Introduction: Why the Corliss Steam Engine Mattered

The Corliss steam engine is often described as the game-changing engine of the Industrial Revolution. While steam engines had already powered factories, mines, and railroads for decades, George Henry Corliss’s design introduced an unprecedented leap in efficiency and reliability.

Unlike earlier models, which wasted vast amounts of steam, the Corliss engine used a sophisticated system of rotary valves and automatic governors. This innovation allowed factories to save fuel, produce more power, and operate machinery with greater precision. At the 1851 Great Exhibition in London, observers hailed it as one of the most important Industrial Revolution inventions, cementing Corliss’s name in history.

In short, the Corliss engine wasn’t just another machine—it was the beating heart of 19th-century industry, powering everything from textile mills to printing presses and setting the standard for modern steam engineering.

George Henry Corliss – The Inventor Behind the Machine

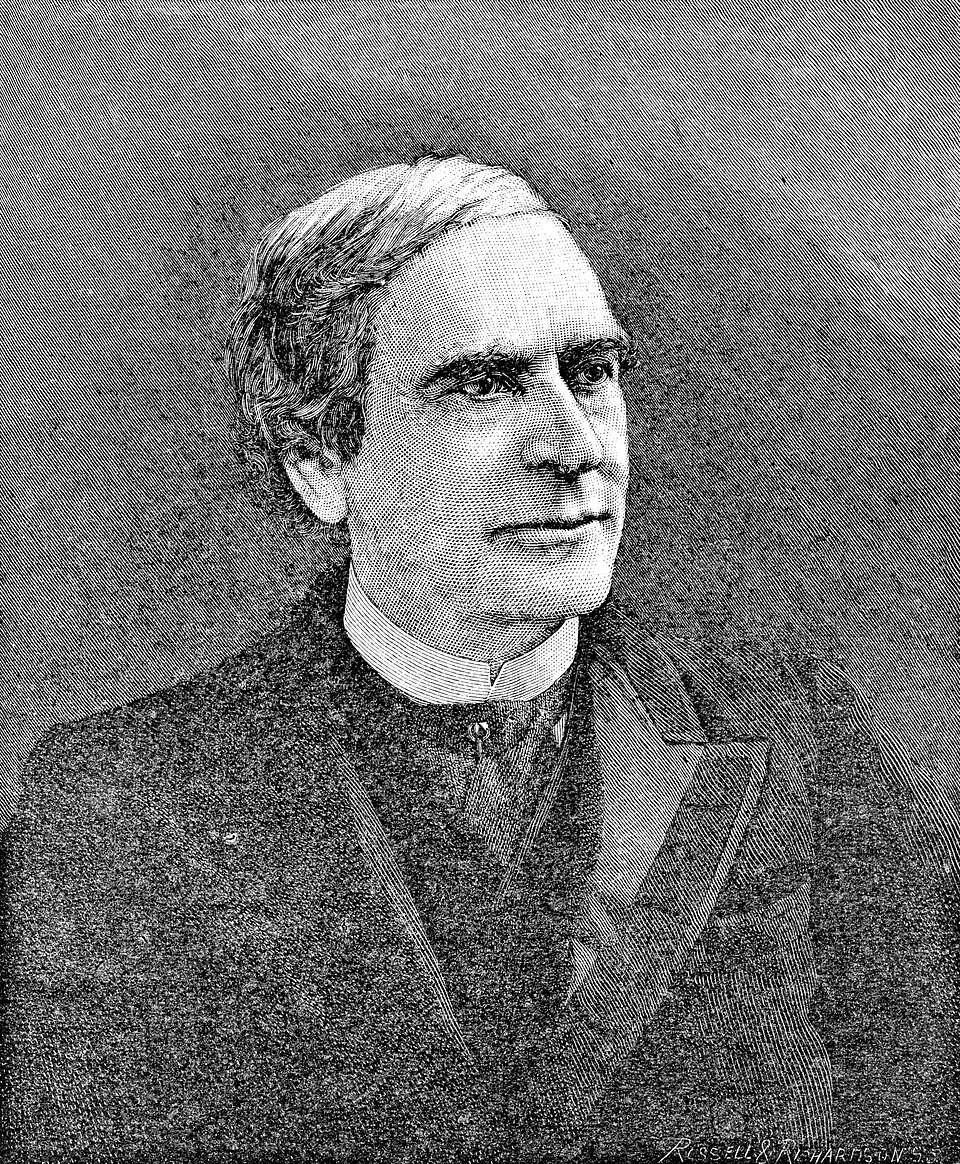

The genius behind this revolutionary engine was George Henry Corliss (1817–1888), an American inventor and businessman from Easton, New York. Unlike many inventors of his era who came from scientific or engineering backgrounds, Corliss began his career in trade and business. His entrepreneurial mindset pushed him to focus not just on invention, but also on practical applications that could transform industries.

In the 1840s, Corliss turned his attention to the history of steam engines, studying James Watt’s pioneering designs and later modifications. He recognized that while Watt’s engines marked a huge advancement, they were still highly inefficient—losing energy through poorly controlled steam distribution.

Corliss’s invention was unique because he approached the problem as both a businessman and an engineer. He envisioned an engine that factories could rely on for consistent performance, lower operating costs, and higher output. This combination of technical insight and commercial ambition set him apart from his contemporaries.

By the mid-19th century, Corliss had founded the Corliss Steam Engine Works in Providence, Rhode Island, where his George Corliss invention began reshaping industry across America and Europe.

Steam Power Before Corliss

To understand why the Corliss engine was such a breakthrough, we first need to look at the history of steam engines before 1849.

The earliest practical steam engines emerged in the early 18th century. Thomas Newcomen’s atmospheric engine (1712) was primarily used for pumping water out of mines. It was groundbreaking for its time, but extremely inefficient—burning large amounts of coal for relatively little output.

Later in the century, James Watt revolutionized steam power with his separate condenser design (1769 patent), which significantly reduced wasted energy compared to Newcomen’s model. Watt’s engine could drive rotary motion, making it useful for powering textile mills, flour mills, breweries, and ironworks. This innovation spread rapidly across Britain and Europe, becoming one of the defining technologies of the Industrial Revolution.

However, Watt’s steam engines—and the designs that followed—still suffered from fundamental flaws:

- Low efficiency – Steam distribution relied on slide valves, which leaked heat and wasted power.

- High fuel consumption – Factories often burned tons of coal daily to keep engines running, driving up operating costs.

- Uneven speed control – The centrifugal governor helped regulate output, but sudden changes in industrial loads (like starting or stopping looms) still caused dangerous fluctuations.

As the 19th century progressed, industries became larger and more mechanized. Textile mills required synchronized looms, printing presses demanded precise timing, and ironworks relied on steady power for rolling mills. The limitations of Watt’s design created bottlenecks: machines stalled, production slowed, and fuel bills soared.

By the 1840s, the history of steam engines had reached a critical juncture. Industry needed a machine that combined power with efficiency, precision, and reliability. That demand created the perfect opportunity for George Corliss to deliver a revolutionary solution.

The Invention of the Corliss Steam Engine (1849 Patent)

In 1849, George Henry Corliss secured a U.S. patent for a machine that would transform industry: the Corliss steam engine. At first, Corliss was not a trained engineer—he was a businessman with a keen eye for mechanical improvement. But his determination to enhance steam power efficiency led to one of the century’s most celebrated innovations.

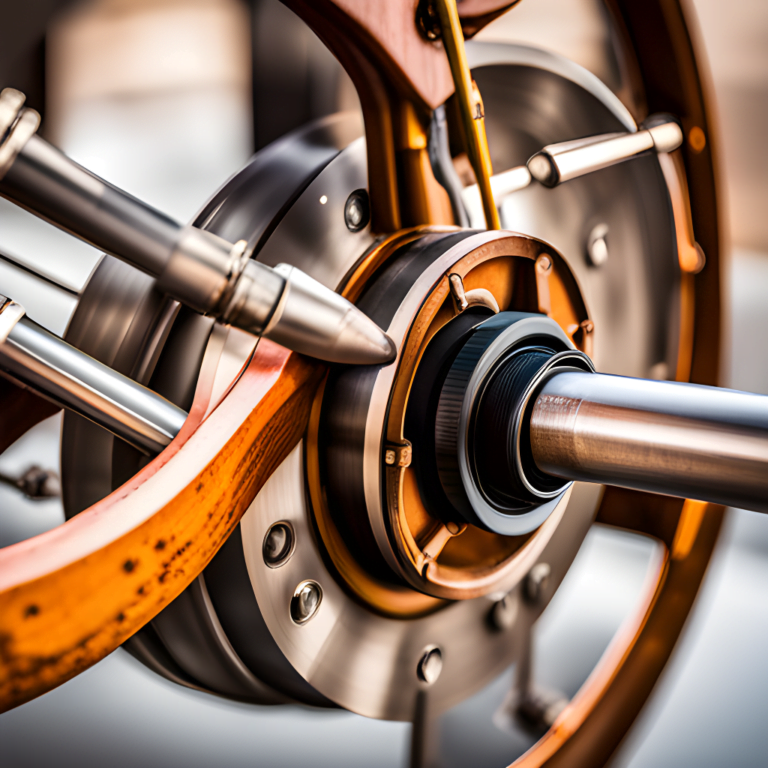

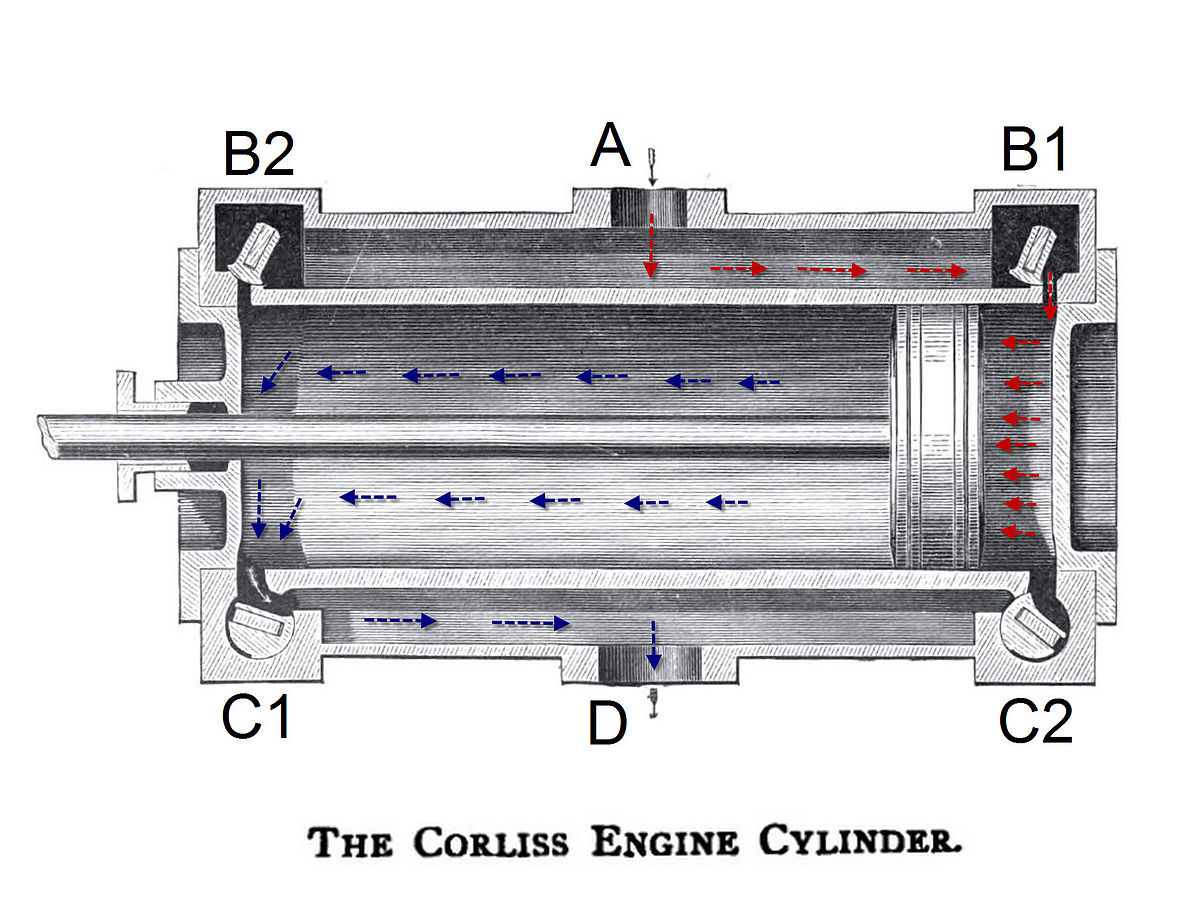

What set the George Corliss invention apart was its radical new valve gear system. Traditional steam engines used simple slide valves, which wasted energy by admitting and releasing steam inefficiently. Corliss replaced them with a rotary valve system that separately controlled steam admission and exhaust, allowing for far more precise distribution.

Key innovations of the 1849 patent included:

- Rotary valves – Reduced friction, wear, and leakage compared to slide valves, ensuring smoother, longer-lasting operation.

- Variable cut-off mechanism – Automatically adjusted how much steam entered the cylinder depending on load conditions. This meant the engine never used more steam than necessary, drastically improving Corliss engine efficiency.

- Independent intake and exhaust control – Allowed for optimal steam expansion, conserving heat energy and reducing waste.

These improvements enabled the Corliss engine to consume 30% less coal than conventional engines while maintaining remarkably steady speeds, even under fluctuating industrial loads. For manufacturers, this meant lower fuel bills, reduced downtime, and higher productivity.

The Corliss steam engine gained worldwide recognition at the 1851 Great Exhibition in London, where it was hailed as one of the most advanced machines of its age. Industrialists quickly realized that adopting the George Corliss invention would give them a competitive advantage. Textile mills, ironworks, and other factories across the U.S. and Europe began installing Corliss engines, marking the start of a new era in industrial power.

Technical Design & Working Principle

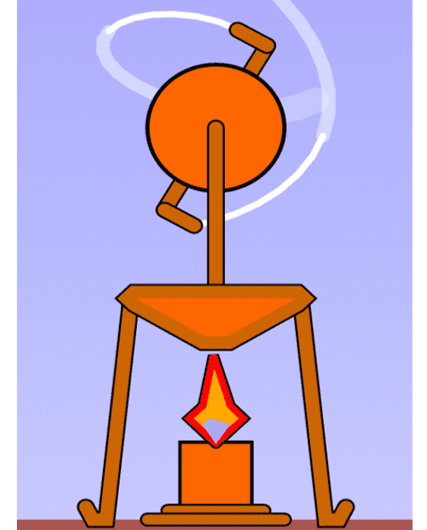

The Corliss steam engine stood apart from earlier steam engines because of its innovative mechanical design. Its parts worked together in a way that maximized both power and precision:

- Rotary Valve System – Instead of the sliding valves used in Watt’s engine, Corliss employed a rotary valve system. This allowed steam to enter and exhaust with minimal resistance, reducing friction and wear on the parts while improving control over steam timing.

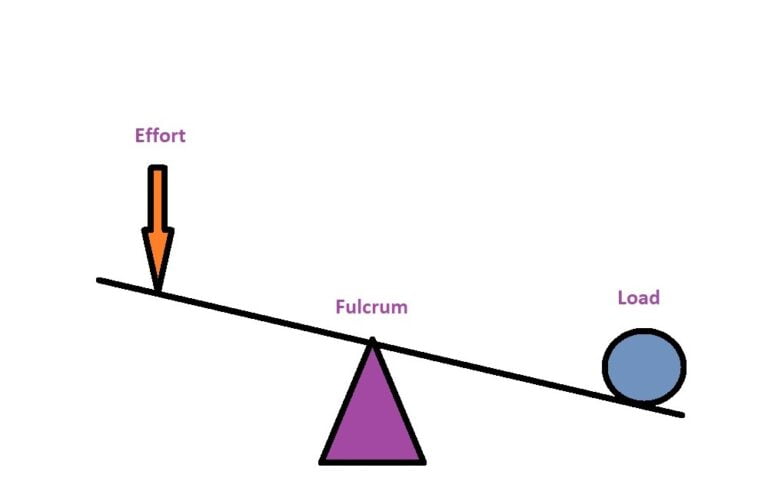

- Governor for Speed Control – A centrifugal governor was directly connected to the valve system. This meant that whenever the engine’s load increased or decreased, the governor automatically adjusted the steam cut-off, keeping the speed nearly constant. This feature was crucial in factories where machines demanded steady motion.

- High-Pressure Efficiency – Corliss engines were designed to operate effectively at higher steam pressures. Combined with the rotary valve system, this allowed for more complete expansion of steam, extracting greater energy before release.

Comparison with Watt’s Engine

- Watt’s engines used sliding valves, which were prone to steam leakage and uneven timing.

- Watt’s governor controlled speed indirectly and lacked precision, often resulting in fluctuations.

- The Corliss design offered higher fuel economy, smoother operation, and longer-lasting components.

If you visualize it, Watt’s engine looked like a workhorse dragging a heavy load, while the Corliss engine was like a finely tuned machine tool—efficient, responsive, and reliable.

Efficiency Breakthrough – Why It Was Revolutionary

The defining advantage of the Corliss system was its remarkable efficiency. Studies at the time showed that the Corliss engine consumed up to 30% less fuel than conventional Watt-type engines. For coal-dependent factories, this represented enormous savings in operating costs.

More importantly, the Corliss design introduced the ability to maintain a constant speed regardless of load variations. In textile mills, printing houses, and machine shops, this was critical—precision in production meant fewer defective products, faster output, and smoother integration of new machinery.

Key breakthroughs included:

- Fuel Savings – Lower coal consumption meant industries could cut costs while producing more.

- Steady Speed – The automatic governor ensured that machinery like looms and presses worked without sudden stops or surges.

- Scalability – The efficiency gains allowed larger factories to run multiple machines from a single engine without reliability issues.

In the broader context of Industrial Revolution inventions, the Corliss steam engine was a true force multiplier. By lowering costs and stabilizing factory operations, it directly contributed to the rapid growth of industries across Europe and America.

In fact, some historians argue that without the Corliss engine efficiency, the explosive expansion of 19th-century manufacturing might have been far slower.

Role in the Industrial Revolution

The Corliss steam engine was more than just another machine—it became one of the most defining Industrial Revolution inventions. Factories of the mid-19th century faced challenges of high fuel costs, unreliable speed, and frequent mechanical issues with earlier engines. Corliss’s innovation addressed these problems, making steam power dependable and cost-effective.

Adoption across industries:

- Textile mills: Constant speed allowed weaving and spinning machines to run smoothly, reducing thread breakage and improving fabric quality.

- Ironworks and steel plants: With increased power and fuel efficiency, furnaces and rolling mills could produce more at lower costs.

- Printing presses: For the first time, newspapers and books could be mass-produced with consistent speed, fueling literacy and information spread.

- General manufacturing: Any industry needing steady rotary power—from flour mills to paper production—benefited from the Corliss design.

Symbol of America’s industrial might:

At the 1876 Philadelphia Centennial Exposition, Corliss showcased a massive 1,400-horsepower engine that powered nearly every exhibit in Machinery Hall. Standing 45 feet tall with flywheels 30 feet in diameter, it was viewed by thousands, including President Ulysses S. Grant. This spectacle cemented the Corliss engine as a symbol of American ingenuity and industrial leadership.

In short, the Corliss engine wasn’t just powering factories—it was powering progress, reshaping the economic and social fabric of the 19th century.

Global Spread and Legacy

The success of the Corliss steam engine quickly spread beyond American borders. By the mid-to-late 19th century, industries in Britain, France, and Germany were adopting the design to fuel their own industrial growth. Many of these countries, initially skeptical of an American invention, soon recognized that its efficiency and reliability outclassed traditional Watt-style engines.

Global industrial impact:

- Europe: Textile centers in Manchester and Lyon, as well as German ironworks, integrated Corliss engines to remain competitive.

- Colonial industries: Exported to India, Australia, and Latin America, the engines powered mills, sugar refineries, and rail workshops.

- Urban infrastructure: Some Corliss engines even found use in municipal water pumping and early electric power generation systems.

Influence on future designs:

The Corliss engine set the stage for later technological advancements. Its precise valve system and improved efficiency directly influenced the development of steam turbines, which became the backbone of 20th-century power generation. Even today, engineers studying the history of steam engines cite Corliss’s invention as a turning point that bridged early mechanical engines and modern energy systems.

Enduring legacy:

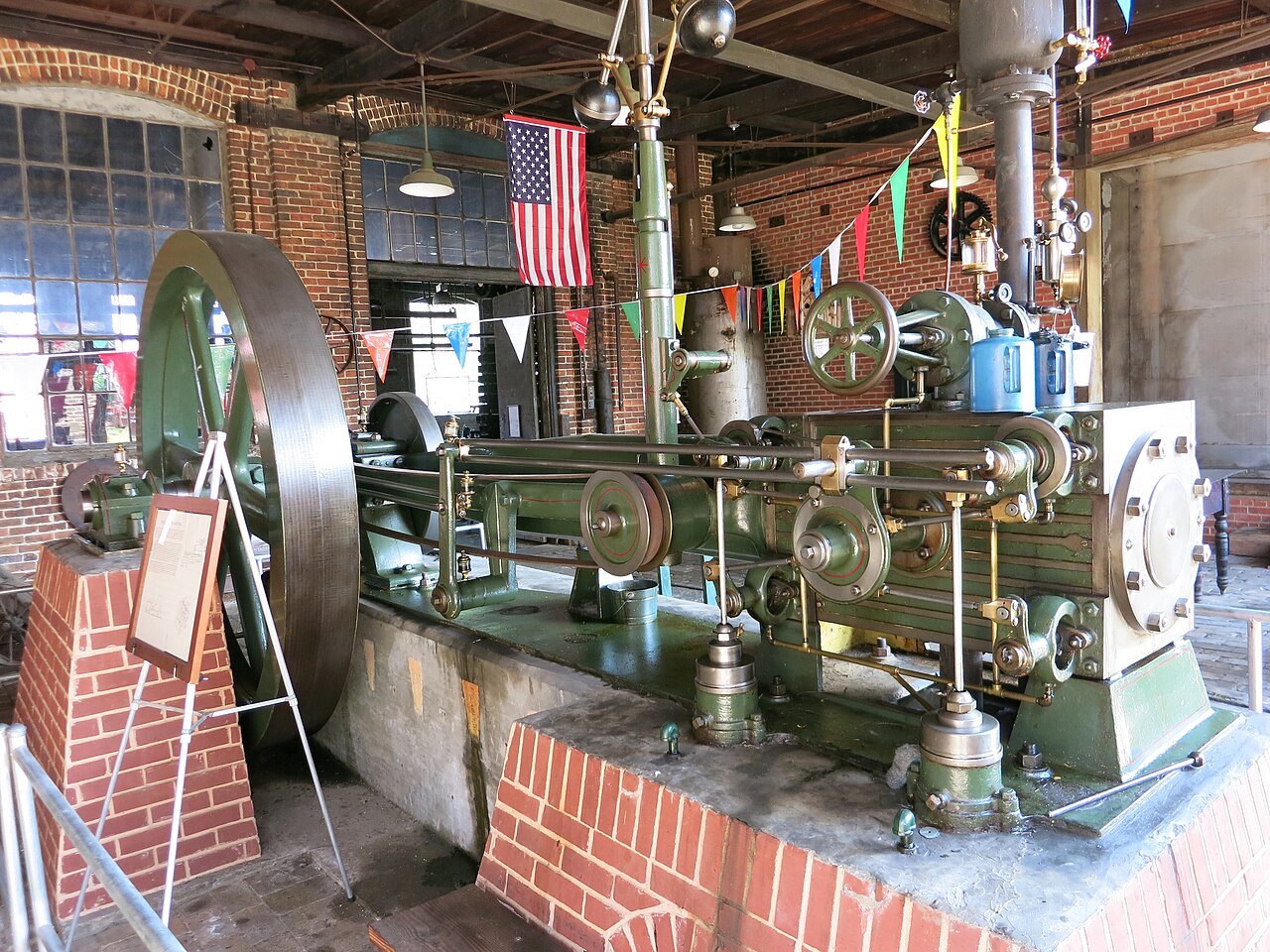

Though steam eventually gave way to electricity and internal combustion, many preserved Corliss engines still operate in museums and heritage sites, standing as mechanical monuments to the Industrial Age. They remind us how one invention can redefine global industry and reshape the future.

Decline and Historical Importance

By the late 19th and early 20th centuries, the Corliss steam engine faced competition from newer technologies. Internal combustion engines offered more compact power solutions, especially for transportation and small-scale industries. Soon after, electric motors emerged, providing cleaner, quieter, and more versatile power that could be distributed through city-wide electrical grids. As industries modernized, the once-revolutionary Corliss engine gradually declined in use.

Yet, its historical importance cannot be overstated. The Corliss engine efficiency—fuel savings of more than 30% and unprecedented speed regulation—set benchmarks for mechanical design and industrial productivity. Even as technology advanced, engineers continued to study Corliss’s valve mechanism as a masterclass in thermodynamic efficiency.

Today, many surviving engines are carefully preserved in museums and heritage sites around the world. Notable examples can be found in the Smithsonian Institution (U.S.), the Henry Ford Museum, and several European industrial museums. Restored Corliss engines are still demonstrated to the public, showing how this 19th-century invention powered the rise of modern industry.

Historians and engineers alike continue to admire the Corliss engine not just as a machine, but as a turning point in the history of industrial technology.

Conclusion – The Lasting Legacy of George Corliss

The George Corliss invention of 1849 was more than an engineering breakthrough—it was a defining moment in the story of the Industrial Revolution. By combining technical brilliance with practical efficiency, the Corliss steam engine transformed industries, accelerated production, and symbolized America’s growing industrial strength.

Its legacy lies not only in the factories it powered but also in the inspiration it provided for future engineers and inventors. The Corliss engine demonstrated that efficiency and precision could change the trajectory of entire economies. Without it, the pace of industrialization in the 19th century would have been dramatically slower.

Even today, the Corliss engine remains a shining example of how innovation can reshape the world. George Corliss proved that one visionary invention can spark a wave of progress, leaving a lasting impact on technology and society alike.

💡 If you found the story of the Corliss Steam Engine fascinating, you might also enjoy exploring other groundbreaking inventions in history. Check out these articles: