Introduction: The Growing Problem of Noise Pollution

In the increasingly urbanized world, noise pollution has become a ubiquitous issue. Whether it’s the constant hum of traffic, the roar of airplanes, or the clatter of construction, unwanted noise is an inescapable part of modern life. According to the World Health Organization (WHO), noise pollution is not just an inconvenience—it is a significant environmental hazard that can lead to health problems such as stress, hearing loss, and even cardiovascular diseases.

Traditional noise-canceling technologies, such as active noise-canceling (ANC) headphones, use electronic systems to create sound waves that counteract incoming noise. While effective, these technologies have limitations. They often require power, are limited in the range of frequencies they can cancel, and are not scalable for larger applications such as urban environments or industrial settings.

Enter acoustic metamaterials—a groundbreaking class of engineered materials that have the potential to revolutionize noise cancellation. Unlike traditional noise-canceling technologies, acoustic metamaterials achieve sound attenuation passively, without the need for electronics or power. These materials could pave the way for quieter cities, more comfortable vehicles, and better sound environments in various industries.

This blog will delve into the world of acoustic metamaterials, exploring what they are, how they work, and their advantages over traditional noise-canceling technologies. Discover how acoustic metamaterials can revolutionize noise reduction and transform sound control for everyday life.

Understanding Acoustic Metamaterials: What Are Metamaterials?

Metamaterials are artificially engineered materials designed to have properties that do not occur naturally. These materials derive their unique characteristics not from their composition but from their structure—specifically, the arrangement and geometry of their internal components. Metamaterials can manipulate electromagnetic waves, sound waves, or even seismic waves in ways that natural materials cannot.

How Do Acoustic Metamaterials Differ from Traditional Materials?

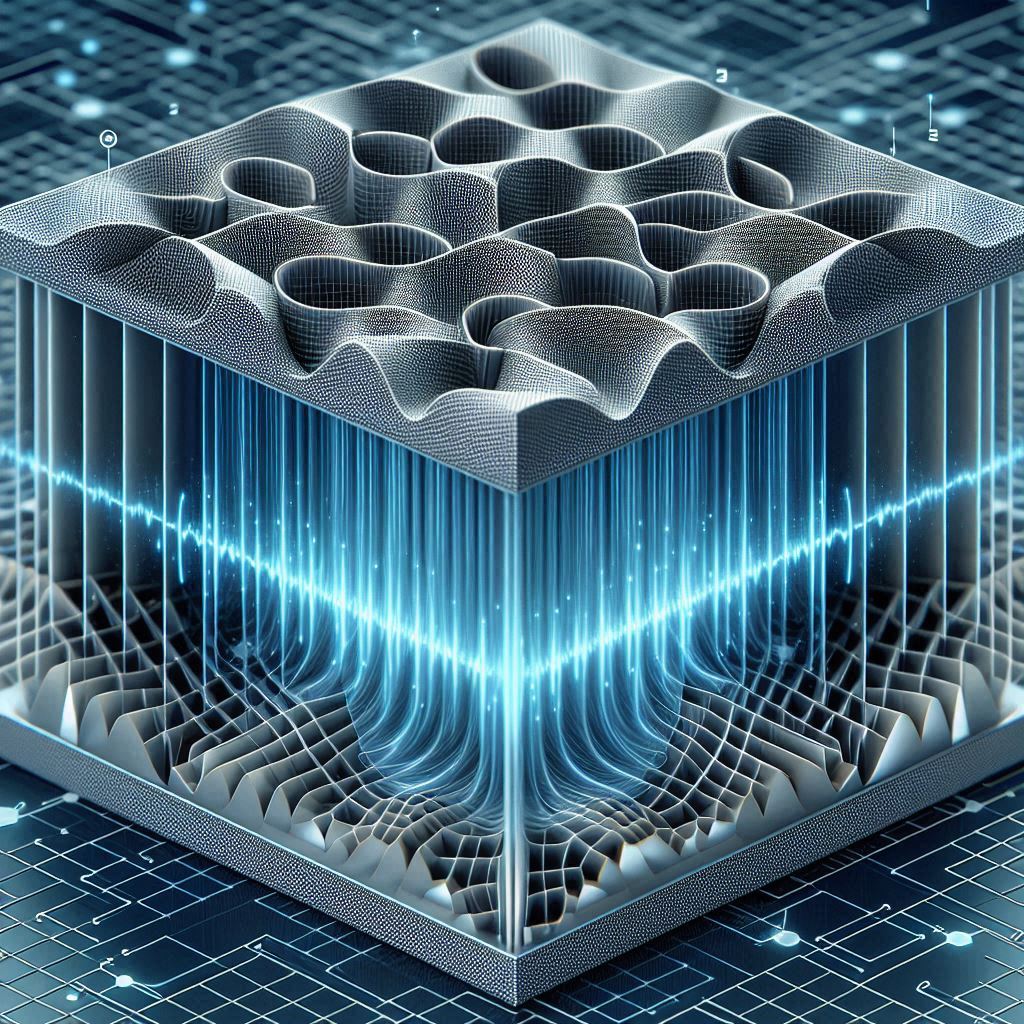

Acoustic metamaterials are a subclass of metamaterials that specifically interact with sound waves. Unlike traditional soundproofing materials like foam or fiberglass, which primarily absorb sound energy, acoustic metamaterials can control, redirect, or block sound waves through their structure. This capability arises from their ability to create “bandgaps”—frequency ranges where sound waves cannot propagate through the material.

Structure and Design of Acoustic Metamaterials

The magic of acoustic metamaterials lies in their intricate design. These materials are often composed of repeating units called “unit cells” that are arranged in a periodic pattern. Each unit cell is carefully engineered to interact with sound waves in specific ways. For example, some designs use resonators—tiny structures within the unit cells that vibrate at specific frequencies—to trap and dissipate sound energy.

The Science Behind Sound Manipulation

Acoustic metamaterials manipulate sound waves through phenomena such as negative refraction and the creation of bandgaps. Negative refraction occurs when sound waves bend in the opposite direction compared to how they would in natural materials. This property can be used to create “acoustic cloaks” that guide sound waves around an object, effectively making it invisible to sound.

Bandgaps, on the other hand, are frequency ranges where sound waves cannot pass through the material. By tuning the size and shape of the unit cells, engineers can design acoustic metamaterials to block specific frequencies of sound, making them highly effective for targeted noise cancellation.

Comparison to Traditional Noise-Canceling Technologies

Traditional noise-canceling technologies rely on active systems that detect incoming noise and generate sound waves with the same amplitude but opposite phase to cancel it out. While effective, these systems are complex, require power, and are limited in the range of frequencies they can cancel. Acoustic metamaterials, by contrast, passively achieve noise cancellation without power or complex electronics. This makes them more versatile, scalable, and potentially more efficient in various applications.

The Science Behind acoustic metamaterials for noise reduction

Sound Wave Interaction with Acoustic Metamaterials

When sound waves encounter acoustic metamaterials, several mechanisms can come into play, depending on the design of the material. One common mechanism is the creation of destructive interference, where the structure of the material causes incoming sound waves to interfere with each other in a way that cancels them out.

Another mechanism is the use of resonators within the metamaterial. These resonators can be designed to oscillate at specific frequencies, trapping sound energy and preventing it from propagating further. This is particularly useful for targeting specific noise sources, such as low-frequency rumble from machinery or high-pitched whine from electronics.

Case Studies and Design Examples

One notable example of acoustic metamaterial design is the labyrinthine structure, which uses a complex network of pathways to trap and dissipate sound waves. These structures can be incredibly effective at blocking sound, even in thin or lightweight materials. Researchers at Boston University, for example, have developed a 3D-printed metamaterial that can block 94% of incoming sound while allowing air to pass through—a breakthrough with potential applications in ventilation systems and noise barriers.

Another example is the use of membrane-type acoustic metamaterials (MAMs), which consist of a thin membrane stretched over a frame with small masses attached. These MAMs can be tuned to block specific frequencies, making them ideal for applications like soundproofing in buildings or noise reduction in vehicles.

Advantages Over Traditional Methods

No Need for Electronics or Power Supply

One of the most significant advantages of acoustic metamaterials is that they do not require any external power source or electronic components to function. This makes them ideal for applications where power consumption is a concern, such as in remote locations or in devices where battery life is critical.

Potential for Higher Efficiency in Specific Applications

Acoustic metamaterials can be designed to target specific frequencies or types of noise, making them more efficient than traditional materials in certain applications. For example, a metamaterial designed to block the low-frequency hum of an air conditioning unit could be far more effective than conventional soundproofing materials, which tend to be less effective at low frequencies.

Longevity and Maintenance Benefits

Since acoustic metamaterials do not rely on electronic components or active systems, they are generally more durable and require less maintenance than traditional noise-canceling technologies. This can lead to lower long-term costs and increased reliability, especially in industrial or outdoor applications where maintenance can be challenging.

Current and Emerging Applications

Construction Industry: Building Quieter Urban Environments

Noise pollution is a major concern in urban environments, where dense populations and heavy traffic create constant background noise. Acoustic metamaterials have the potential to revolutionize urban soundscapes by providing more effective noise barriers and soundproofing materials. For example, walls or windows incorporating acoustic metamaterials could significantly reduce the amount of traffic noise that enters buildings, creating quieter and more comfortable living spaces.

Soundproofing Materials for Buildings

Traditional soundproofing materials like fiberglass and foam have limitations, particularly when it comes to low-frequency noise. Acoustic metamaterials offer a promising alternative, with the potential to block a wider range of frequencies more effectively. This could be particularly beneficial in settings like apartment buildings or offices, where noise from neighboring units can be a major issue.

Transportation Sector:

Noise Reduction in Automotive and Aerospace Industries

The transportation sector is another area where acoustic metamaterials could have a significant impact. In automobiles, for example, acoustic metamaterials could be used to reduce cabin noise, improving the comfort of passengers. In airplanes, these materials could be used to create quieter cabins without adding significant weight, which is a critical consideration in aviation.

Researchers are already exploring the use of acoustic metamaterials in these industries. For example, a team at the University of Michigan has developed a lightweight acoustic metamaterial that can be used in car panels to reduce road noise. Similarly, aerospace companies are investigating the use of metamaterials to reduce engine noise and improve passenger comfort on long flights.

Audio Engineering

Enhancing Sound Quality in Recording Studios and Concert Halls

In the field of audio engineering, acoustic metamaterials could be used to create more precise control over sound environments. For example, these materials could be used in recording studios to eliminate unwanted reflections and create a more neutral sound space. In concert halls, acoustic metamaterials could be used to enhance the clarity and quality of sound, providing a better experience for both performers and audiences.

Creating More Effective Noise-Canceling Headphones and Speakers

Noise-canceling headphones and speakers are already popular consumer products, but they have limitations, particularly when it comes to blocking low-frequency noise. Acoustic metamaterials could be used to create more effective noise-canceling devices, with the ability to block a wider range of frequencies without the need for complex electronic systems. This could lead to headphones that are not only more effective at canceling noise but also more comfortable to wear and longer lasting.

Healthcare

Reducing Noise Pollution in Medical Settings

Noise pollution is a significant issue in healthcare environments, where constant noise can create stress for both patients and staff. Acoustic metamaterials could be used to create quieter hospital rooms, reducing stress and improving patient outcomes. Additionally, these materials could be used in medical devices to reduce noise, making them more comfortable for patients to use.

Applications in Medical Devices

Beyond noise reduction, acoustic metamaterials could also be used in medical devices themselves. For example, they could be used to create more precise ultrasound equipment, with the ability to focus sound waves more effectively. This could lead to better imaging and more accurate diagnoses.

Challenges and Limitations

Technical Challenges

Current Limitations in Manufacturing and Scalability

While the potential of acoustic metamaterials is enormous, there are still significant challenges to be overcome before they can be widely adopted. One of the biggest challenges is manufacturing. Acoustic metamaterials often require precise and complex structures, which can be difficult and expensive to produce at scale. Advances in 3D printing and other manufacturing technologies are helping to address these challenges, but there is still work to be done.

Need for Further Research and Development

The field of acoustic metamaterials is still relatively young, and much more research is needed to fully understand the potential and limitations of these materials. Researchers are actively exploring new designs and applications, but it will take time to translate these findings into practical, real-world solutions.

Economic and Market Considerations

Another challenge is cost. Acoustic metamaterials are currently more expensive to produce than traditional noise-canceling materials. While this cost is expected to decrease as manufacturing techniques improve and the technology matures, it remains a barrier to widespread adoption.

Market Readiness and Adoption Barriers

Finally, there are market readiness and adoption barriers to consider. Many industries are conservative when it comes to adopting new technologies, particularly when they involve significant upfront costs. Educating the market about the benefits of acoustic metamaterials and demonstrating their long-term value will be key to overcoming these barriers.

The Future of Acoustic Metamaterials

Overview of Ongoing Research and Potential Breakthroughs

Research into acoustic metamaterials is advancing rapidly, with discoveries and breakthroughs being reported regularly. For example, recent studies have explored the use of acoustic metamaterials in underwater applications, such as sonar systems and noise reduction for submarines. Other research is focused on creating tunable metamaterials that can be adjusted to block different frequencies on demand.

Predictions for How the Technology Might Evolve

As the technology matures, we can expect to see acoustic metamaterials becoming more versatile and customizable. Future metamaterials may be able to adapt to different noise environments automatically or be integrated into smart systems that optimize noise control in real time. This could lead to a new generation of noise-canceling technologies that are more effective, efficient, and user-friendly.

Long-Term Implications

Potential to Disrupt Multiple Industries

The potential of acoustic metamaterials to disrupt multiple industries is immense. From construction to transportation to healthcare, these materials could fundamentally change the way we approach noise control and sound management. As the technology becomes more widely adopted, we could see significant improvements in the quality of life for people living in noisy environments, as well as new opportunities for innovation in industries that rely on precise sound control.

Environmental and Societal Impact

Beyond the technical and economic implications, acoustic metamaterials also have the potential to make a significant environmental and societal impact. By reducing noise pollution in urban areas, these materials could contribute to healthier, more livable cities. They could also play a role in reducing the environmental impact of transportation and industry by making it easier to manage and control noise.

Conclusion

Acoustic metamaterials represent a groundbreaking new approach to noise cancellation, potentially revolutionizing industries ranging from construction to transportation to healthcare. Unlike traditional noise-canceling technologies, acoustic metamaterials achieve sound attenuation passively, without the need for electronics or power. This makes them more versatile, scalable, and potentially more efficient in a wide range of applications.

Call to Action

As research and development in this field continue to advance, industry professionals, policymakers, and the public must stay informed about the potential of acoustic metamaterials. By understanding the benefits and challenges of this emerging technology, we can better prepare for a future where noise pollution is no longer an inescapable part of modern life.

Further Reading and Resources

For those interested in exploring this topic further, numerous academic papers, industry reports, and news articles are available that delve deeper into the science and applications of acoustic metamaterials. I encourage you to seek out these resources and stay informed about the latest developments in this exciting field.

Explore More Such Topics: