Introduction: The Rise of Polyfunctional Robots

What Are Polyfunctional Robots?

Polyfunctional robots are advanced robotic systems designed to perform multiple tasks across various domains, making them more flexible and adaptable than traditional single-function robots. Unlike conventional automation, which relies on task-specific robots, polyfunctional robots integrate modular components, AI-driven adaptability, and reconfigurable hardware to execute diverse functions within a single framework.

These robots can dynamically switch between tasks such as assembly, inspection, packaging, material handling, and even medical assistance, reducing the need for multiple specialized machines in industrial, healthcare, and service environments.

The Evolution from Single-Task to Multi-Functional Robotics

The transition from single-task automation to polyfunctional robots has been driven by several key advancements:

- Artificial Intelligence (AI) and Machine Learning – Modern robots leverage AI to interpret real-time data, enabling them to learn new tasks and optimize performance dynamically.

- Modular Robotics – The rise of interchangeable robotic components allows for on-the-fly adaptation to new tasks without requiring a complete redesign of the system.

- Advanced Sensors and IoT Integration – Polyfunctional robots utilize LiDAR, computer vision, haptic feedback, and IoT connectivity to interact seamlessly with changing environments.

- Cloud and Edge Computing – By processing data in real-time through edge AI or cloud-based networks, these robots can update their functionality based on remote software improvements.

This evolution has led to more cost-efficient, space-saving, and high-performing automation solutions that can cater to multiple industries.

The Importance of Flexibility and Modularity in Modern Automation

In industries ranging from manufacturing and logistics to healthcare and smart cities, flexibility is a critical requirement. Traditional robots often require extensive reprogramming and physical modifications to accommodate new tasks, resulting in downtime and high costs.

Polyfunctional robots address these challenges through:

- Self-Optimizing Systems – AI-powered robots analyze workflow patterns and adjust their processes accordingly.

- Interchangeable Tooling and End Effectors – Advanced robotic arms can swap out tools (e.g., grippers, welders, or 3D printing heads) depending on the task at hand.

- Adaptive Motion Planning – Using real-time data, these robots navigate dynamic environments, making them ideal for warehouse automation, autonomous delivery, and emergency response applications.

As multi-functional robotics continue to advance, businesses will experience increased efficiency, reduced operational costs, and enhanced scalability, making polyfunctional robots a cornerstone of next-generation automation.

How Polyfunctional Robots Work

Modular Design and Interchangeable Tools

One of the defining features of polyfunctional robots is their modular architecture, which allows them to adapt to different tasks by swapping out components. Modular robotics consists of reconfigurable robotic units, where different modules can be attached or detached based on task requirements.

Key aspects of modular robotics in polyfunctional robots include:

- Interchangeable End Effectors – Robotic arms can swap tools such as grippers, welding torches, sensors, and 3D printing heads, making them suitable for manufacturing, healthcare, and service industries.

- Self-Reconfigurable Structures – Advanced swarm robots or modular units can physically change shape to navigate complex environments, ideal for search-and-rescue missions or adaptive manufacturing.

- Plug-and-Play Hardware – Components like sensors, AI processors, and motion controllers can be added or removed, ensuring robots remain upgradable as technology advances.

This modularity significantly enhances efficiency, flexibility, and cost-effectiveness, allowing businesses to deploy a single robotic system for multiple use cases rather than investing in task-specific robots.

AI-Powered Adaptability and Machine Learning Integration

Artificial Intelligence (AI) plays a crucial role in the adaptability of polyfunctional robots. Unlike traditional robots that require manual programming for each task, these robots leverage machine learning algorithms to:

- Analyze and learn from real-world data – Robots can identify patterns, optimize workflows, and refine movement precision over time.

- Autonomously adapt to new tasks – AI-driven systems can switch between object detection, navigation, and manipulation without human intervention.

- Enhance collaborative robotics (cobots) – AI allows robots to work alongside humans safely, adjusting their actions based on real-time human interaction.

Notable AI technologies in multi-functional robotics include:

- Deep Learning for Image Recognition – Helps robots detect objects, understand environments, and perform quality control in manufacturing.

- Reinforcement Learning for Autonomous Decision-Making – Enables robots to improve their performance through trial and error, useful in autonomous navigation and adaptive assembly lines.

- Natural Language Processing (NLP) – Allows robots to understand and respond to voice commands, making them more user-friendly in service applications.

By integrating AI-driven adaptability, polyfunctional robots can operate more independently, reducing reliance on human oversight and making automation more intelligent and efficient.

Cloud-Based Control and Real-Time Data Processing

Cloud computing and edge AI have revolutionized robotic automation, allowing polyfunctional robots to process and share data in real time. Instead of relying on local processing power, these robots utilize:

- Cloud Robotics – Offloads complex computations to cloud-based AI systems, reducing hardware costs and increasing processing speed.

- Edge Computing – Processes critical data locally on the robot itself, enabling real-time decision-making with minimal latency.

- 5G and IoT Connectivity – Allows seamless communication between multiple robotic systems, optimizing their coordination in industrial settings.

Benefits of Cloud-Based Control in Robotics:

- Remote Operation & Monitoring – Businesses can oversee robot performance from anywhere in the world.

- Instant Software Updates – Robots can be remotely updated with new capabilities without requiring downtime.

- Data-Driven Optimization – AI continuously analyzes performance metrics, helping robots improve efficiency through predictive analytics.

By integrating modular robotics, AI-powered adaptability, and cloud-based control, polyfunctional robots are shaping the future of versatile automation. These advancements eliminate the limitations of traditional single-task robots, paving the way for multi-purpose robotic systems that can seamlessly transition between tasks across various industries.

Industries That Benefit the Most from Polyfunctional Robots

Polyfunctional robots are revolutionizing industries by providing flexibility, automation efficiency, and AI-driven adaptability. Their ability to switch between tasks, self-optimize through AI, and integrate seamlessly with cloud-based control systems makes them an essential asset in various sectors.

Manufacturing & Assembly: AI-Driven Production Lines

Manufacturing has long been a stronghold for automation, but polyfunctional robots take efficiency to the next level. Unlike traditional industrial robots, which perform a single repetitive task, AI-driven multi-functional robots can:

- Adapt to different assembly processes by changing tools and configurations.

- Reduce downtime by detecting and correcting errors in real-time.

- Improve quality control using advanced vision systems to spot defects in production lines.

Example: Tesla and BMW are integrating AI-powered cobots that work alongside humans in automated assembly lines, reducing operational costs and improving production speed.

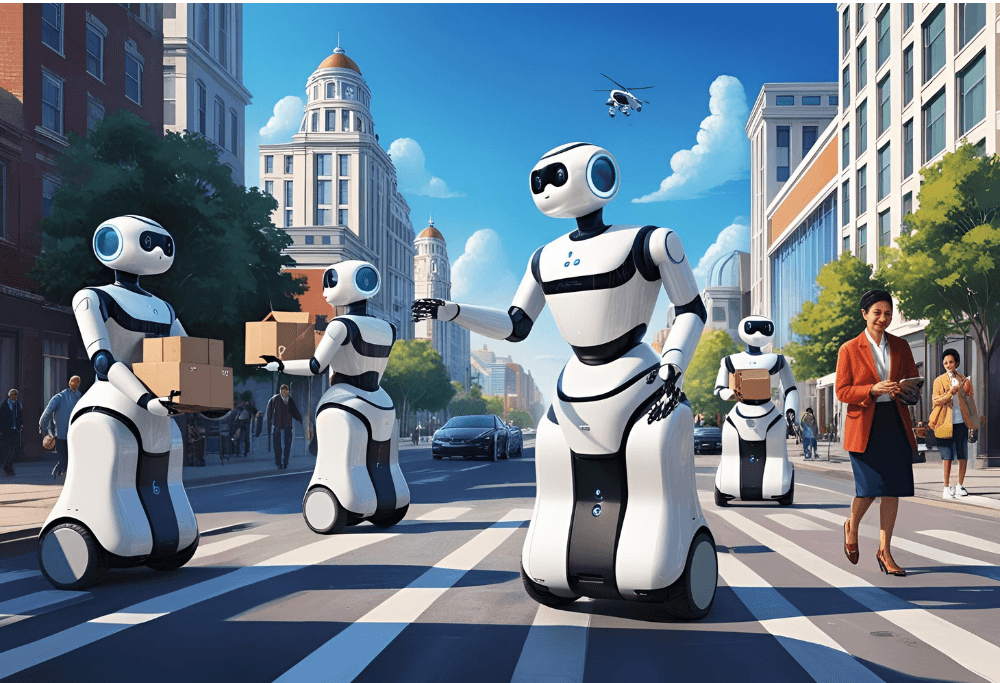

Logistics & Warehousing: Automated Order Fulfillment & Packaging

E-commerce giants like Amazon and Alibaba have pioneered automation efficiency in logistics by deploying robotic fleets that optimize sorting, order picking, and packaging. Polyfunctional robots improve logistics by:

- Enhancing real-time inventory tracking using RFID and computer vision.

- Reducing labor costs with automated material handling systems.

- Speeding up warehouse workflows by dynamically switching between tasks.

Example: Ocado’s automated fulfillment centers use multi-functional robots for rapid order processing, increasing efficiency by over 400%.

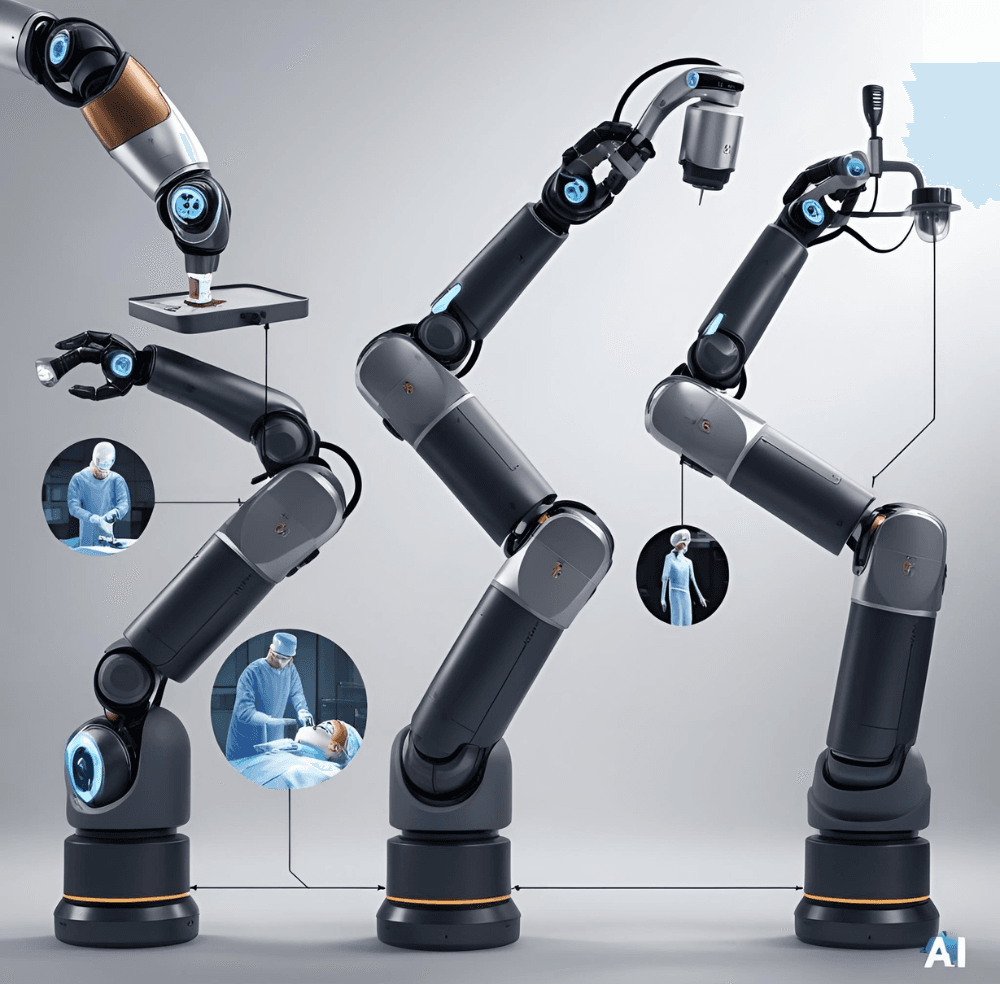

Healthcare & Medical Assistance: Robotics in Surgery & Patient Care

The healthcare sector is rapidly adopting polyfunctional robots for various medical applications, including:

- Surgical Robotics – Systems like da Vinci Surgical Robot enhance precision and reduce human error in minimally invasive procedures.

- Elderly Care & Rehabilitation – AI-driven assistive robots help with physical therapy, patient lifting, and medication reminders.

- Sanitization & Disinfection – Hospitals use UV disinfection robots to combat infections like COVID-19.

Example: Moxi, an AI-powered hospital robot, assists nurses with logistics, medication delivery, and patient monitoring.

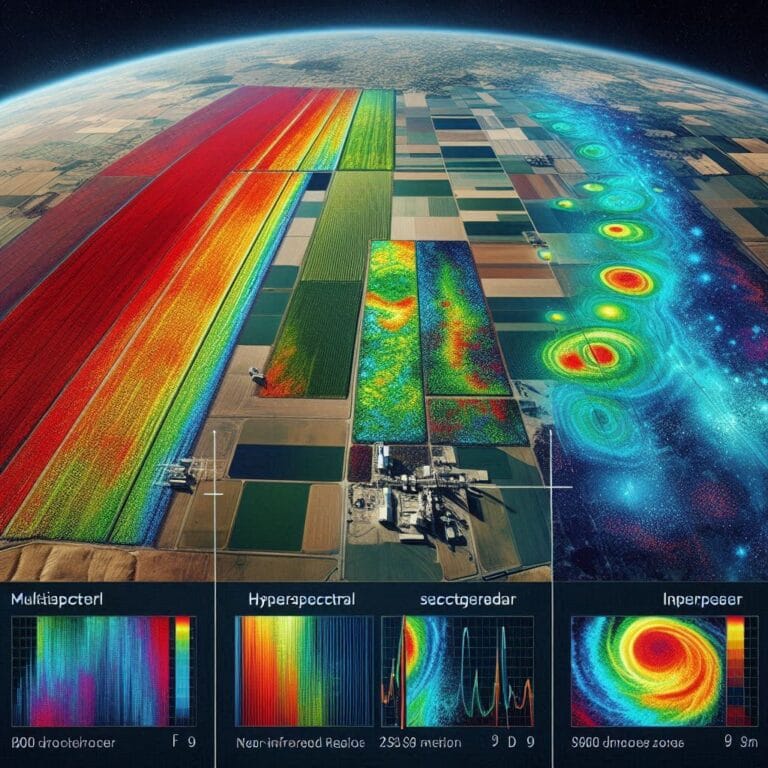

Agriculture: Precision Farming & Sensor-Driven Crop Monitoring

The agricultural industry benefits from polyfunctional robotics through precision farming, which optimizes resources and boosts yield by:

- Deploying AI-powered drones for crop health monitoring.

- Using sensor-driven robotic arms for harvesting, planting, and irrigation.

- Automating livestock care with autonomous feeding and monitoring systems.

Example: John Deere’s AI-driven See & Spray technology uses machine learning to detect and eliminate weeds, reducing pesticide use by 90%.

Retail & Customer Service: AI-Powered Assistants

Retail businesses are leveraging polyfunctional robots to streamline:

- Automated checkout systems in grocery stores.

- Inventory tracking and stock replenishment using AI-powered robots.

- Customer engagement through humanoid robotic assistants.

Example: SoftBank’s Pepper robot provides interactive customer service, while Walmart’s inventory-scanning robots improve supply chain efficiency.

Emergency Response & Security: Search-and-Rescue & Surveillance

In high-risk environments, polyfunctional robots play a crucial role in:

- Disaster response – Robots with thermal imaging, AI navigation, and drone capabilities assist in earthquake and fire rescue operations.

- Military & Law Enforcement – Autonomous surveillance drones and robotic bomb diffusers enhance security and reduce risks.

- Hazardous Material Handling – Robots in nuclear plants and chemical facilities perform dangerous tasks.

Example: The Boston Dynamics Spot robot is used for bomb detection, industrial inspections, and disaster response.

Key Technologies Enabling Polyfunctional Robotics

Advanced Computer Vision & AI for Decision-Making

Machine learning and computer vision enable robots to:

- Recognize and interact with objects in real time.

- Improve navigation through obstacle detection.

- Enhance predictive maintenance for industrial robots.

Example: Tesla’s AI-powered robotic arms dynamically adjust vehicle assembly lines based on sensor inputs.

Sensor Fusion: LiDAR, Ultrasonic Sensors & Thermal Imaging

Multi-sensor integration allows polyfunctional robots to operate autonomously in diverse environments. Key sensors include:

- LiDAR – 3D mapping for autonomous movement.

- Ultrasonic Sensors – Distance measurement for object avoidance.

- Thermal Imaging – Identifying heat signatures in security and medical applications.

Example: Waymo’s autonomous delivery robots use LiDAR and ultrasonic sensors for safe navigation.

Fleet Management Systems for Coordinated Robot Operations

When multiple polyfunctional robots operate together, fleet management software ensures:

- Optimal task allocation to prevent bottlenecks.

- Efficient energy distribution for long battery life.

- Seamless data sharing between robotic units.

Example: Amazon’s Kiva robots use AI-powered fleet management to process over 1 million orders per day in fulfillment centers.

By leveraging automation efficiency, AI-powered adaptability, and sensor-driven precision, polyfunctional robots are set to redefine industries from manufacturing to healthcare, logistics, and emergency response. As robotics technology continues to advance, the integration of machine learning, modular design, and real-time cloud processing will make multi-functional robots indispensable in the coming years.

Business Advantages of Polyfunctional Robots

As automation technology advances, polyfunctional robots are emerging as a cost-effective and scalable solution for businesses across industries. These multi-functional robots enhance efficiency, reduce costs, and improve workforce productivity by integrating AI, machine learning, and modular robotics.

Cost Efficiency: Higher ROI Through Multi-Tasking Capabilities

One of the biggest advantages of polyfunctional robots is their ability to perform multiple tasks, eliminating the need for separate, single-purpose robots. This results in:

- Lower capital investment – Companies invest in a single robotic system instead of multiple specialized machines.

- Reduced downtime – AI-powered adaptability allows robots to switch tasks seamlessly, improving operational continuity.

- Optimized resource allocation – Businesses can allocate resources more efficiently, reducing waste.

Example: Automakers like BMW and Tesla have deployed multi-functional robotic arms that handle assembly, welding, and quality control, cutting production costs significantly.

Scalability & Flexibility: Robots Adapting to Evolving Business Needs

Modern businesses demand scalable and adaptable solutions, and polyfunctional robots fit this requirement perfectly. Their ability to:

- Reconfigure for different workflows with modular components and AI-driven adaptability.

- Expand effortlessly – Businesses can scale robotic fleets with cloud-based coordination.

- Improve production efficiency by learning and optimizing tasks over time.

Example: Amazon’s warehouse robots use real-time data processing to optimize order fulfillment dynamically, scaling with seasonal demand spikes.

Workforce Augmentation: Enhancing Human Productivity, Not Replacing Jobs

Unlike the fear of automation replacing jobs, polyfunctional robots are designed to augment human workers, making workplaces more efficient. Benefits include:

- Reducing repetitive strain – Robots handle physically demanding and repetitive tasks, allowing employees to focus on higher-value activities.

- Enhancing safety – AI-driven robots perform hazardous tasks, reducing workplace accidents.

- Enabling human-robot collaboration – Cobots (collaborative robots) work alongside human employees, increasing overall efficiency.

Example: Miso Robotics’ Flippy assists in fast food kitchens, handling repetitive frying and flipping tasks while workers focus on customer service.

Data-Driven Optimization: Real-Time Analytics for Better Decision-Making

With AI-powered data analytics, polyfunctional robots provide businesses with real-time insights that optimize operations:

- Predictive maintenance – Sensors track robot performance and anticipate breakdowns before they occur.

- Operational analytics – AI algorithms analyze workflow efficiency and suggest improvements.

- Supply chain optimization – Logistics companies use real-time tracking to adjust inventory and shipping strategies dynamically.

Example: UPS and FedEx integrate AI-driven robotics in logistics hubs, reducing delays and optimizing routes based on real-time data.

Challenges and Future Trends in Polyfunctional Robotics

Technical Challenges: AI Training, Battery Efficiency & Software Standardization

Despite rapid advancements, polyfunctional robots face technical hurdles, such as:

- Complex AI training – Teaching robots to adapt to different tasks requires extensive machine learning data.

- Battery limitations – Current battery technologies restrict uptime, necessitating improvements in energy storage.

- Software integration – Different industries use varied software ecosystems, requiring standardized interoperability.

Example: Boston Dynamics’ Spot robot struggles with battery constraints, limiting its operational hours in the field.

Regulatory & Ethical Considerations: Addressing Workforce Displacement Concerns

Governments and industries are debating ethical concerns around automation’s impact on employment:

- Workforce transition programs – Companies must invest in reskilling employees for higher-value roles.

- Regulatory frameworks – Governments are introducing robotics laws to ensure fair labor practices.

- Privacy concerns – AI-powered robots collect vast amounts of data, raising security and privacy issues.

Example: The European Union’s AI Act is setting guidelines for ethical AI and robotics deployment in industries.

Future Outlook: Expansion of Fleet-Managed Robotics in Key Industries

The future of polyfunctional robots lies in fleet-managed AI-driven automation:

- E-commerce & logistics – Companies like Amazon and Alibaba are increasing reliance on autonomous warehouse fleets.

- Healthcare & medical technology – AI-powered surgical assistants and rehabilitation robots are becoming mainstream.

- Smart factories & Industry 4.0 – AI-powered industrial robots will dominate next-generation factories.

Example: Elon Musk’s Tesla Bot aims to revolutionize industrial automation, performing multiple roles in manufacturing and logistics.

FAQ

What are polyfunctional robots, and how do they differ from traditional robots?

Polyfunctional robots are advanced machines designed to perform multiple tasks instead of being limited to a single function. Unlike traditional industrial robots that specialize in one job (like welding or painting), polyfunctional robots can adapt and switch roles depending on the need.

What technologies make polyfunctional robots possible?

These robots rely on AI, machine learning, modular hardware, adaptive sensors, and advanced actuators. Their ability to reprogram, self-learn, and integrate with other systems allows them to handle diverse tasks in dynamic environments.

Which industries are adopting polyfunctional robots the fastest?

Manufacturing, logistics, healthcare, agriculture, and defense are leading the way. For example, a single robot in a warehouse might shift between sorting, packing, and quality-checking—tasks that previously required separate machines.

How can polyfunctional robots benefit businesses and workers?

They increase efficiency, reduce equipment costs, and minimize downtime. For workers, polyfunctional robots can take over repetitive or dangerous tasks, allowing humans to focus on decision-making, creativity, and supervision.

What challenges limit the widespread adoption of polyfunctional robots?

High costs, complex programming, energy demands, and cybersecurity risks remain obstacles. Businesses must balance the investment against the long-term productivity and flexibility these robots provide.

What role will polyfunctional robots play in the future of automation?

They are expected to become the backbone of smart factories, adaptive supply chains, and personalized healthcare. As AI evolves, polyfunctional robots may act as universal assistants—capable of shifting instantly from industrial tasks to home services.

Conclusion: The Future of Polyfunctional Robots in Automation

The rise of polyfunctional robots is reshaping industries by improving automation efficiency, workforce augmentation, and data-driven decision-making. Their ability to adapt to diverse tasks and seamlessly integrate with AI-driven systems makes them a valuable investment for businesses.

Key Takeaways:

- Cost savings & scalability – Businesses can achieve higher ROI with multi-functional robotic systems.

- Workforce augmentation – Rather than replacing jobs, robots enhance human productivity.

- Future expansion – Robotics will play a crucial role in logistics, manufacturing, healthcare, and beyond.

As AI and automation continue to evolve, polyfunctional robots will define the future of robotics, making industries more agile, productive, and data-driven.

Further Reading on Robotics Innovations

Curious about the future of robotics? Explore these in-depth articles:

🔹 Proto Alpha Robot: The Future of AI-Powered Robotics – Learn how advanced AI, neural networks, and synthetic muscles are shaping next-gen humanoid robots.

🔹 Miniature Robots – Discover how small-scale robotics are making big impacts in medicine and industry.

🔹 Robotics in Agriculture – Learn how AI-powered machines are revolutionizing modern farming.

🔹 Revolutionizing Robotics: Artificial Compound Lenses Evolution – Explore how nature-inspired vision systems are advancing robotic perception.

🔹 Swarm Robotics for Environmental Monitoring – See how coordinated robot collectives are being used for ecological conservation.