Waste-to-Energy Technologies- Unveiling the Treasure Trove Within Our Trash

Imagine a world where our everyday waste wasn’t a burden, but a hidden treasure chest. Instead of overflowing landfills, what if discarded materials could be transformed into clean energy, powering our homes and businesses? This captivating vision is becoming a reality with the rise of Waste-to-Energy (WtE) technologies.

Did you know the average person throws away over 4 pounds of trash daily? That translates to a mass of global waste accumulating in landfills, posing environmental and health risks. While waste reduction remains a critical goal, WtE technologies offer a groundbreaking solution. These innovative processes unlock the hidden potential within our trash, converting it into a valuable resource – clean energy.

This blog post lets you explore the fascinating world of WtE. We’ll embark on a journey to explore various methods, including mass burn incineration, plasma gasification, and pyrolysis (including microwave pyrolysis). We’ll unveil the science behind these processes, meticulously weigh their advantages and disadvantages, and showcase real-life projects demonstrating the power of WtE to create a more sustainable future.

By the end of this exploration, you’ll gain a deeper understanding of terms like “mass burn incineration,” “plasma gasification,” and “hydrothermal carbonization” (another WtE technology you’ll discover!). This blog post is your one-stop shop for everything WtE, from the captivating science to the potential for a cleaner and more sustainable tomorrow.

Waste – A Challenge Transformed into Opportunity with WtE Technologies

Our planet faces a mounting challenge: a surplus of waste. Globally, we generate an overwhelming amount of trash each day, and overflowing landfills are a growing concern. These landfills not only consume valuable land but also contribute to methane emissions, a potent greenhouse gas. However, innovative Waste-to-Energy (WtE) technologies are emerging as powerful tools to combat this crisis and create a more sustainable future.

Waste-to-Energy (WtE): Turning Trash into Treasure

WtE technologies are a game-changer in waste management. These advanced processes don’t simply dispose of waste; they transform it into a valuable resource – clean energy. By diverting waste from landfills, WtE offers a multitude of environmental benefits:

- Reduced Landfill Dependence: WtE significantly reduces the amount of waste requiring landfilling, freeing up valuable space and minimizing the environmental impact of overflowing landfills.

- Lower Greenhouse Gas Emissions: Landfills are significant contributors to methane emissions, a greenhouse gas with a much higher warming potential than carbon dioxide. WtE diverts waste from landfills, potentially mitigating these harmful emissions.

- Clean Energy Generation: WtE technologies can generate electricity, heat, or various fuels, contributing to a cleaner and more sustainable energy mix.

A Spectrum of WtE Technologies: Exploring the Options

The world of WtE isn’t a one-size-fits-all solution. There are various WtE technologies, each with its own advantages and applications. Here’s a glimpse into the key players we’ll explore further in this blog post:

- Mass Burn Incineration: This well-established WtE technology utilizes high temperatures to convert municipal solid waste (MSW) into energy.

- Plasma Gasification: This cutting-edge approach harnesses extremely high temperatures generated by plasma torches to break down waste into usable syngas fuel.

- Pyrolysis: This thermochemical process decomposes waste materials in an oxygen-deprived environment using high temperatures. We’ll also explore a variation – microwave pyrolysis – which utilizes microwaves for efficient heating.

- Hydrothermal Carbonization (HTC): This innovative technology utilizes high-pressure and hot water to transform organic waste streams into a valuable fuel source known as hydrochar.

By understanding these diverse WtE options, we can unlock the full potential of transforming our waste challenge into a sustainable energy opportunity. Stay tuned as we delve deeper into the science behind each technology and explore real-world examples that are paving the way for a cleaner future.

Unveiling the Workhorse: Mass Burn Incineration

Mass burn incineration, the veteran of WtE technologies, has been a reliable workhorse in waste management for decades. Let’s delve into the heart of this process and explore its potential and limitations.

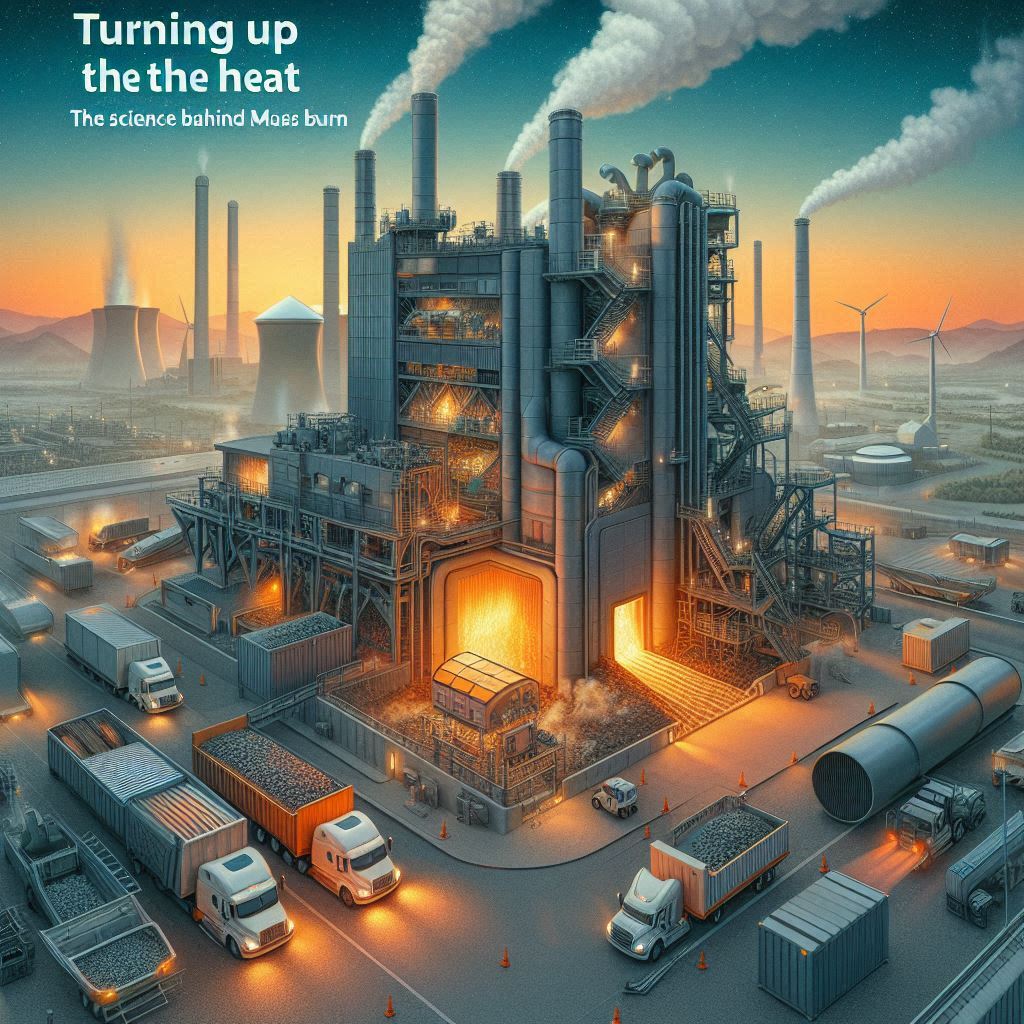

Turning Up the Heat: The Science Behind Mass Burn

Mass burn incineration utilizes a straightforward yet powerful concept – harnessing the energy stored within waste through high-temperature combustion. Municipal solid waste (MSW) , which is our everyday trash, becomes the fuel in this process. Here’s a step-by-step journey through a mass burn incineration facility:

- Waste Reception: Trucks deliver MSW, which is unloaded and undergoes pre-processing to remove bulky items or recyclables.

- Combustion Chamber: The processed waste enters a large furnace-like chamber, where it’s incinerated at high temperatures (around 800°C to 1,200°C).

- Heat Capture: The combustion process generates significant heat. Sophisticated boiler systems capture this heat and convert it into steam.

- Energy Generation: The high-pressure steam produced in the boiler drives turbines, which in turn generate electricity. This electricity can be fed back into the power grid.

- Ash Management: The incineration process leaves behind bottom ash (non-combustible materials) and fly ash (fine airborne particles). These ashes undergo rigorous treatment and disposal procedures to minimize environmental impact.

Advantages: A Potent Solution with Tangible Benefits

Mass burn incineration offers a compelling solution for waste management, boasting several key advantages:

- Significant Waste Volume Reduction: Mass burn incineration dramatically reduces the volume of waste requiring landfilling. This translates to a smaller environmental footprint and a more efficient use of valuable land.

- Reliable Energy Production: Mass burn facilities generate clean and reliable electricity, contributing to a more sustainable energy mix. This offsets reliance on fossil fuels and promotes energy independence.

- Reduced Reliance on Landfills: By diverting waste from landfills, mass burn incineration helps minimize the environmental and health risks associated with overflowing landfills.

Disadvantages: Considering the Other Side of the Coin

While a valuable tool, mass burn incineration is not without its drawbacks:

- Air Pollution Concerns: The combustion process can generate emissions, including nitrogen oxides and particulate matter. However, modern facilities employ advanced emission control systems to minimize these pollutants.

- Ash Management: The incineration process produces ash, which requires proper treatment and disposal to ensure it doesn’t pose environmental risks.

A Real-World Example: The Covanta SEMASS Facility

The Covanta SEMASS Waste-to-Energy Facility in Massachusetts, USA, exemplifies the capabilities of mass burn incineration. This state-of-the-art facility processes over 600,000 tons of waste annually, generating enough clean electricity to power over 100,000 homes. The SEMASS facility employs advanced emission control systems, including scrubbers and fabric filters, to minimize environmental impact.

By understanding both the benefits and drawbacks of mass burn incineration, we can make informed decisions about its role in a sustainable waste management strategy. In the next section, we’ll explore another innovative WtE technology: plasma gasification.

Plasma Gasification: Breaking Down Waste with Superheated Plasma Torches

Mass burn incineration, while effective, has its limitations. Enter plasma gasification, a cutting-edge WtE technology that utilizes the immense power of superheated plasma to revolutionize waste management.

Unleashing the Power of Plasma: A High-Tech Approach

Plasma gasification takes waste management to a whole new level. Imagine a high-temperature environment hotter than the sun’s surface! That’s the world of plasma, a state of matter where atoms are stripped of electrons, creating an energetic soup of charged particles. In plasma gasification, this immense heat becomes the key to unlocking the energy potential within waste.

Here’s a glimpse into the science behind this fascinating process:

- Waste Introduction: Various waste materials, including municipal solid waste (MSW) and even hazardous waste, are fed into a sealed chamber.

- Plasma Torch Ignition: Plasma torches within the chamber generate incredibly high temperatures (around 12,000°C).

- Waste Breakdown: The intense heat from the plasma torches breaks down the waste molecules into usable syngas (synthetic gas).

- Syngas Processing: The syngas, a complex mixture of gases like hydrogen, carbon monoxide, and methane, can be further processed and utilized for various energy applications.

- Slag Formation: The non-gaseous components of the waste melt at these extreme temperatures, forming a vitrified slag – a glassy material with potential applications in construction.

Advantages: Pushing the Boundaries of Waste Management

Plasma gasification offers exciting possibilities for waste management, surpassing some of the limitations of traditional incineration:

- Wider Waste Acceptance: Plasma gasification can handle a broader range of waste materials compared to incineration, including hazardous waste. This versatility makes it a powerful tool for tackling diverse waste streams.

- Potentially Lower Emissions: Plasma gasification has the potential to produce lower emissions of certain pollutants compared to incineration. However, ongoing research and development are crucial to optimize this aspect.

- Syngas Production: The syngas produced from plasma gasification is a versatile fuel source. It can be used directly for electricity generation, further processed into cleaner fuels like hydrogen, or utilized in industrial processes.

Disadvantages: A Promising Technology Under Development

While brimming with potential, plasma gasification is still a relatively new technology with some drawbacks to consider:

- High Initial Investment Costs: Setting up a plasma gasification facility requires a significant upfront investment due to the complex technology involved.

- Development Stage: Plasma gasification is still under development, and ongoing research is necessary to optimize efficiency and minimize environmental impact.

A Pioneering Example: The Edmonton Waste-to-Energy Facility

The Edmonton Waste-to-Energy Facility in Alberta, Canada, stands as a pioneering example of plasma gasification in action. This innovative facility processes over 400,000 tonnes of waste annually, converting it into clean electricity and reducing reliance on landfills. The Edmonton facility utilizes advanced pollution control systems to ensure responsible environmental practices.

Plasma gasification offers a glimpse into the future of WtE technologies. By harnessing the power of superheated plasma, we can unlock a cleaner and more sustainable approach to waste management. However, further development is needed to make this technology more cost-effective and widely adopted. In the next section, we’ll explore another innovative WtE option: pyrolysis.

Pyrolysis vs. Plasma Gasification: A Tale of Two Technologies

The world of WtE boasts a diverse arsenal of technologies, each with its strengths and weaknesses. We’ve explored the established workhorse, mass burn incineration, and the cutting-edge power of plasma gasification. Now, let’s delve into another innovative option: pyrolysis.

Pyrolysis: Breaking Down Waste in an Oxygen-Starved Environment

Pyrolysis offers a distinct approach to WtE. This thermochemical process decomposes waste materials in an oxygen-deprived environment using high temperatures. Imagine a sealed container heated to a significant degree (around 400°C to 700°C) – that’s the basic setup for pyrolysis. In the absence of oxygen, waste materials break down into various products, unlike the combustion process seen in incineration.

Understanding the Key Differences: A Clear Comparison Chart

While both plasma gasification and pyrolysis are WtE technologies, they operate on fundamentally different principles. Let’s break down their key differences in a clear comparison chart:

| Feature | Mass Burn Incineration | Plasma Gasification | Pyrolysis (including Microwave Pyrolysis) | Hydrothermal Carbonization (HTC) |

|---|---|---|---|---|

| Temperature | High (around 800°C to 1,200°C) | Extremely high (around 12,000°C) | Moderate (around 400°C to 700°C) | High pressure & hot water (around 180°C to 250°C) |

| Process Environment | Oxygen-rich | Oxygen-rich | Oxygen-deprived (may vary with type) | Water-based |

| Waste Types Processed | Primarily municipal solid waste (MSW) | Wide variety (including MSW & hazardous waste) | Primarily organic waste (e.g., food scraps, wood) | Organic waste streams (e.g., sewage sludge) |

| Outputs | Electricity, heat, bottom ash | Syngas (usable fuel), slag, vitrified ash | Bio-oil, char, combustible gases (may vary) | Hydrochar (coal-like fuel), process water |

| Advantages | Proven technology, reliable energy production, significant waste volume reduction | Handles diverse waste streams, potentially lower emissions, syngas for various applications | May require less pretreatment, some liquid fuels produced, potentially cleaner outputs | Suitable for wet waste, produces valuable fuel source, can be integrated with existing power plants |

| Disadvantages | Potential air pollution concerns, requires robust emission control systems | High initial investment costs, complex technology under development | Lower energy output compared to incineration, may require additional processing of outputs | High operational costs, limited waste types processed |

Choosing the Right Tool for the Job

Plasma gasification and pyrolysis cater to different waste management needs. Plasma gasification, with its high-temperature environment, can handle a broader range of waste, including hazardous materials. However, the significant upfront costs and ongoing development needs are considerations. Pyrolysis, on the other hand, might be a suitable option for organic waste streams, potentially producing valuable liquid bio-oil fuels. However, it generally requires additional processing steps and offers a lower energy output compared to incineration.

The choice between these technologies depends on factors like the type of waste, desired outputs, and economic considerations. Both plasma gasification and pyrolysis offer exciting possibilities for the future of WtE, and ongoing research is crucial to further optimize their efficiency and environmental impact.

As we move forward, a multi-pronged approach is vital. While WtE technologies offer promising solutions, waste reduction remains a critical goal. By embracing a combination of strategies – waste reduction, recycling, and WtE – we can create a cleaner and more sustainable future for our planet.

Conclusion

Waste-to-energy (WtE) technologies offer a glimmer of hope in tackling the ever-growing global waste crisis. By transforming trash into a valuable resource – clean energy – WtE presents a compelling solution for waste management and a path towards a more sustainable future.

As we’ve explored, various WtE technologies exist, each with its advantages and disadvantages. Mass burn incineration offers a proven method for waste volume reduction and energy generation, while plasma gasification boasts the potential to handle a wider range of waste materials. Pyrolysis and hydrothermal carbonization present additional options for converting organic waste into valuable fuels.

The future of WtE is bright, with continuous advancements in technology promising even greater efficiency and environmental benefits. However, realizing this potential requires a multi-pronged approach. Government policies that incentivize WtE adoption and ongoing research & development are crucial. Additionally, public education plays a vital role in fostering awareness and acceptance of these technologies.

Ultimately, the success of WtE hinges on a collaborative effort between governments, industries, and individuals. By embracing innovative solutions like WtE alongside waste reduction practices, we can create a cleaner, more sustainable world for generations to come.

Let’s keep the conversation going! Share your thoughts on WtE technologies in the comments below. What are your concerns, and how can we move forward responsibly? Explore more similar content like this: