and India, focusing on sustainable and high-energy-density battery solutions for diverse automotive and industrial applications.

Partnerships & Collaborations

Octillion collaborates with leading automakers and fleet operators to deliver high-performance, cost-effective battery solutions. Its global manufacturing network supports Tier-1 original equipment manufacturers (OEMs), ensuring rapid scale-up and deployment of cutting-edge battery technology

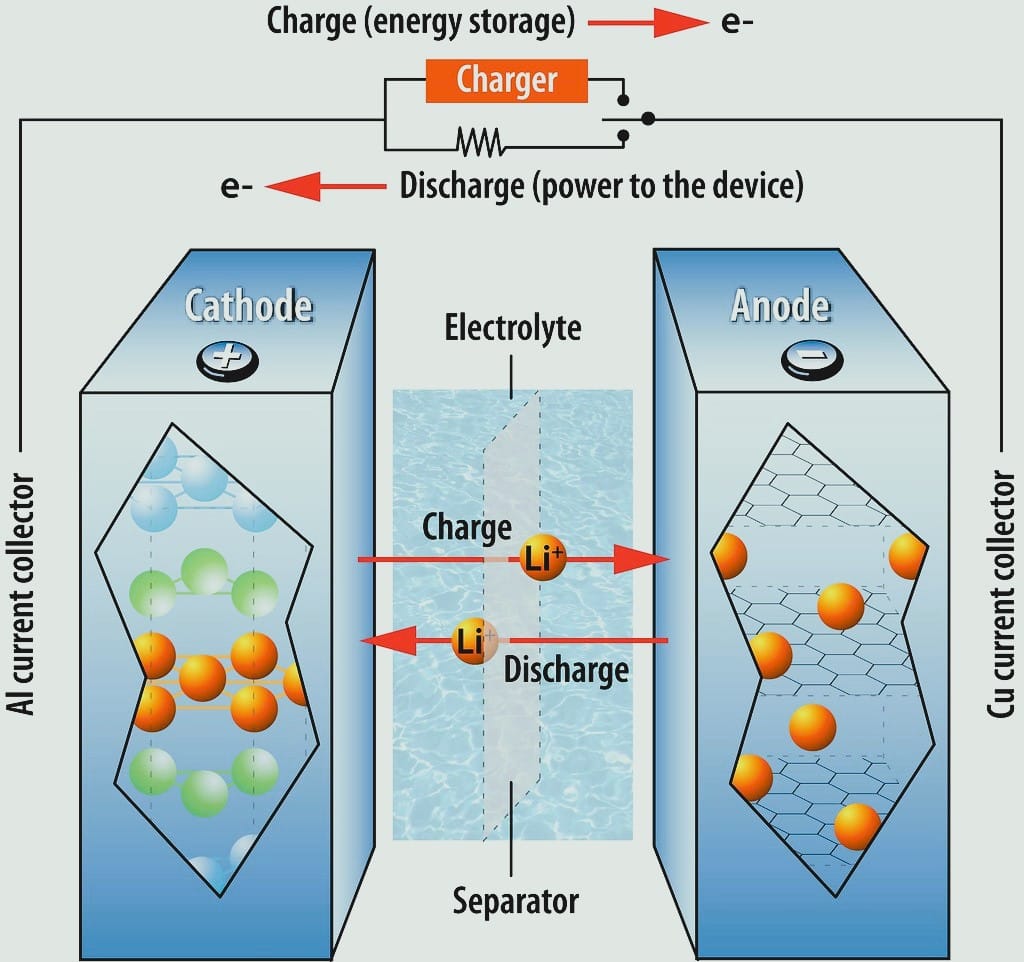

Octillion Battery Technology: How It Works

Battery Chemistry and Structure

Octillion Power Systems specializes in high-density lithium-ion battery packs for various electric vehicles, including passenger cars, trucks, buses, and off-road vehicles. These batteries leverage advanced lithium-ion chemistry, ensuring optimal energy storage and longevity. The company’s proprietary Battery Management System (BMS) is designed in California and helps regulate temperature, voltage, and charge cycles to enhance battery efficiency and lifespan.

Energy Density and Efficiency

Octillion’s battery packs stand out due to their high energy density and efficiency, making them competitive in the EV market. The company produces 1,500 battery packs per day and has supplied over 300,000 EV batteries globally, with vehicles powered by Octillion batteries covering more than 4.5 billion kilometers. Their custom-built battery solutions cater to different EV applications, allowing manufacturers to optimize their powertrain performance.

Safety Features and Longevity Improvements

Octillion integrates advanced thermal management and safety mechanisms in its battery packs. Their systems undergo extensive thermal modeling to prevent overheating and ensure durability. Additionally, their BMS offers real-time monitoring and control, reducing risks such as overcharging and short circuits.

Tata Battery: India’s Role in the EV Revolution

Tata’s Involvement in Battery Production

Tata Group is actively contributing to India’s EV revolution through Tata Chemicals and Tata Power, focusing on lithium-ion battery manufacturing and EV infrastructure. Tata Auto Comp, in collaboration with Tata Motors, develops battery packs for Tata’s EV models like the Nexon EV, Tigor EV, and upcoming Tiago EV. Their commitment aligns with India’s push toward clean energy and sustainable mobility.

Key Projects and Battery Models for EVs

- Tata Motors’ Nexon EV and Tigor EV are among India’s best-selling electric cars, powered by Tata lithium-ion battery packs.

- Tata Power’s EV charging network is expanding nationwide, enhancing infrastructure for electric mobility.

- Gigafactory plans: Tata Group is investing in a 20 GWh battery cell production facility in India to strengthen domestic manufacturing and reduce reliance on imports.

Comparison with Octillion’s Solutions

While Octillion focuses on global mass production and high-density lithium-ion packs, Tata Batteries are primarily designed for the Indian market, aligning with Make in India initiatives. Octillion supplies batteries for various global OEMs, whereas Tata Motors’ batteries are integrated within their own EV ecosystem. Octillion’s expertise in high-voltage battery packs for electric buses and heavy-duty vehicles also gives them a competitive edge in fleet electrification

Octillion vs. Tata Battery: A Comparative Analysis

Performance Comparison – Energy Output, Efficiency, and Durability

Octillion Power Systems and Tata Battery both contribute significantly to the EV battery market, but they differ in performance and target applications. Octillion specializes in high-density lithium-ion batteries designed for passenger cars, trucks, and buses, with a strong emphasis on advanced battery management systems and high energy output. The company has delivered over 300,000 EV batteries globally, powering vehicles such as the Wuling Hongguang Mini EV and electric buses in India.

Tata Batteries, on the other hand, cater more specifically to the Indian EV market. With India’s growing EV sector, Tata Motors has positioned itself as a leader by integrating lithium-ion batteries in vehicles like the Tata Nexon EV. The company’s focus is on affordability, energy efficiency, and durability, making its batteries highly suitable for India’s climate and road conditions.

Manufacturing Scale and Global Distribution

Octillion operates battery manufacturing facilities in the U.S., China, and India, allowing it to cater to a diverse global market. The company ships approximately 1,500 battery packs per day, reflecting its strong international presence. Tata Battery, while primarily focused on India, is also expanding its capabilities through domestic manufacturing initiatives supported by government incentives like the Production-Linked Incentive (PLI) scheme.

Sustainability and Eco-Friendliness of Both Brands

Sustainability plays a crucial role in both companies’ strategies. Octillion focuses on reducing CO₂ emissions through energy-efficient battery solutions, claiming that its batteries have already contributed to lowering emissions by over 1.4 million metric tons. Tata, aligned with India’s net-zero commitment by 2070, is working on sustainable battery production by exploring alternative battery chemistries such as lithium iron phosphate (LFP) and nickel manganese cobalt (NMC), which offer higher energy density while being more environmentally friendly.

How Octillion and Tata Are Shaping the Future of EV Batteries

The Shift Towards Solid-State and High-Energy-Density Batteries

Both Octillion and Tata are preparing for the next generation of EV battery technology. While Octillion continues to improve lithium-ion energy density and efficiency, industry trends suggest a shift toward solid-state batteries, which offer higher energy capacity and better safety features. Tata, leveraging India’s evolving EV battery ecosystem, is also exploring high-nickel NMC and LMFP (lithium manganese iron phosphate) technologies to enhance energy storage and reduce costs.

AI and Smart Battery Management Systems

Octillion integrates advanced circuit boards in its battery management systems, designed to optimize battery performance and longevity. This includes features like thermal modeling and energy efficiency optimization. Tata is also investing in AI-driven battery monitoring and predictive maintenance to improve EV performance in Indian road and climate conditions.

Recycling and Sustainability Initiatives in Battery Manufacturing

With the rising demand for EVs, battery recycling and circular economy initiatives are becoming crucial. Octillion’s approach includes localized battery manufacturing to minimize carbon footprints, while Tata is exploring battery recycling partnerships in India to ensure sustainable disposal and reuse of battery materials.

Both companies play a pivotal role in the evolving EV landscape, with Octillion driving global innovation and Tata shaping India’s self-reliant battery ecosystem. Their contributions are essential to the future of sustainable transportation.

Challenges and Opportunities in the EV Battery Market

The EV battery industry is evolving rapidly, but it faces significant challenges, particularly in sourcing raw materials, addressing environmental concerns, and improving recycling processes.

Raw Material Sourcing and Ethical Concerns

One of the biggest hurdles in EV battery production is the procurement of essential raw materials such as lithium, cobalt, and nickel. The global demand for these minerals is expected to outstrip supply in the coming years, leading to price volatility and supply chain disruptions. Countries such as China dominate battery material processing, raising concerns over geopolitical dependencies. Moreover, mining operations often raise ethical issues, such as child labor in cobalt mining in the Democratic Republic of Congo, pushing manufacturers toward more sustainable sourcing strategies. Governments are now emphasizing localized supply chains to mitigate risks, as seen in the U.S. Inflation Reduction Act and the European Union’s Critical Raw Materials Act, which encourage regional processing and battery manufacturing.

Battery Degradation and Recycling Limitations

Lithium-ion batteries have a limited lifespan, and their efficiency degrades over time. As EV adoption increases, the number of decommissioned batteries is also expected to rise. While battery recycling can recover valuable materials, existing processes such as pyrometallurgical and hydrometallurgical recycling are energy-intensive and have limitations in recovering certain elements like lithium and graphite. However, new techniques such as direct recycling, which preserves cathode structures for reuse, are being developed to improve efficiency and reduce waste.

Future Market Trends and Investment Opportunities

Despite these challenges, the EV battery market presents significant investment opportunities. The global push toward net-zero emissions and the rising adoption of EVs are expected to drive the battery industry to $95 billion in annual revenue by 2040. Companies investing in solid-state battery technology, advanced battery chemist working, AI-driven battery management systems are likely to gain a competitive edge. Governments are also offering subsidies and incentives to promote sustainable battery production and recycling.

The Role of Octillion and Tata in India’s EV Ecosystem

India is witnessing a rapid transition toward electric mobility, with companies like Octillion Power Systems and Tata leading the battery manufacturing landscape. With strong government support and increasing consumer demand, the Indian EV battery market is poised for massive growth.

Government Policies and Subsidies for Battery Manufacturing

The Indian government has launched several initiatives to boost domestic EV battery production. The Production Linked Incentive (PLI) Scheme offers financial incentives for setting up advanced battery manufacturing plants. Additionally, the Faster Adoption and Manufacturing of Electric Vehicles (FAME) II scheme provides subsidies for EV purchases, indirectly fueling battery demand. The government is also pushing for indigenous battery cell production to reduce dependency on imports, aligning with its “Atmanirbhar Bharat” (self-reliant India) vision.

Growth of EV Adoption in India

India’s EV market is expected to grow exponentially, with projections estimating that EVs will account for 30% of total vehicle sales by 2030. Tata Motors, with its EV models like the Nexon EV, is leading the charge, while startups and foreign investments are also entering the market. The need for localized battery production is increasing as global supply chain disruptions have highlighted the risks of import reliance.

Strategic Importance of Domestic Battery Production

Octillion Power Systems and Tata are at the forefront of India’s battery manufacturing efforts. Octillion has been investing in advanced battery technologies and supply chain diversification, while Tata Chemicals has established battery cell production facilities to cater to the domestic and international markets. These efforts are crucial for India’s transition to a sustainable EV ecosystem, reducing dependency on imported lithium-ion batteries and fostering technological advancements.

FAQ

What is Octillion Power Systems and what role do they play in EV batteries?

Octillion Power Systems is a global provider of advanced lithium-ion battery packs for electric vehicles (EVs) and energy storage. They specialize in customized battery solutions for passenger cars, buses, trucks, and two-wheelers, focusing on performance, safety, and scalability.

How is Tata involved in the EV battery industry?

Tata Group, through Tata AutoComp and Tata Motors, is investing heavily in battery manufacturing, localization, and EV infrastructure in India. Their collaboration with Octillion highlights Tata’s ambition to reduce import dependency and build a self-reliant EV ecosystem.

Why is the Tata–Octillion partnership important for India’s EV future?

India’s EV adoption depends on affordable, reliable, and locally produced batteries. The partnership combines Tata’s manufacturing and market presence with Octillion’s battery expertise, accelerating India’s transition to clean mobility.

What type of battery technology are they focusing on?

Currently, the focus is on lithium-ion batteries, particularly LFP (Lithium Iron Phosphate) chemistry, known for safety, longer life cycles, and cost-effectiveness—critical for Indian road and climate conditions.

How will this impact the cost of electric vehicles in India?

Localizing battery production reduces reliance on imports, cutting logistics and supply costs. This will likely make EVs more affordable for Indian consumers while ensuring better after-sales service and replacement options.

What does this mean for EV range and performance?

With advanced lithium-ion packs and future innovations like solid-state batteries, EVs will achieve longer driving ranges, faster charging, and improved durability, making them more practical for both urban and long-distance travel.

Are Tata and Octillion working on battery recycling or second-life use?

Yes, both companies are exploring battery recycling and repurposing for energy storage applications. This helps create a circular economy, reducing waste and ensuring that old EV batteries find new life in solar and grid storage systems.

How does this partnership align with India’s EV policy goals?

The collaboration supports India’s FAME II scheme and 2030 EV vision, promoting local manufacturing, lowering carbon emissions, and reducing dependence on fossil fuels. It is a strategic step toward making India a global EV hub.

Conclusion

Octillion Power Systems and Tata are shaping the future of India’s EV battery market through technological innovation and strategic partnerships. As the global demand for EVs grows, efficient and sustainable battery solutions will play a critical role in transforming transportation. Investing in next-generation battery technologies and recycling infrastructure will be essential to overcoming supply chain challenges and ensuring long-term sustainability.

Explore More Insights on the Future of Energy and Technology

If you found this article intriguing, you’ll love these other deep dives into the world of energy innovation and cutting-edge technology:

- Invention of Battery Technology

Uncover the fascinating evolution of battery technology and how it’s shaping the future of energy storage and electric vehicles. - Unveiling Dark Oxygen: Mining Seabed for Battery Materials

Dive into the discovery of dark oxygen, a revolutionary material mined from the seabed, and its potential to transform battery manufacturing. - Hydrogen vs. Electric: The Ultimate Energy Showdown

Compare the strengths and weaknesses of hydrogen fuel cells and electric batteries in the race to power a sustainable future. - Electricity Generating Slime: Nature’s Powerhouse

Explore the surprising world of bioelectricity and how slime molds could become a groundbreaking source of renewable energy. - Advanced Energy Storage: Powering the Future

Learn about the latest breakthroughs in energy storage systems and how they’re enabling the widespread adoption of renewable energy. - Invention of the Electricity: A Journey Through Time

Take a step back in time to explore the invention of electricity and how it revolutionized the modern world.

Why Stop Here?

The future of energy is brimming with innovation, and these articles are your gateway to understanding the technologies that will shape tomorrow. Keep exploring and stay inspired!