Introduction- The Invention of IC Engine:

The invention of the internal combustion engine (IC engine) stands as a pivotal moment in human history, sparking a revolution that transformed transportation, industry, and society as a whole. From the early prototypes powered by gasoline and steam to the sophisticated four-stroke and two-stroke cycles we see today, the IC engine’s journey is a fascinating tale of innovation, ingenuity, and relentless pursuit of efficiency.

This blog delves into the intriguing story behind the IC engine, exploring the pioneering minds like Nicolaus Otto and Rudolf Diesel who laid the groundwork for this groundbreaking technology. We’ll explore the fundamental principles behind the four-stroke and two-stroke cycles, the distinctive features of each, and their lasting impact on various sectors.

What is an Internal Combustion Engine?

The invention of IC engines has been an important breakthrough in shaping modern transportation and industrial sectors. They are a type of heat engine that utilizes chemical energy stored in fuel and converts it into mechanical energy through the process of combustion. It produced power by burning a mixture of air and fuel in a combustion chamber. This exothermic reaction produces high-pressure and high-temperature gases which are utilized to produce mechanical work. Let’s explore the fascinating journey of IC engine discovery, development, and its various facets.

Understanding the working of IC Engines:

IC engines can be mainly categorized into two types: two-stroke and four-stroke engines. The fundamental difference lies in the number of strokes required to complete a full cycle of combustion.

Four-Stroke IC Engines:

How Does an Internal Combustion Engine Work?

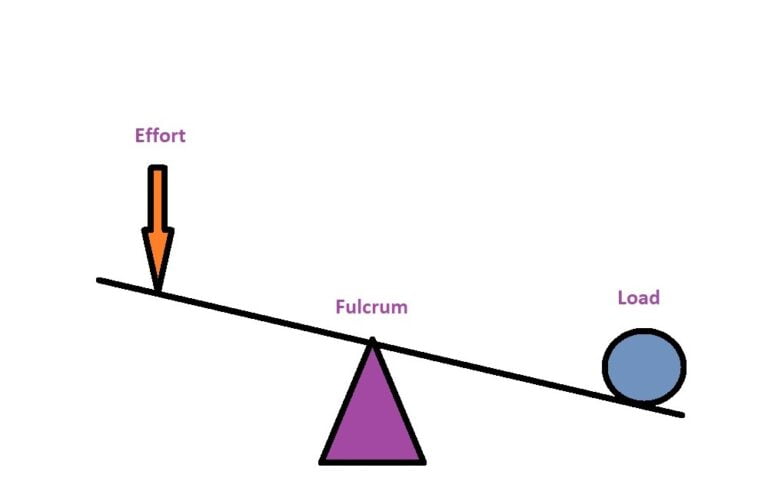

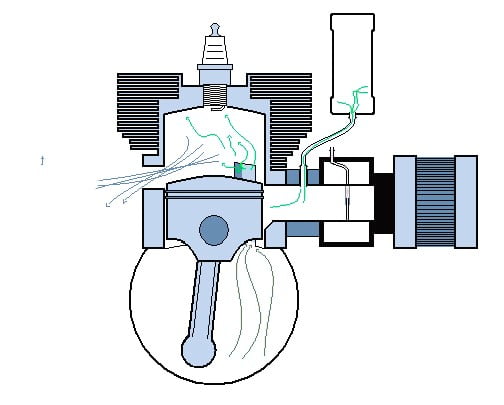

Simply put, an internal combustion engine works & produces mechanical energy by burning fuel inside a confined space (Cylinder). Here’s a simplified breakdown of its operation:

Intake: During the intake stroke, the intake valve opens & it draws in a mixture of air and fuel (gasoline or diesel) into the combustion chamber.

Compression:

At this stage, both inlet and outlet valves are closed and the cam and follower mechanism controls this. The piston starts moving upward, compressing the air-fuel mixture. Due to compression, pressure and temperature in the combustion chamber start increasing.

Ignition: When the piston reaches the top of the cylinder, a spark plug ignites this high temperature & pressurized, highly compressed mixture in the petrol engine. As the spark triggers a controlled explosion, there is a rapid expansion of gases which pushes the piston downward. In the case of diesel engines, ignition happens due to the high temperature achieved by compression itself. To achieve this diesel engines have high compression ratios, where the temperature reaches to the self-ignition temperature of diesel.

Power: The force generated due to rapid expansion of gases due to the combustion of fuel, it drives the piston downward. As the piston moves, it rotates the crankshaft, converting linear motion into rotational motion.

Exhaust: At the end of the power stroke, the piston reaches the bottom limit of the cylinder & and starts moving upward. The exhaust valve opens and the exhaust gases are expelled from the cylinder, making way for a fresh intake of air and fuel to repeat the cycle.

Two-Stroke IC Engines:

In the case of the two-stroke engine, it is a type of internal combustion engine that completes its power cycle in just two strokes of the piston. Two-stroke engines are simpler in design compared to four-stroke engines. But are less fuel-efficient and more polluting due to incomplete combustion of fuel than a four-stroke engine. It is often used in applications where simplicity, high power-to-weight ratios are important, like small motorcycles, chainsaws, and some outboard marine engines. Let’s delve into the workings of a two-stroke engine:

Intake and Compression Stroke:

Intake: The intake begins with the downward movement of the piston creating a partial vacuum in the cylinder. This vacuum draws a mixture of air and fuel into the crankcase from the carburetor through an intake port.

Compression: During compression piston moves back up, and it compresses the air-fuel mixture in the crankcase. This compression forces the intake port to close, sealing off the crankcase from the combustion chamber

Combustion and Exhaust Stroke:

Combustion and Power: When the piston reaches the top of the compression stroke, a spark plug ignites the compressed air-fuel mixture. The combustion of the air-fuel mixture rapidly expands, creating a high-pressure gas that pushes the piston down. This is the power stroke, where the engine generates power in the form of mechanical energy that can be utilized for various applications.

Exhaust: After the power stroke, the piston reaches the bottom of the cylinder, which uncovers the exhaust port and allows the burnt gases to escape from the combustion chamber. At the same time, the upward movement of the piston starts compressing the fresh charge in the crankcase.

Scavenging Process: The scavenging process is one of the important functions of a two-stroke engine, which uses the incoming air-fuel mixture movement to clear out the remaining exhaust gases from the combustion chamber. This is achieved through the design of ports and the geometry of the cylinder.

Differentiating IC Engines from EC Engines:

Internal combustion (IC) engines and External Combustion (EC) engines may sound similar, but they operate differently. In an IC engine, the combustion process happens within the engine itself, but in an EC engine (like a steam engine), combustion happens outside the engine like boilers, producing high-pressure steam that is supplied to power the engine.

Internal Combustion Engines (IC engines) have a rich history of development, and many pioneering scientists and engineers have contributed to their discovery and advancement. Let us delve into the remarkable journey of IC engine discovery, highlighting key milestones and the individuals who shaped this transformative technology.

Timeline of IC Engine Development and Scientists:

Early Concepts and Experiments:

