Introduction

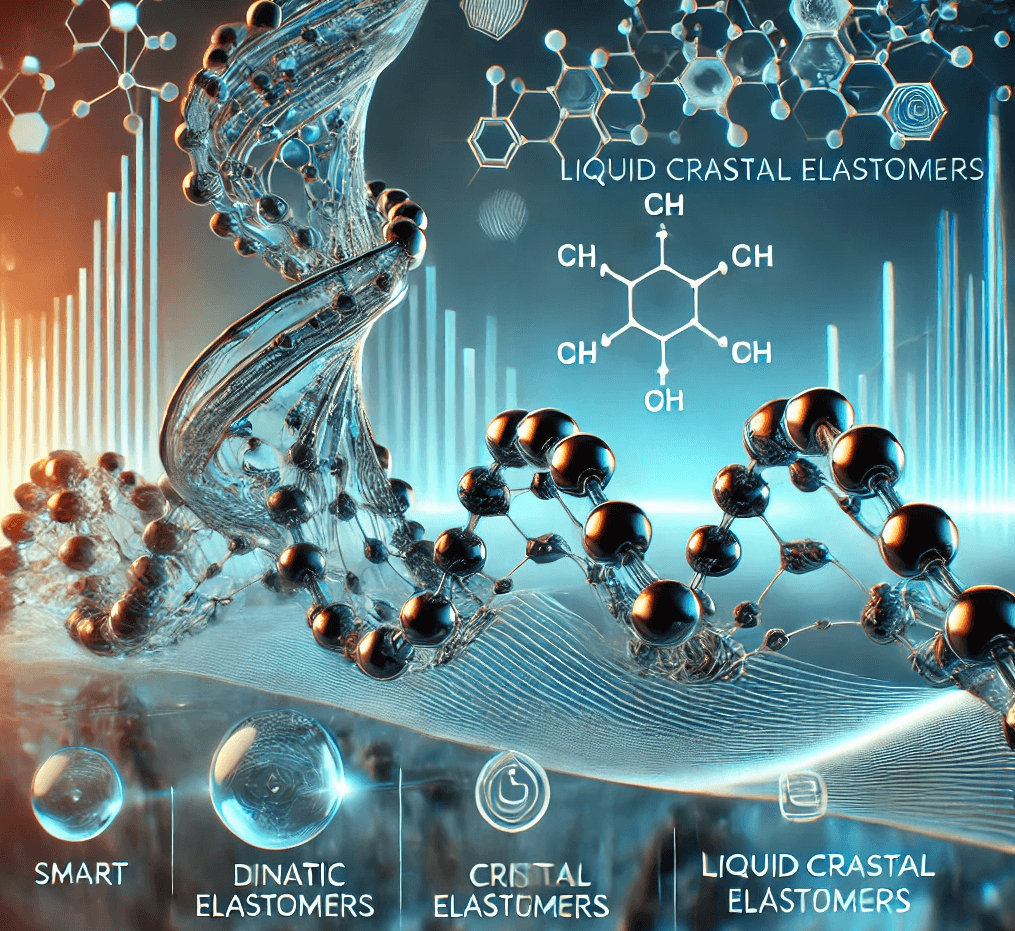

In the rapidly evolving world of material science, liquid crystal elastomers (LCEs) have emerged as a groundbreaking innovation. Combining the unique properties of liquid crystals and elastomers, these materials are redefining what’s possible in smart and adaptive technologies.

Liquid crystal elastomers are soft, flexible materials that can change shape, adapt, and respond to external stimuli such as heat, light, and electric fields. This ability to “actuate” or move in response to environmental changes makes them incredibly versatile. Imagine a material that can heal itself, morph into different shapes, or even perform mechanical tasks without traditional motors or gears.

The potential applications of liquid crystalline elastomers are vast and transformative. In biomedical engineering, they are being explored for use in artificial muscles and drug delivery systems. In soft robotics, they enable the creation of robots that can move with the grace and flexibility of living organisms. In smart textiles, they pave the way for clothing that adapts to temperature or movement, offering unprecedented comfort and functionality.

What sets liquid crystal elastomer properties apart is their ability to bridge the gap between rigid and soft materials, offering both strength and adaptability. As researchers continue to unlock their potential, LCEs are poised to revolutionize industries and redefine the future of smart materials.

What Are Liquid Crystal Elastomers?

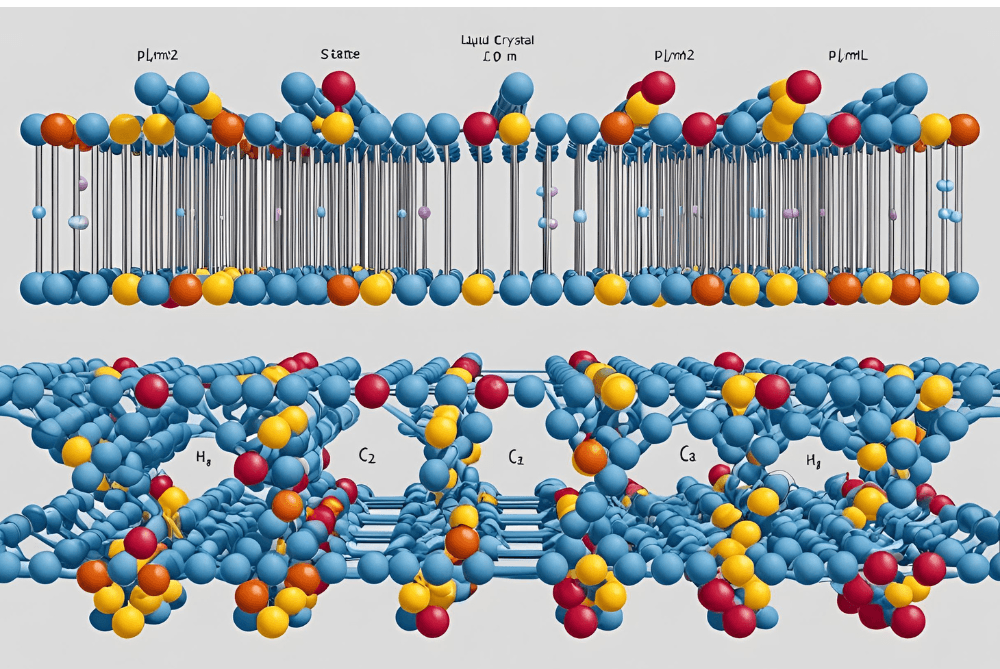

At their core, liquid crystal elastomers (LCEs) are a hybrid material that combines the molecular order of liquid crystals with the elasticity of elastomers. This unique combination gives them extraordinary properties that traditional materials simply cannot match.

Scientific Explanation

LCEs are composed of polymer chains embedded with liquid crystal molecules. These liquid crystal molecules can align in specific directions, giving the material a degree of molecular order. When exposed to external stimuli like heat, light, or electric fields, the alignment of these molecules changes, causing the material to deform or change shape. This process is reversible, meaning the material can return to its original state once the stimulus is removed.

Physical Characteristics

- Self-Healing: LCEs can repair minor damage on their own, thanks to the dynamic nature of their polymer networks.

- Flexibility: Unlike rigid materials, LCEs are soft and stretchable, making them ideal for applications requiring movement and adaptability.

- Responsiveness: LCEs can react to environmental changes in real-time, making them highly functional in dynamic settings.

Comparison with Traditional Elastomers

Traditional elastomers, like rubber, are flexible but lack the ability to respond to external stimuli. Liquid crystal elastomers, on the other hand, are not only flexible but also “smart.” They can be programmed to perform specific actions, such as bending, twisting, or expanding, when triggered by heat, light, or other stimuli. This makes them far more advanced and versatile than conventional materials.

Real-World Analogy

Think of LCEs as smart rubber that can “remember” its shape and change when activated. For example, a flat sheet of LCE could curl into a tube when exposed to heat, then flatten again when cooled. This ability to transform on demand opens up endless possibilities for innovation.

How Do Liquid Crystal Elastomers Work?

Liquid crystal elastomers (LCEs) are fascinating materials that bridge the gap between the molecular order of liquid crystals and the elasticity of polymers. But how exactly do they work, and what makes them so responsive to external stimuli? Let’s dive into the science behind these smart materials and explore their transformative potential.

Molecular Alignment Changes: The Heart of LCE Functionality

At the core of liquid crystal elastomers is their unique molecular structure. LCEs are made up of polymer chains embedded with liquid crystal molecules. These liquid crystal molecules can align in specific directions, creating a degree of molecular order within the material.

When an external stimulus—such as heat, light, or an electric field—is applied, the alignment of these liquid crystal molecules changes. This rearrangement disrupts the material’s internal structure, causing it to deform or change shape. Once the stimulus is removed, the molecules return to their original alignment, and the material reverts to its initial state. This reversible process is what makes LCEs so versatile and functional.

Response to External Triggers

The ability of liquid crystal elastomers to respond to external triggers is what sets them apart from traditional materials. Here’s how they react to different stimuli:

- Heat Activation

Heat is one of the most common triggers for LCEs. When exposed to heat, the liquid crystal molecules within the elastomer rearrange, causing the material to contract, expand, or change shape.

Applications:

- Biomedical Implants: LCEs can be used to create artificial muscles that contract and expand in response to body heat.

- Smart Clothing: Fabrics embedded with LCEs can adapt to temperature changes, providing better insulation or ventilation.

- Light-Triggered Changes

LCEs can also respond to light, particularly UV or visible light. When exposed to light, the liquid crystal molecules absorb energy and realign, causing the material to deform.

Applications:

- Optical Devices: LCEs can be used in lenses or filters that change shape or opacity in response to light.

- Robotics: Light-activated LCEs enable the creation of soft robots that can move or perform tasks when exposed to specific wavelengths of light.

- Electric Field Activation

Electric fields can also trigger changes in LCEs. When an electric field is applied, the liquid crystal molecules realign, causing the material to deform.

Applications:

- Flexible Electronics: LCEs can be integrated into devices that change shape or function in response to electrical signals.

- Soft Robotics: Electric field-activated LCEs are ideal for creating robots that can perform precise movements or tasks.

Key Examples of LCE Transformations

The ability of liquid crystal elastomers to transform in response to external stimuli has led to some groundbreaking applications:

- Soft Actuators (Artificial Muscles)

LCEs can mimic the behavior of natural muscles by contracting and expanding in response to stimuli. For example, a strip of LCE can be programmed to curl when heated and straighten when cooled, making it ideal for use in artificial muscles or soft robotics.

- Shape-Morphing Surfaces

LCEs can be used to create surfaces that change shape in response to environmental conditions. For instance, a flat sheet of LCE could morph into a 3D structure when exposed to light or heat. This capability has exciting applications in adaptive architecture, where materials could adjust to optimize energy efficiency or structural integrity.

- Self-Healing Materials

Thanks to their dynamic polymer networks, LCEs can repair minor damage on their own. This self-healing property makes them ideal for use in wearable technology or medical devices, where durability and longevity are critical.

How to Prepare Liquid Crystal Elastomers?

The synthesis of liquid crystal elastomers (LCEs) is a fascinating process that combines chemistry, material science, and engineering. By carefully controlling the molecular structure and alignment, researchers can create materials with unique properties like shape-changing, self-healing, and responsiveness to external stimuli. Here’s a step-by-step guide to preparing LCEs, along with emerging techniques like 3D printing and the challenges involved in their production.

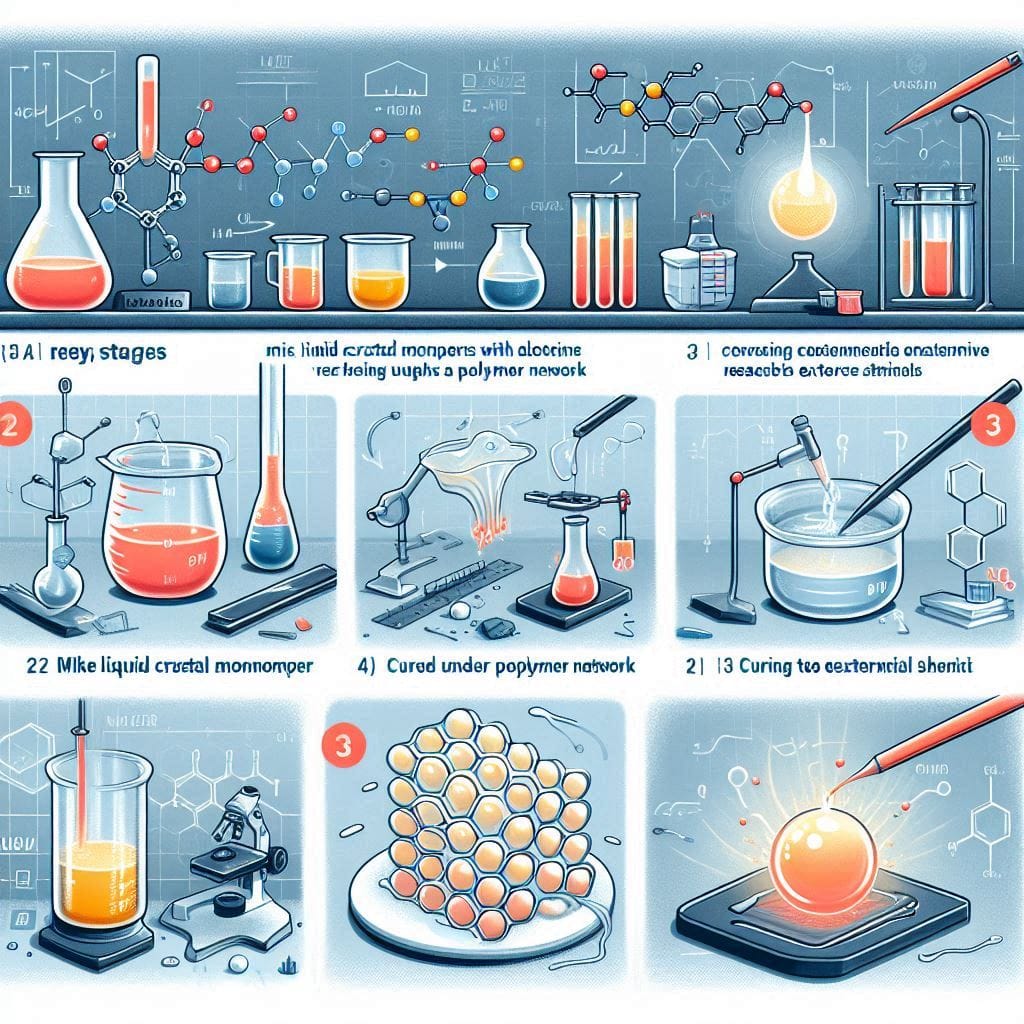

Step-by-Step Synthesis Process

- Selecting Liquid Crystal Monomers

The first step in preparing liquid crystalline elastomers is selecting the right liquid crystal monomers. These monomers are the building blocks of the material and determine its final properties.

Key Considerations:

- The monomers should have liquid crystal phases, meaning they can align in specific directions.

- They must be compatible with the polymer matrix to ensure proper crosslinking.

- Common choices include acrylate-based or siloxane-based monomers, which offer flexibility and responsiveness.

- Crosslinking Process

Once the monomers are selected, they are chemically bonded to create the elastomer structure. This process, known as crosslinking, involves forming strong covalent bonds between the polymer chains.

How It Works:

- The monomers are mixed with a crosslinking agent and a catalyst.

- The mixture is heated or exposed to UV light to initiate the polymerization reaction.

- As the reaction proceeds, the polymer chains form a network, giving the material its elastic properties.

Importance of Crosslinking:

- Determines the material’s mechanical strength and flexibility.

- Influences the material’s ability to return to its original shape after deformation.

- Aligning Liquid Crystals for Programmable Shape Changes

The final step is aligning the liquid crystal molecules within the polymer network. This alignment is crucial for enabling the material’s programmable shape changes.

Alignment Techniques:

- Mechanical Stretching: The material is stretched in a specific direction, causing the liquid crystal molecules to align along the stretch axis.

- Magnetic or Electric Fields: External fields can be used to align the molecules in a desired orientation.

- Surface Anchoring: The material is placed on a surface with a specific pattern, which guides the alignment of the liquid crystals.

Result:

- The aligned liquid crystals allow the material to deform in a controlled manner when exposed to stimuli like heat, light, or electric fields.

3D Printing of LCEs: Emerging Manufacturing Techniques

One of the most exciting advancements in LCE production is the use of 3D printing. This technique allows for the creation of complex, customized structures with precise control over material properties.

How It Works:

- LCEs are prepared as a printable ink, often by mixing liquid crystal monomers with a photoinitiator.

- The ink is deposited layer by layer using a 3D printer, with UV light used to cure each layer and create the crosslinked structure.

- The alignment of liquid crystals can be controlled during printing by applying mechanical stress or using patterned surfaces.

Advantages of 3D Printing:

- Enables the creation of intricate geometries that are difficult to achieve with traditional methods.

- Allows for customization of material properties, such as stiffness and responsiveness.

- Reduces material waste and production time.

Challenges in Production

Despite their potential, the production of liquid crystal elastomers faces several challenges:

- Cost: The synthesis of LCEs often requires expensive raw materials and specialized equipment, making large-scale production costly.

- Material Stability: LCEs can degrade over time when exposed to harsh environmental conditions, such as high temperatures or UV radiation.

- Large-Scale Manufacturing: Scaling up production while maintaining consistent quality and alignment of liquid crystals remains a significant hurdle.

Researchers are actively working to address these challenges by developing more cost-effective synthesis methods, improving material stability, and optimizing manufacturing processes.

Key Applications of Liquid Crystal Elastomers

Liquid crystal elastomers (LCEs) are revolutionizing a wide range of industries, from healthcare to robotics and beyond. Their unique properties—such as shape-changing, self-healing, and responsiveness to external stimuli—make them ideal for cutting-edge applications. Here’s a closer look at how LCEs are being used today and their potential for the future.

Biomedical Applications

- Artificial Muscles

LCEs are being used to create artificial muscles that mimic the behavior of biological tissues. These materials can contract and expand in response to stimuli, making them ideal for use in prosthetics and medical devices.

- Example: A strip of LCE can be programmed to curl when heated, mimicking the movement of a natural muscle.

- Self-Healing Implants

LCEs’ self-healing properties make them perfect for use in adaptive implants. These materials can repair minor damage on their own, reducing the need for replacement surgeries.

- Example: LCE-based implants that adapt to the body’s movements and promote faster wound healing.

- Wearable Sensors

LCEs are being integrated into smart textiles that respond to temperature changes, providing real-time feedback on the wearer’s health.

- Example: A wearable sensor that changes color or shape in response to body temperature, alerting the wearer to potential health issues.

Soft Robotics

- Programmable Actuators

LCEs are being used to create soft actuators that can perform complex movements, such as bending, twisting, or gripping.

- Example: A robotic arm made from LCEs that can gently pick up delicate objects without damaging them.

- Flexible Electronics

LCEs are being integrated into flexible electronics, such as bendable screens and foldable devices.

- Example: A smartphone screen that can bend or fold without breaking, thanks to LCE-based materials.

Smart Textiles & Wearables

- Temperature-Responsive Clothing

LCEs are being used to create smart clothing that adapts to temperature changes, providing better insulation or ventilation.

- Example: A jacket that becomes thicker in cold weather and thinner in warm weather, thanks to LCE-based fibers.

- Shape-Morphing Shoes

LCEs are being used to create smart footwear that adapts to different surfaces, providing better comfort and support.

- Example: Shoes that change shape to provide extra cushioning when walking on hard surfaces.

Future Applications

- Aerospace & Architecture

LCEs could be used to create self-deploying structures, such as solar panels or antennas that unfold in space.

- Energy Harvesting

LCEs could be used to create smart coatings that change properties in response to external stimuli, improving energy efficiency.

Advantages and Challenges of Liquid Crystal Elastomers

Liquid crystal elastomers (LCEs) are revolutionizing the field of smart materials with their unique properties and adaptability. However, like any emerging technology, they come with both advantages and challenges. Understanding these can help researchers and industries harness their potential while addressing limitations.

Advantages of LCEs

- High Flexibility and Durability

LCEs are incredibly flexible and durable, making them ideal for applications in soft robotics and biomedicine. Their ability to withstand repeated deformation without losing functionality sets them apart from traditional materials.

- Example: In soft robotics, LCEs can mimic the flexibility of natural muscles, enabling robots to perform delicate tasks.

- Programmable Properties

One of the most exciting features of liquid crystal elastomers is their programmability. By controlling the alignment of liquid crystal molecules during synthesis, researchers can tailor the material’s response to specific stimuli, such as heat, light, or electric fields.

- Example: LCEs can be programmed to change shape in response to body temperature, making them ideal for smart textiles and wearable sensors.

- Lightweight and Energy-Efficient

LCEs are lightweight and require minimal energy to operate, making them highly efficient for use in wearables and robotics. This energy efficiency reduces power consumption and extends the lifespan of devices.

- Example: LCE-based actuators in robotics consume less power compared to traditional motors, making them ideal for portable and battery-operated devices.

Challenges of LCEs

- Complex Manufacturing Process

The synthesis of LCEs involves multiple steps, including monomer selection, crosslinking, and alignment of liquid crystals. This complexity makes it difficult to scale up production for commercial use.

- Solution: Advances in 3D printing and automated manufacturing techniques are helping to streamline the process.

- Material Stability Issues

LCEs can degrade under extreme conditions, such as high temperatures or prolonged exposure to UV light. This limits their use in harsh environments.

- Solution: Researchers are developing more stable formulations by incorporating protective coatings or additives.

- High Cost

The production of LCEs is still expensive due to the cost of raw materials and specialized equipment. This high cost is a barrier to mass adoption.

- Solution: Economies of scale and advancements in material science are expected to reduce costs over time.

The Future of Liquid Crystal Elastomers

The future of liquid crystal elastomers (LCEs) is incredibly promising, with advancements in technology and research paving the way for groundbreaking applications. Here’s a glimpse into what lies ahead:

Advancements in 3D Printing of LCEs

3D printing is revolutionizing the production of LCEs, enabling the creation of complex, customized structures with precise control over material properties.

- Customization: 3D printing allows researchers to design LCEs with specific shapes, stiffness, and responsiveness for targeted applications.

- Example: 3D-printed LCE actuators for soft robotics that can perform intricate movements.

Integration with Artificial Intelligence (AI)

The integration of LCEs with artificial intelligence (AI) is opening up new possibilities for adaptive materials.

- AI-Controlled Adaptive Surfaces: AI algorithms can predict and control how LCEs respond to stimuli, enabling real-time adaptation.

- Example: Smart windows that adjust their opacity based on weather conditions, controlled by AI.

Breakthrough Research Areas

- Self-Repairing and Self-Assembling Materials

Researchers are exploring LCEs that can repair themselves or assemble into complex structures without external intervention.

- Example: Self-healing LCE coatings for electronic devices that repair cracks automatically.

- AI-Controlled Adaptive Surfaces

LCEs combined with AI could create surfaces that adapt to environmental changes in real-time.

- Example: Adaptive building facades that optimize insulation based on temperature and humidity.

Market Growth Potential

The adoption of LCEs is expected to grow rapidly in fields like medicine, robotics, and consumer technology.

- Medicine: LCE-based implants and wearable sensors are poised to transform healthcare.

- Robotics: Soft robotics powered by LCEs will enable safer and more efficient human-robot interactions.

- Consumer Tech: Smart textiles and flexible electronics will become more accessible to consumers.

Conclusion

Liquid crystal elastomers (LCEs) are at the forefront of material science, offering unparalleled flexibility, programmability, and responsiveness. From artificial muscles in soft robotics to self-healing implants in biomedicine, LCEs are unlocking new possibilities across industries.

As advancements in 3D printing and AI integration continue, the potential applications of LCEs are only limited by our imagination. With rapid progress in research and development, these materials are set to revolutionize fields like medicine, robotics, and consumer technology.

Stay tuned for the latest breakthroughs in liquid crystal elastomers—this is just the beginning of a smarter, more adaptive future!

Related Reads You Might Find Interesting:

- 🔄 Shape-Memory Polymers – Explore materials that “remember” their shape and return to their original form when triggered.

- 🧩 Unlocking Self-Assembling Materials – Learn how self-assembling materials are revolutionizing fields from nanotechnology to construction.

- 💧 Superhydrophobic Materials – Discover how ultra-water-repellent materials are transforming surfaces and industries.

- 🖥️ Discover Programmable Matter – A deep dive into materials that can change their properties on demand, paving the way for futuristic applications.

- 🎶 The Future of Noise Cancellation: Acoustic Metamaterials – See how advanced metamaterials are redefining soundproofing and noise reduction.