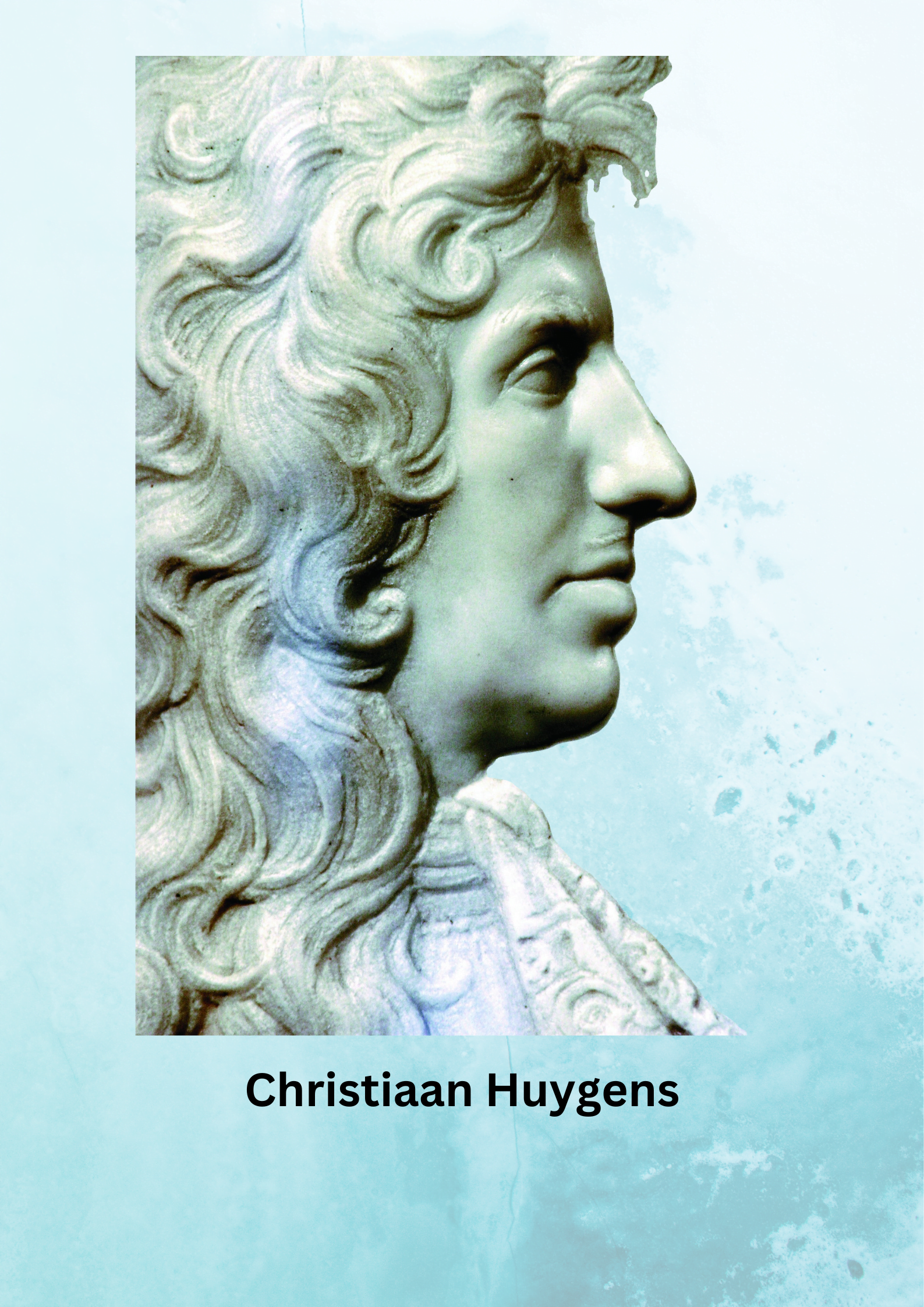

1673-Christiaan Huygens patents the first internal combustion engine design:

This Dutch physicist and mathematician is credited with conceptualizing the first internal combustion engine, using gunpowder as fuel. However, his design, which relied on a piston and cylinder arrangement, faced significant technical limitations. The explosive nature of gunpowder made it impractical for controlled combustion within the engine, and the technology of the time lacked the materials and engineering necessary to withstand the immense pressures generated. Despite these challenges, Huygens’s work laid the groundwork for future advancements in engine development.

Cover Story of Christiaan Huygens:

Huygens was a prolific inventor and scientist who made significant contributions to various fields, including astronomy, optics, and mathematics. His invention of the pendulum clock in 1656 revolutionized timekeeping accuracy, and his discovery of the rings of Saturn in 1655 expanded our understanding of the solar system. Huygens’s patent for the internal combustion engine, though never built, demonstrates his forward-thinking approach and his attempt to harness the power of combustion for practical applications.

Unknown Facts about Huygens:

- Huygens was a skilled musician and composer. He even designed a new type of keyboard instrument called the “celestarium.”

- He was a close friend and collaborator of Gottfried Wilhelm Leibniz, another prominent mathematician and philosopher of the time.

- Huygens’s work on probability theory laid the foundation for modern statistical methods.

Historical References:

The concept of using gunpowder for propulsion existed before Huygens’s engine design. In the 13th century, Chinese inventors developed gunpowder rockets, which were primarily used for military purposes. However, Huygens’s work is significant because it represents one of the earliest attempts to harness the power of combustion for a controlled and practical application, paving the way for future advancements in engine technology.

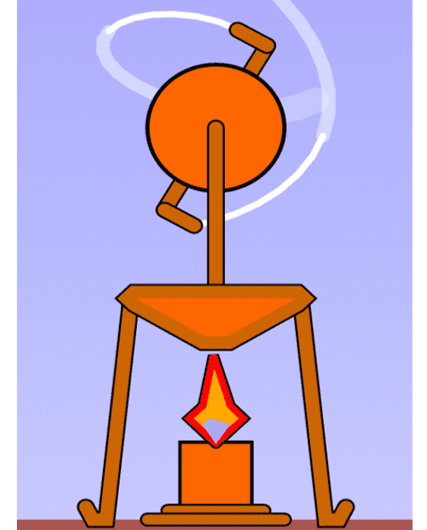

1679-Denis Papin invents the steam digester:

This French physicist and inventor is known for his contributions to the development of the steam engine. His invention, the steam digester, is considered a precursor to the internal combustion engine due to its use of a piston and cylinder and the concept of harnessing power pressure. Papin’s digester used steam pressure to cook food quickly and efficiently, but it also demonstrated the potential of using steam to generate mechanical work.

Cover Story of Denis Papin:

Papin was a brilliant inventor with a keen interest in harnessing the power of steam. He collaborated with Robert Boyle on early experiments with the vacuum pump and later developed the steam digester, which laid the foundation for his work on steam engines. Papin’s innovative spirit and contributions to steam technology paved the way for future advancements that would revolutionize transportation and industry.

Unknown Facts about Papin:

- Papin faced several challenges and setbacks throughout his career, including financial difficulties and lack of recognition for his inventions.

- He is credited with coining the term “atmospheric pressure” and made significant contributions to the understanding of thermodynamics.

- Papin’s work on steam engines influenced the development of the Newcomen engine, which was one of the first commercially successful steam engines.

Historical References:

Papin’s invention of the steam digester came amidst a growing interest in harnessing the power of steam during the Scientific Revolution. Earlier advancements, such as the steam turbine development by Hero of Alexandria in ancient Greece, laid the groundwork for Papin’s work. His steam digester, though not directly related to internal combustion engines, served as a stepping stone in understanding the principles of using pressure and pistons to generate mechanical power, which would later be applied in the development of the internal combustion engine.

Key Players and Breakthroughs:

1794: Robert Street and the Dawn of Liquid Fuel Engines:

Invention:

British inventor Robert Street patents the first internal combustion engine fueled by liquid hydrocarbon, likely derived from petroleum. This engine utilized a piston and cylinder design, similar to the steam engines of the time, but with a crucial difference: combustion occurred within the cylinder rather than in a separate boiler. Street’s engine used an external flame to ignite the air-fuel mixture, marking a significant step toward the self-contained internal combustion engines of the future.

Journey of the Inventor:

Unfortunately, detailed information about Robert Street’s life and career is scarce. However, his patent for the liquid-fueled engine demonstrates his innovative spirit and understanding of internal combustion’s potential for practical applications.

Historical References:

1807: The Pyréolophore and the Power of Dust Explosions:

Invention:

French engineers Nicéphore Niépce and Claude Niépce, better known for their pioneering work in photography, develop the Pyréolophore. This prototype engine, named after the Greek words for “fire” and “thief,” operated on a unique principle: controlled dust explosions. The engine used a mixture of coal dust and air, which was ignited by a spark to create a rapid pressure increase that drove the piston. The Pyréolophore successfully powered a boat on the Saône River, demonstrating the feasibility of using combustion for propulsion.

Journey of the Inventors:

The Niépce brothers were multifaceted individuals with a keen interest in science and technology. Their work on the Pyréolophore, though not commercially successful, showcased their ingenuity and willingness to explore unconventional approaches to harnessing power.

- Historical References:

1860: Étienne Lenoir and the Birth of the Commercial Engine:

Invention:

Étienne Lenoir, a French engineer, builds the first commercially successful internal combustion engine. This single-cylinder engine, fueled by a mixture of air and coal gas, operated on the atmospheric principle. Unlike earlier engines that relied on external flames for ignition, Lenoir’s engine used a spark plug to ignite the fuel mixture within the cylinder, marking a crucial advancement towards modern internal combustion engines. Lenoir’s engine, though not highly efficient, found applications in various industries, including workshops and printing presses, paving the way for further development and widespread adoption of internal combustion technology.

Journey of the Inventor:

Lenoir was a prolific inventor with a diverse range of interests, including electroplating and electric motors. His success with the internal combustion engine established him as a pioneer in the field and laid the foundation for future engine designs that would revolutionize transportation and industry.

Historical References:

1862: Jean Joseph Etienne Lenoir Refines the Design:

Invention:

Building upon the success of his earlier engine, Jean Joseph Etienne Lenoir, likely a relative of Étienne Lenoir, patents an improved gas engine design. This new engine featured better efficiency and control compared to its predecessor. The improvements included a more efficient valve system and a double-acting piston, allowing for power generation on both upward and downward strokes. These advancements further solidified the potential of internal combustion engines for practical applications.

Journey of the Inventor:

While information about Jean Joseph Etienne Lenoir is limited, his contribution to engine development demonstrates the ongoing refinement and innovation that characterized the early years of internal combustion technology.

Historical References:

- “Étienne Lenoir and the Lenoir Gas Engine“

- “History of the Internal Combustion Engine“

- “Lenoir engine” by Britannica website

Additional Information:

- While limited information exists about Jean Joseph Etienne Lenoir specifically, his patent for the improved gas engine serves as a valuable historical record of his contribution to engine development.

- Further research into patent records and contemporary publications from the 1860s might reveal additional details about his life and work.

- Exploring the evolution of engine design from Étienne Lenoir’s earlier engine to Jean Joseph Etienne Lenoir’s improved version provides insights into the gradual advancements that led to more efficient and practical internal combustion engines.

1864: Nicolaus Otto and the Dawn of the Four-Stroke Cycle:

Invention:

German engineer Nicolaus Otto, in collaboration with Eugen Langen and Franz Rings, patents the first commercially successful gas engine based on the four-stroke cycle. This revolutionary design, known as the Otto cycle, involved four distinct strokes: intake, compression, combustion, and exhaust. Unlike previous engines that relied on atmospheric pressure for operation, the Otto cycle engine utilized in-cylinder compression, significantly improving efficiency and power output compared to earlier designs like Lenoir’s engine.

Journey of the Inventor:

Nicolaus Otto, driven by a desire to create a more efficient and practical engine, dedicated himself to overcoming the limitations of existing designs. His relentless pursuit of innovation led to the development of the four-stroke cycle, which remains the cornerstone of most internal combustion engines today.

Historical References:

-

- “Nikolaus Otto and the Four-Stroke Cycle Engine” by ThoughtCo website

- “The Internal Combustion Engine: How Nikolaus Otto Changed the World” by Smithsonian Magazine website

- “The Early Development of the Internal Combustion Engine” by SAE International website

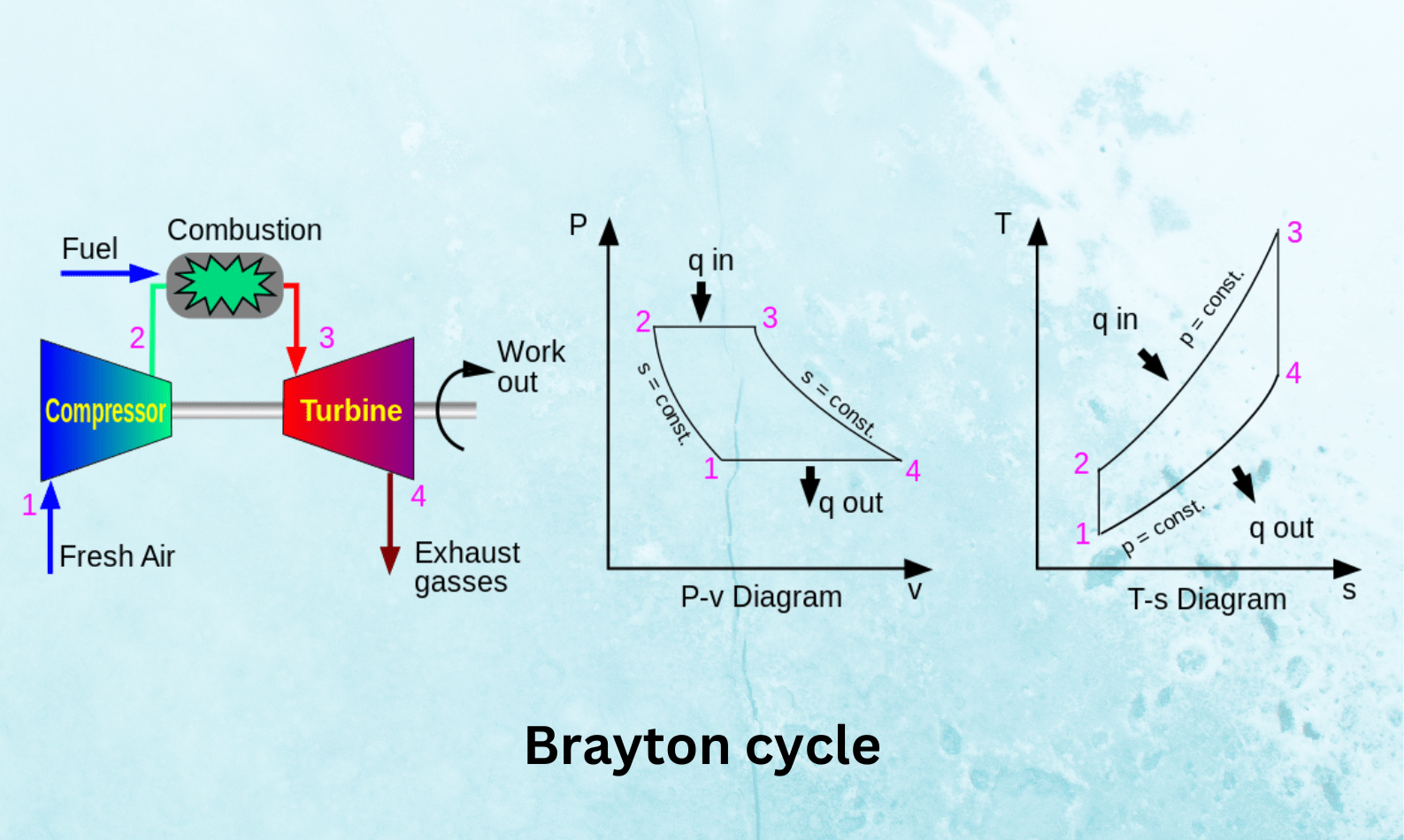

1872: George Brayton and the Rise of Liquid Fuels:

Invention:

American engineer George Brayton patents the first commercially successful liquid-fueled internal combustion engine. This engine, unlike previous designs that primarily relied on gaseous fuels like coal gas, operated on the Brayton cycle and used a mixture of air and kerosene. Brayton’s invention demonstrated the feasibility of using liquid fuels in internal combustion engines, paving the way for future advancements in fuel options.

Journey of the Inventor:

George Brayton was a prolific inventor with a diverse range of interests, including metallurgy and refrigeration. His work on the liquid-fueled engine showcased his innovative spirit and his understanding of the potential for alternative fuel sources in powering internal combustion engines.

Historical References:

-

-

- “George Brayton and the Brayton Cycle Engine” by Internal Combustion Engine History website

- “The Brayton Cycle: A Stepping Stone to Modern Engines” by Science Direct website

-

1876: Nicolaus Otto and the Birth of the Modern Engine:

Invention:

Building upon his earlier success with the four-stroke cycle, Nicolaus Otto, alongside Gottlieb Daimler and Wilhelm Maybach, patents the compressed charge, four-stroke cycle engine. This refined design, often referred to as the Otto engine, incorporated in-cylinder compression of the air-fuel mixture before ignition, leading to a significant increase in efficiency and power output compared to previous iterations. The Otto engine laid the foundation for most modern gasoline engines, revolutionizing transportation and various industrial applications.

Journey of the Inventors:

This pivotal invention involved the combined efforts of three individuals:

Nicolaus Otto: As mentioned earlier, Otto’s relentless pursuit of innovation played a crucial role in developing the four-stroke cycle.

Gottlieb Daimler: A talented engineer and entrepreneur, Daimler recognized the potential of internal combustion engines for transportation and collaborated with Otto and Maybach to develop practical engine designs.

Wilhelm Maybach: An exceptional engineer and designer, Maybach contributed significantly to refining the engine’s mechanical components and ensuring its efficient operation.

Historical References:

-

-

- “The History of the Internal Combustion Engine” by American Society of Mechanical Engineers

- “The Legacy of the Otto Engine: How a 19th-Century Invention Shaped the Modern World” by Science Direct website

-

1879: Karl Benz and the Birth of the Automobile :

:

Invention:

Karl Benz, a German engineer, patents a reliable two-stroke gasoline engine and installs it in a three-wheeled motor vehicle known as the Patent-Motorwagen. This invention is widely considered the first commercially produced automobile. Benz’s engine featured several innovations, including a crankcase to enclose the moving parts, a carburetor to mix air and fuel, and a spark plug ignition system.

Journey of the Inventor:

Driven by a vision for self-propelled transportation, Benz dedicated himself to developing practical and efficient internal combustion engines. His relentless efforts culminated in the Patent-Motorwagen, which laid the foundation for the global automotive industry.

Historical References:

-

-

- “Karl Benz and the Patent-Motorwagen: The Birth of the Automobile” by Britannica website

-

1882: Daimler and Maybach Push the Boundaries of Speed:

Invention:

German engineers Gottlieb Daimler and Wilhelm Maybach developed the first high-speed gasoline engine. This engine, significantly lighter and faster than previous designs, was installed in a motorbike known as the Reitwagen. This marked a crucial step towards high-performance internal combustion engines and paved the way for future advancements in transportation, particularly motorcycles and automobiles.

Journey of the Inventors:

Daimler and Maybach formed a successful partnership, sharing a passion for innovation and engine development. Their collaboration resulted in groundbreaking advancements in engine design, including lightweight materials and improved efficiency, ultimately contributing to the evolution of various transportation modes.

Historical References:

-

- “The First Automobile: How Daimler and Maybach Changed Transportation” by Mercedes Benz website

1892: Rudolf Diesel and the Age of Efficiency:

Invention:

German engineer Rudolf Diesel invents the first successful compression-ignition internal combustion engine, now known as the diesel engine. This engine operated on the principle of compressing air to high temperatures, igniting fuel without the need for a spark plug. Diesel engines offered greater efficiency compared to gasoline engines and could run on heavier fuels like diesel oil, making it ideal for applications requiring durability and power, such as industrial machinery and later, large vehicles like trucks and ships.

|

| Rudolf Diesel |

Journey of the Inventor:

Diesel dedicated his career to improving engine efficiency and exploring alternative fuels. His invention of the diesel engine revolutionized various industries, impacting transportation, power generation, and agriculture.

Historical References:

-

- “Rudolf Diesel and the Diesel Engine” by Britannica website

1903: The Wright Brothers Take Flight with Internal Combustion Power:

Invention:

The Wright Brothers, Wilbur and Orville, successfully achieve sustained flight with their Flyer aircraft powered by a modified gasoline engine. This marked the beginning of the aviation era. The Wright Brothers significantly modified a commercially available engine, reducing weight and improving efficiency to meet the specific demands of flight.

Journey of the Inventors:

The Wright Brothers were fascinated by the potential of flight and conducted extensive research and experimentation. Their innovative modifications to the internal combustion engine played a pivotal role in their historic achievement, paving the way for the development of airplanes and the aviation industry.

Historical References:

-

- “The Wright Brothers and the Invention of the Airplane” by NASA website

- “How the Wright Brothers Changed the World” by Smithsonian Magazine website

20th Century:

The 20th century witnessed the exponential growth and widespread adoption of internal combustion (IC) engines, transforming various sectors and shaping the modern world. This period was characterized by continuous advancements in engine technology, leading to:

- Increased Efficiency: Engineers focused on optimizing engine design and combustion processes to extract more power from each unit of fuel, resulting in significant improvements in fuel economy.

- Enhanced Power Output: Engine designs evolved to generate greater power, enabling the development of more powerful vehicles, machinery, and power plants.

- Diverse Applications: IC engines found applications in various sectors beyond transportation, including industry, agriculture, construction, and power generation, driving economic growth and development.

Key Inventions and Milestones:

- Development of the Carburetor: The carburetor, invented in the late 19th century, played a crucial role in regulating the air-fuel mixture, enabling smoother engine operation and improved efficiency.

- Electric Ignition Systems: Replacing spark plugs with electric ignition systems provided more reliable and precise control over combustion, leading to better engine performance and fuel economy.

- Superchargers and Turbochargers: These technologies force more air into the engine, increasing power output for applications requiring high performance.

- Fuel Injection: Replacing carburetors with fuel injection systems offered greater control over fuel delivery and combustion, leading to further efficiency gains and reduced emissions.

- Catalytic Converters: Introduced in the latter half of the century, catalytic converters significantly reduced harmful emissions from exhaust gases, addressing environmental concerns.

Impact and Perspectives:

The widespread adoption of IC engines in the 20th century had a profound impact on various aspects of society:

- Transportation: The invention of the automobile revolutionized personal mobility, facilitating the development of suburbs, tourism, and global trade.

- Industrialization: IC engines powered machinery in factories and workshops, enabling mass production and economic growth.

- Agriculture: Mechanized farming equipment powered by IC engines significantly increased agricultural productivity.

- Environmental Concerns: The increasing reliance on IC engines also raised concerns about air pollution and climate change, prompting research into cleaner technologies and alternative fuels.

Historical References:

- “A Brief History of the Internal Combustion Engine” by TUV Nord website

- “The History of the Automobile” by The History Channel website

The 21st century

The 21st century presents a complex landscape for internal combustion (IC) engines. While they remain a dominant force in various sectors, sustainability concerns necessitate a multifaceted approach that balances technological advancements with environmental responsibility. Ongoing research and development efforts focus on several key areas:

Pushing the Efficiency Frontier:

- Advanced Combustion Strategies: Researchers are exploring innovative combustion techniques like homogeneous charge compression ignition (HCCI) and low-temperature combustion (LTC) to improve fuel efficiency and reduce emissions.

- Friction Reduction: Advancements in materials, coatings, and lubrication aim to minimize friction losses within the engine, leading to improved fuel economy.

- Engine Downsizing and Turbocharging: Combining smaller, lighter engines with efficient turbochargers can deliver comparable power output while consuming less fuel.

Mitigating Environmental Impact:

- Advanced Emission Control Systems: Continuously evolving catalytic converters, particulate filters, and exhaust gas recirculation systems are crucial for capturing and reducing harmful pollutants from engine exhaust.

- Alternative Fuels: Research into biofuels, hydrogen, and synthetic fuels seeks to lessen reliance on traditional fossil fuels and their associated environmental impact.

- Electrification Integration: Hybrid and plug-in hybrid electric vehicles (HEVs and PHEVs) combine IC engines with electric motors, offering reduced emissions and improved fuel efficiency, particularly in urban driving conditions.

Embracing a Multifaceted Approach:

- Policy and Regulations: Stringent emission regulations and incentives for cleaner technologies play a crucial role in driving innovation and accelerating the adoption of sustainable solutions.

- Infrastructure Development: Building a robust infrastructure for alternative fuels, such as hydrogen refueling stations and charging networks for electric vehicles, is essential for supporting the transition towards a sustainable transportation ecosystem.

- Consumer Awareness and Education: Educating consumers about the environmental impact of different transportation options and promoting responsible driving habits can contribute to a more sustainable future.

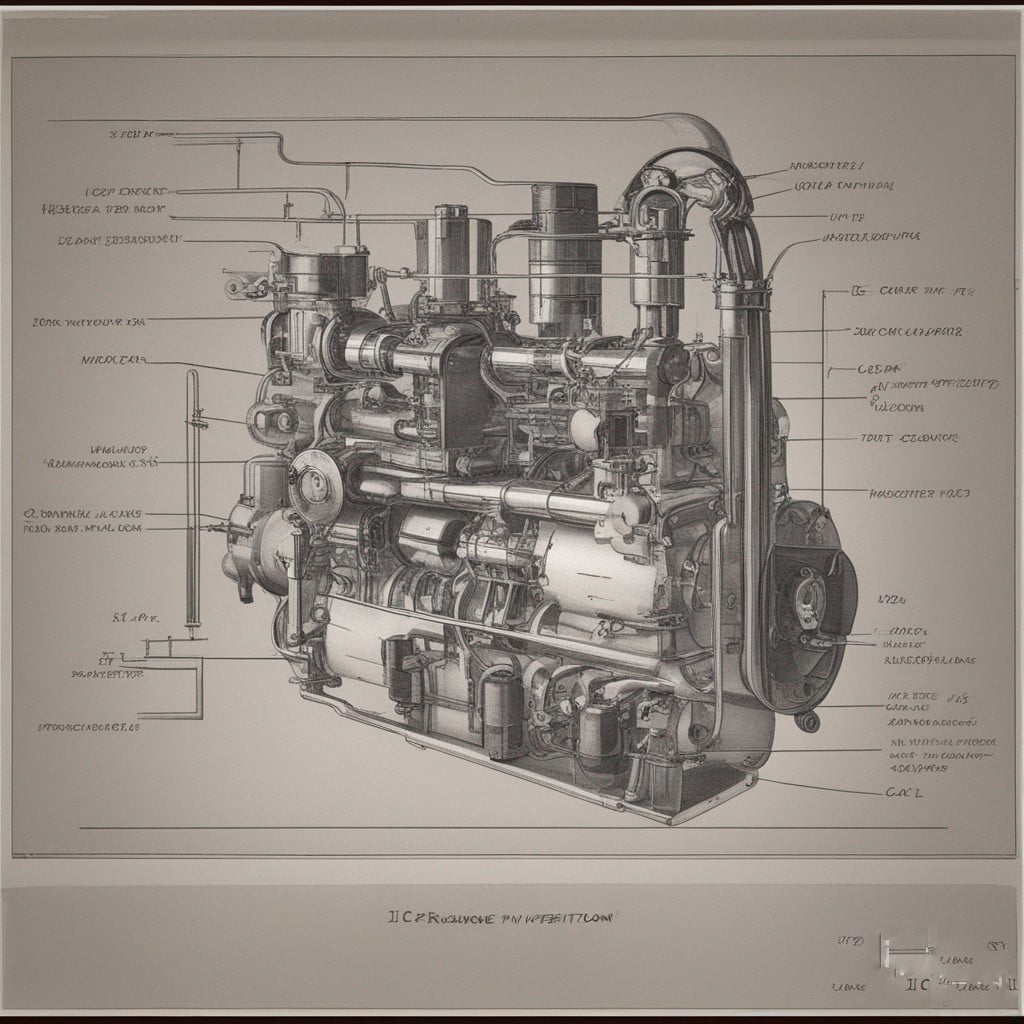

|

| Modern Engine |

Different Perspectives:

- The future of IC engines is not a binary choice between complete elimination and continued dominance. A nuanced understanding acknowledges that IC engines will likely coexist with electric vehicles and other emerging technologies in a diverse transportation landscape.

- Sustainability considerations extend beyond tailpipe emissions. The entire life cycle of an engine, including resource extraction, manufacturing, and disposal, needs to be factored into sustainability assessments.

- The social and economic implications of transitioning away from IC engines require careful consideration. Millions of jobs are tied to the automotive industry, and ensuring a just transition that protects livelihoods is crucial.

By acknowledging these diverse perspectives and ongoing research efforts, we can navigate a path towards a more sustainable future where IC engines, if they continue to play a role, operate with greater efficiency, lower emissions, and responsible use of resources.

References:

- “Homogeneous Charge Compression Ignition (HCCI) Engines: Mixture Formation and Control” by SAE International

- “Emission Control Technologies for Internal Combustion Engines” by Elsevier

- “Electric Vehicles and Hybrid Electric Vehicles: Current Status and Future Trends” by Journal of Power Sources

The contributions of these visionary scientists and engineers have paved the way for the remarkable advancements we witness in modern IC engines. Their relentless pursuit of knowledge and innovation has shaped the evolution of transportation and industry, leaving an indelible mark on human progress.

Importance of the Internal Combustion Engine:

The internal combustion engine has had a profound impact on society. Here are a few reasons why it is of great importance:

Transportation:

As we know the invention of the internal combustion engine revolutionized transportation. The development of automobiles, motorcycles, airplanes, and ships, provided faster and more efficient means of travel and transport of goods.

Industrial Growth:

The internal combustion engine powered the Industrial Revolution by driving factory machinery and equipment. It replaced manual labor with machines, leading to increased productivity and the expansion of industries.

Accessibility:

The availability of affordable vehicles powered by internal combustion engines made transportation accessible to the masses. It brought about societal changes, such as urbanization and the freedom of mobility.

Economic Impact:

The internal combustion engine’s influence on industries, including automotive, manufacturing, and oil, has had a significant economic impact worldwide. It created jobs, stimulated economic

growth, and shaped global trade.

Comparing Two-Stroke and Four-Stroke Engines:

The choice between two-stroke and four-stroke engines depends on factors like efficiency, power output, emissions, and intended use. While two-stroke engines are simpler, they generally produce more pollution and are less fuel-efficient compared to their four-stroke counterparts.

| Feature | Two-Stroke Engine | Four-Stroke Engine |

|---|---|---|

| Operational Cycle | Completes a power cycle in two strokes (one upstroke and one downstroke) | Completes a power cycle in four strokes (intake, compression, power, exhaust) |

| Combustion | Occurs every crankshaft revolution | Occurs every two crankshaft revolutions |

| Processes per Stroke | Intake, compression, combustion, and exhaust combined in two strokes | Each process (intake, compression, combustion, exhaust) completed in a separate stroke |

| Efficiency | Generally less fuel-efficient | Typically more fuel-efficient |

| Reason for Efficiency | Shorter time for combustion and less effective exhaust scavenging | Separate strokes for each phase allow better control of combustion and exhaust processes |

| Power Output | Higher power output for size due to shorter time between power strokes | Power output over a longer time for smoother delivery |

| Applications | Motorcycles, chainsaws (high power-to-weight ratio needed) | Cars, trucks, machinery (balance of power and efficiency) |

| Emissions | Higher emissions due to incomplete combustion | Generally fewer pollutants due to better combustion control |

| Lubrication | Oil mixed with fuel, leading to oil consumption and emissions | Separate oil system for cleaner combustion and lower oil consumption |

| Complexity | Simpler design with fewer moving parts | More complex with separate strokes |

| Manufacturing & Maintenance | Easier to manufacture and maintain | Higher manufacturing and maintenance costs |

In Conclusion:

The discovery and development of Internal Combustion Engines have revolutionized the way we live, work, and travel. From the early experiments of Otto and Lenoir to the modern marvels of engineering, IC engines have evolved and adapted to meet the changing demands of society. As we move towards a more sustainable future, the legacy of IC engines continues to drive innovation and shape the trajectory of transportation and industrial progress.

Also, Check out interesting blogs-