Introduction- Cotton Gin Invention:

The history of cotton is intricately woven with the story of the cotton gin. This seemingly simple machine, by separating the fluffy fibers from stubborn seeds, sparked a revolution that transformed not just the textile industry, but the course of history.

Often credited to Eli Whitney, the cotton gin’s invention in 1793 became a pivotal point in the Industrial Revolution. But the story goes far beyond one man and one machine. Join us as we delve into the fascinating world of cotton and ginning, exploring its impact on slavery, the rise of “King Cotton,” and the lasting legacy of Eli Whitney’s inventions.

This blog will unpack the cotton gin’s description, its role in the Industrial Revolution, and the complex relationship between the cotton gin and slavery. We’ll separate fact from fiction, untangling the threads of history to reveal the true impact of this ingenious machine, the cotton gin.

How Does the Cotton Gin Work? Separating Cotton Fibers with Saws and Brushes

The cotton gin, short for “engine,” is a machine that revolutionized the processing of cotton. Invented in 1793 by Eli Whitney, it dramatically increased the efficiency of separating cotton fibers from their seeds, making cotton production much more profitable.

Here’s a breakdown of the ginning process using saws and brushes:

Feeding the Gin:

- Raw cotton, with fibers clinging to the seeds (called ginning or seed cotton), is fed into a feeder at the beginning of the machine.

Separation with Saws:

- The feeder directs the cotton to a set of rotating saws. These saws have sharp teeth that grab the cotton fibers and pull them through a grate with narrow openings.

- The openings in the grate are just large enough for the fibers to pass through, but too small for the much larger seeds. This traps the seeds on one side of the grate while the fibers are pulled through to the other side.

Brushing Off and Cleaning:

- Once separated from the seeds, the cotton fibers may still have some trash or immature seeds clinging to them. These are removed by another rotating cylinder equipped with brushes.

- The brushes rapidly spin, beating the cotton and dislodging any remaining debris.

Final Touches:

- The clean cotton fibers are then collected and baled for storage and transport.

- The separated seeds are also collected and can be used for planting new cotton crops or sent for further processing to extract cottonseed oil and cottonseed meal.

Modern Cotton Gins:

While the basic principle of using saws and brushes remains the same, modern cotton gins are much more sophisticated than Whitney’s original invention. They are often powered by electricity and utilize multiple stages of cleaning and separation to ensure high-quality cotton.

This process significantly increased cotton production and processing speed, but it also unfortunately fueled the demand for enslaved labor on cotton plantations in the American South.

History of the Cotton Gin

Early Attempts:

Cotton, with its soft fibers, has captivated humans for millennia. Evidence suggests its use in textiles dates back as far as 5800 BC in the Indus Valley Civilization. However, processing this natural wonder presented a significant challenge: separating the fluffy fibers from the stubborn seeds.

Early efforts at “ginning” (the process of removing seeds) relied on primitive tools like the churka. This hand-operated device, used primarily in India for long-staple cotton, consisted of a small roller ginning a single boll at a time. While effective for long fibers, the churka was woefully inadequate for the short-staple cotton that dominated the American South.

The short-staple cotton variety, native to the Americas, offered several advantages. It thrived in the Southern climate, required less fertile land, and produced higher yields compared to long-staple varieties. However, its short fibers became hopelessly entangled with the seeds when processed with the churka. This entanglement made separating the fibers a labor-intensive and time-consuming task.

Historians estimate that separating seeds from a pound of short-staple cotton by hand could take a skilled worker an entire day. This bottleneck severely limited the potential for large-scale cotton production in the South, despite the growing demand for cotton textiles in Europe and America.

Several attempts were made to improve upon existing ginning technology. In 1772, a man named Krebs patented a modification to the churka, but it still proved ineffective for short-staple cotton. Joseph Eve made further modifications in 1788, but these too were limited in their application.

The South desperately needed a solution, and the stage was set for a young inventor named Eli Whitney to enter the scene and forever change the course of history.

1794: Cotton Gin By Eli Whitney (A Patent and a Piracy Problem)

- 1793 marks a pivotal year in history, not just for the textile industry, but for the trajectory of the United States. It was in this year that a young inventor named Eli Whitney, then just 28 years old, unveiled the cotton gin, a seemingly simple machine destined to spark a revolution.

- Born in 1765 in Westborough, Massachusetts, Whitney’s early life hinted at a bright future. He excelled in academics and displayed a natural aptitude for mechanics. After graduating from Yale in 1792, Whitney initially planned to pursue a career in law. However, fate intervened when he accepted a position as a tutor on a Southern plantation.

- A Southern Education: Here, amidst the sprawling cotton fields, Whitney encountered a stark reality – the limitations of processing short-staple cotton. Unlike the long-staple cotton grown in other regions, the dominant variety in the South presented a significant challenge. Separating the sticky seeds from the short fibers with existing hand tools like the churka was a backbreaking and time-consuming process.

- A Turning Point: This inefficiency piqued Whitney’s curiosity and ignited his innovative spirit. Historical accounts, such as Whitney’s own correspondence documented in the “Yale Eli Whitney Papers,” reveal his fascination with the problem and his determination to find a solution. He meticulously studied cotton fibers’ properties and the challenges short-staple varieties posed.

- Inspiration Strikes: While the exact details surrounding the “Eureka moment” remain mysterious, Whitney is credited with inventing the cotton gin in 1793. Some historians believe his inspiration may have come from observing slaves using a wire brush to separate cottonseed from their meals, a method that sparked the idea for using saws to achieve the same task more efficiently.

- Beyond the Machine: Whitney’s impact extends far beyond the invention itself. He is also credited with pioneering the concept of mass production using interchangeable parts. This innovation, initially developed to streamline cotton gin production, would later have a profound impact on various industries during the Industrial Revolution.

A Flood of Fakes: According to a report by the U.S. Patent Office in 1859, Whitney faced a constant barrage of patent infringements. Planters across the South, eager to capitalize on the cotton boom, readily adopted cruder versions of the gin, often built by local blacksmiths. These “gin stands” functioned similarly to Whitney’s design, but lacked the precision and efficiency of the original.

Legal Woes: Whitney spent a significant portion of his life and resources battling these infringements in court. He launched numerous lawsuits against plantation owners and gin manufacturers, but with limited success. The legal system of the time was slow and expensive, and enforcing patents across vast geographical distances proved challenging.

Financial Frustration: Historical estimates suggest that Whitney earned a mere $50,000 from his patent throughout his lifetime, a meager sum considering the immense impact of his invention. The burden of legal battles and the widespread copying of his design left him financially strained.

A Catalyst for Change: Despite Whitney’s personal struggles, his patent battle ironically contributed to the acceleration of the cotton gin’s spread. As planters across the South built or commissioned their on versions of the gin, its adoption became widespread. This rapid diffusion, even if fueled by patent infringement, ultimately led to the tripling of cotton production in the United States by 1800.

Reference:

The Early 1800s: The Rise and Paradox of “King Cotton”

The dawn of the 19th century witnessed the South’s transformation into a cotton empire, fueled by the transformative power of the cotton gin. With Whitney’s invention dramatically increasing processing efficiency, cotton production skyrocketed. Data compiled by the U.S. Census Bureau reveals a staggering 1,600% increase in cotton production between 1790 and 1820. This surge earned cotton the moniker “King Cotton,” signifying its dominance in the Southern economy.

A Boon for the South: The cotton boom brought about undeniable prosperity for many white Southerners. Land prices soared, and new towns sprung up to support the burgeoning cotton trade. Southern ports like Charleston and New Orleans became bustling hubs of commerce, facilitating the export of cotton to textile mills across the globe.

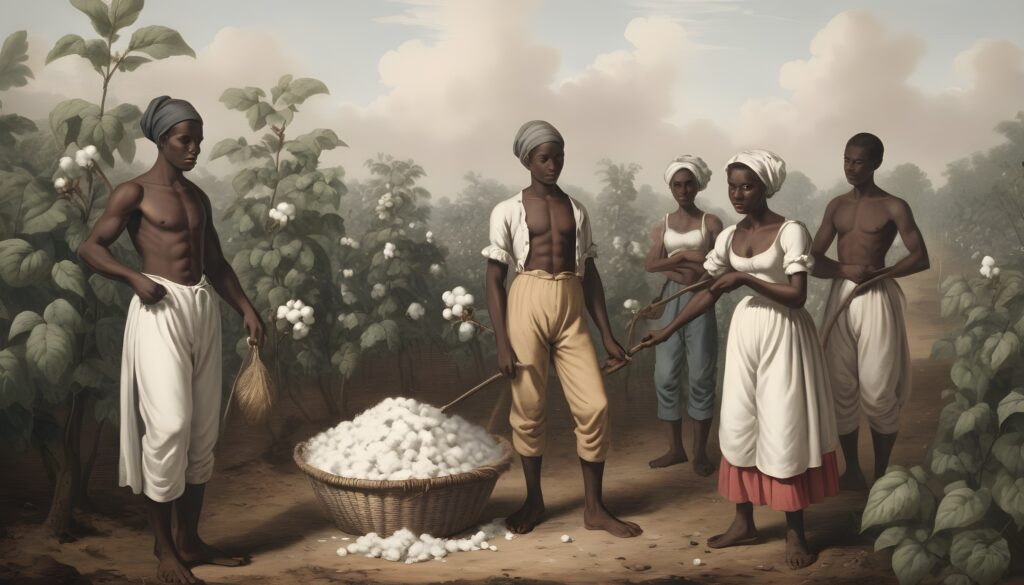

How Did the Cotton Gin Affect Slavery?

A Dark Side to Progress: However, the rise of “King Cotton” came at a horrific cost. The increased demand for cotton cultivation intensified the reliance on slave labor. Historical records, such as the Slave Population of the United States compiled by the U.S. Census Bureau, show a dramatic increase in the slave population across the South, particularly in cotton-producing states. Between 1790 and 1860, the enslaved population in the South quadrupled, driven by the insatiable demand for cheap labor to cultivate and harvest cotton.

Here are some lesser-known facts about the cotton gin and slavery:

- Hope for the gradual end of slavery: After the American Revolution, some believed slavery would decline due to moral reasons and the unprofitability of crops like tobacco. The cotton gin’s invention dashed those hopes.

- Fueling westward expansion: The cotton gin made cotton king, but it also required more land. This spurred Southern migration westward, creating new slave states and increasing demand for enslaved people.

- Internal slave trade boom: The need for more slaves led to a brutal internal slave trade within the US. Millions were forcibly relocated from the upper South to the Deep South to toil on cotton plantations.

- Not a labor-saving device altogether: The gin only sped up seed removal, not cotton picking. This backbreaking work remained dependent on vast amounts of enslaved labor.

- Impact beyond the South: The cotton gin’s influence wasn’t just regional. Northern textile mills boomed due to the increased cotton production, further entrenching the economic system reliant on slave labor.

A Different Perspective: It’s important to acknowledge the ongoing debate surrounding the cotton gin’s role in perpetuating slavery. Some scholars argue that slavery was already a deeply entrenched institution in the South, and the cotton gin merely exacerbated an existing problem. Others, however, contend that the invention’s impact was more profound. The increased profitability of cotton cultivation, they argue, created a powerful economic incentive for the expansion of slavery, ultimately delaying its abolition and shaping the course of American history.

A Legacy of Complexity: The story of the cotton gin in the early 1800s is a complex narrative of economic progress intertwined with human exploitation. “King Cotton” may have brought prosperity to some, but for millions of enslaved people, it represented a deeper entrenchment in a system of forced labor. This duality remains a crucial aspect of the cotton gin’s legacy, prompting reflection on the ethical consequences of technological innovation.

Historical References:

- U.S. Census Bureau (1790-1860). Slave Population of the United States.

- U.S. Census Bureau. (n.d.). Historical Cotton Statistics.

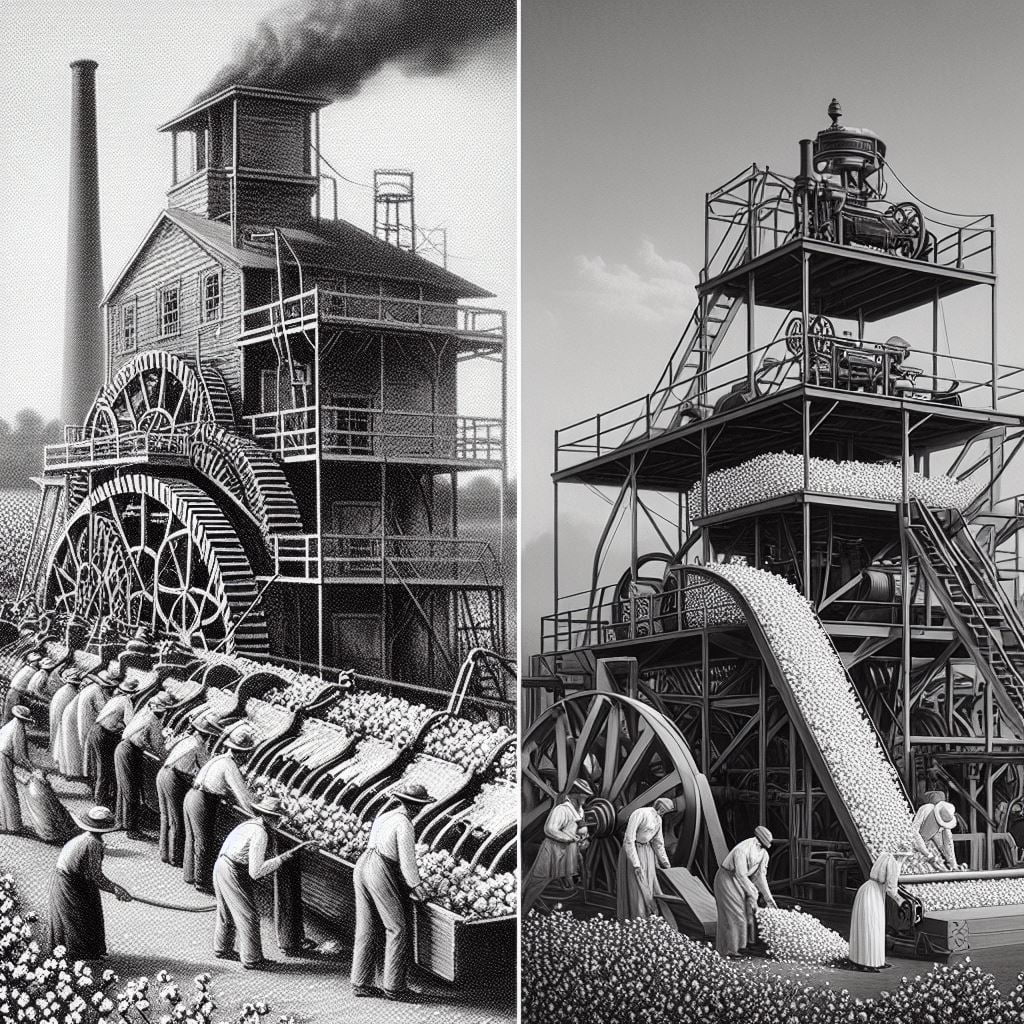

Late 1800s – Early 1900s: Refining the Machine

While Eli Whitney’s cotton gin revolutionized the industry, it wasn’t the final word in cotton processing technology. The late 1800s and early 1900s witnessed a period of continuous improvement and adaptation.

- Roller Gins Take the Stage: One significant innovation was the development of the roller gin. This design, particularly effective for long-staple cotton, utilized a series of rotating rollers to separate fibers from seeds. While less efficient for short-staple cotton, roller gins offered a gentler processing method, minimizing fiber damage, a crucial factor for higher-quality textiles.

- Steam Power Boosts Efficiency: The introduction of steam power in the mid-19th century further transformed cotton ginning. Replacing reliance on water or animal power, steam engines dramatically increased processing speeds and capacity. This shift not only boosted production but also facilitated the rise of larger, centralized ginning facilities.

- The Rise of the Roller Gin Controversy: The emergence of roller gins wasn’t without controversy. Some Southern planters, heavily invested in Whitney’s saw gin design, initially resisted the new technology. However, the advantages of roller gins for specific cotton varieties ultimately led to their widespread adoption, particularly in regions focused on long-staple cotton production.

20th Century: The Cotton Gin Marches On

The 20th century saw the continued evolution of the cotton gin. Here are some key advancements:

- Electric Motors Take Over: By the mid-20th century, electricity replaced steam power as the primary source of energy for cotton gins. This transition offered greater efficiency, control, and flexibility in the ginning process.

- The Rise of the Gin Stand: Smaller, portable gin stands, often powered by gasoline engines, became popular for smaller farms. This innovation allowed for on-site processing, reducing transportation costs and offering greater control over processing schedules.

- Focus on Efficiency and Automation: Throughout the 20th century, the focus remained on increasing efficiency and automation within cotton gins. Technological advancements like pneumatic conveying systems for transporting cotton and automated seed separation processes streamlined operations and reduced labor requirements.

21st Century: Is the Cotton Gin Still Used Today?

Absolutely, the cotton gin remains a crucial part of cotton production even today. While Eli Whitney’s original invention laid the groundwork, modern gins are far more sophisticated and efficient. Here’s how they’ve evolved:

Automation: A Robotic Revolution

Gone are the days of relying on a large workforce to operate cotton gins. Modern gins are heavily automated, employing a network of robotic arms, conveyor belts, and sensor systems. These automated systems take over many of the tasks previously performed by human labor, including:

- Feeding raw cotton: Automated feeders precisely introduce cotton into the ginning process, ensuring consistent flow and optimal processing speeds.

- Gin stand operation: Computer-controlled systems manage the operation of the gin stands, adjusting saw settings and air pressure based on real-time data.

- Bale handling: From compressing the fibers to wrapping and tying the finished bales, modern gins utilize robotic systems for efficient and safe bale handling.

This automation revolution not only reduces labor costs but also increases processing speed. Modern gins can now process significantly larger quantities of cotton in a shorter timeframe compared to their less-automated predecessors.

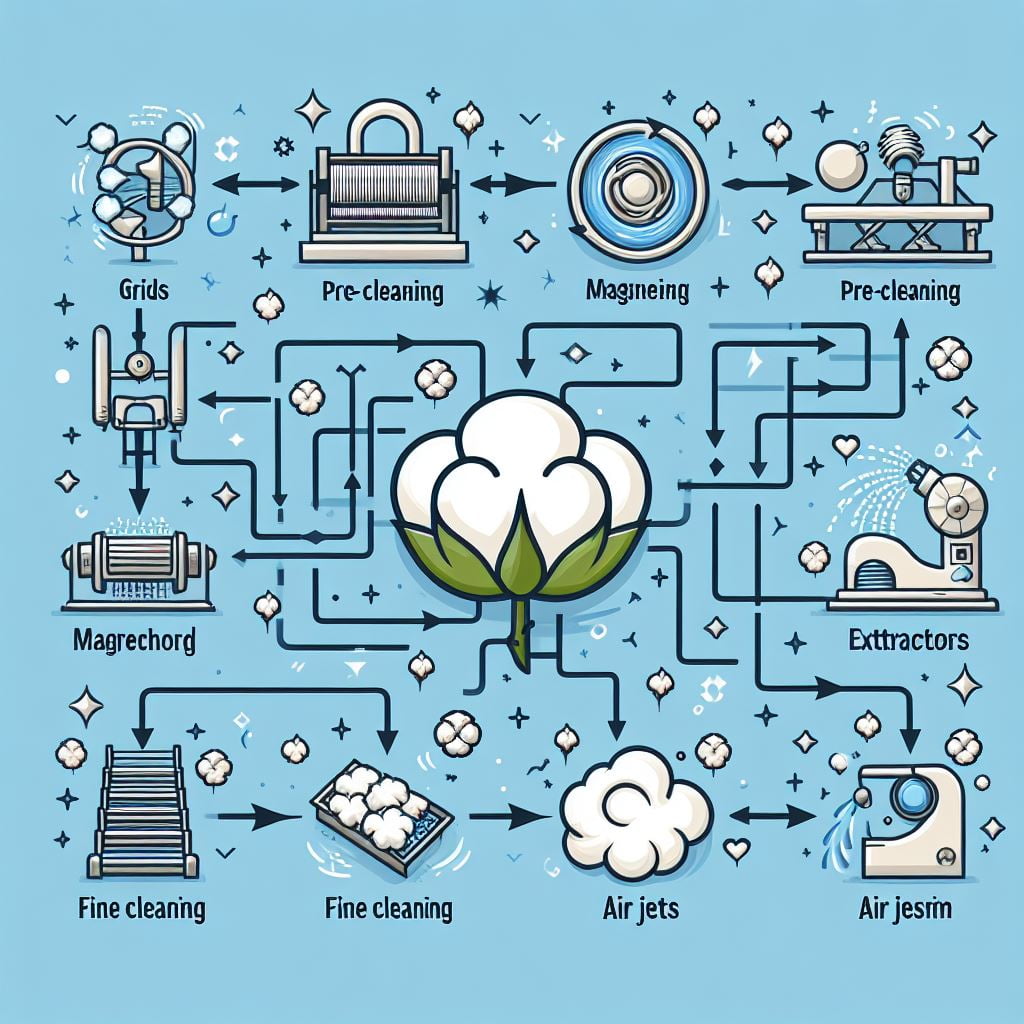

Multi-Stage Cleaning: A Commitment to Pristine Fibers

The cleanliness of raw cotton directly impacts the quality of the final textile product. Modern gins go beyond basic cleaning to ensure the removal of even the tiniest impurities. This multi-stage cleaning process often involves:

- Pre-cleaners: These initial stages utilize grid screens and air currents to remove large debris like leaves, sticks, and stalks.

- Extractors: Specialized machines, like magnetic separators and drum beaters, remove metallic objects and other unwanted materials that could damage processing equipment.

- Fine cleaners: The final cleaning stages, employing advanced technologies like optical sorters and pneumatic chambers, meticulously remove even the tiniest dust particles and vegetable matter that might have escaped earlier stages.

This meticulous cleaning process ensures that only the highest-quality fibers reach the ginning stage, ultimately leading to the production of stronger, smoother, and more desirable textiles.

Air Blast Separation: A Gentle Touch for Delicate Varieties

While the traditional saw ginning method remains highly effective, some modern gins incorporate an additional technique: air blast separation. This method utilizes powerful jets of air to gently separate the fibers from the seeds. This approach offers several advantages:

- Reduced Fiber Damage: Air blasts are particularly beneficial for processing Pima cotton, a delicate and long-staple variety known for its luxurious feel. The gentler separation method minimizes fiber breakage, preserving the quality and value of these premium cotton types.

- Improved Efficiency: Modern air blast systems can be highly efficient, particularly when combined with traditional saw ginning. The air blasts can help to loosen the fibers from the seeds before the saws complete the separation, ultimately speeding up the overall ginning process.

Computerized Control: Precision at Every Step

Modern cotton gins are no longer one-size-fits-all machines. Computerized control systems allow gin operators to precisely adjust the various stages of the ginning process based on real-time data and the specific characteristics of the cotton being processed. These adjustments can include:

- Saw speed control: The speed of the saws can be fine-tuned to optimize fiber separation while minimizing damage.

- Air pressure regulation: The air pressure used in both cleaning and separation stages can be adjusted to ensure optimal efficiency for different cotton varieties.

- Moisture content monitoring: Computerized systems can monitor the moisture content of the cotton and adjust drying processes accordingly, ensuring proper fiber separation and preventing mold growth during storage.

This level of precision control allows for maximized efficiency and minimized waste, ultimately leading to a higher-quality final product.

Environmental Considerations: A Sustainable Future

The modern cotton ginning industry recognizes the importance of environmental responsibility. Manufacturers are increasingly incorporating dust control systems into their gin designs. These systems capture and filter dust particles generated during the ginning process, minimizing air pollution and ensuring a cleaner working environment for employees. Additionally, advancements in energy-efficient components are helping to reduce the overall power consumption of modern gins. This focus on sustainability not only benefits the environment but also helps to ensure the long-term viability of the cotton industry.

These advancements have significantly increased the efficiency and quality of cotton ginning, making the process faster, more precise, and less labor-intensive.

Cotton Ginning Process (The Modern Take)

The cotton gin’s core principle – separating fibers from seeds – may remain constant, but modern ginning is a far cry from Eli Whitney’s original invention. Today’s high-tech gins are marvels of efficiency, transforming raw cotton into bales ready for textile mills. Let’s delve into the fascinating steps of the modern cotton ginning process:

Drying: From Field to Fluffy (But Not Too Fluffy)

Freshly harvested cotton often contains residual moisture from the field. This moisture can hinder the ginning process and even lead to mold growth during storage. To address this, modern gins utilize driers. These dryers can be mechanical or utilize hot air to gently reduce the cotton’s moisture content to a precise level. This ensures efficient processing downstream and creates a shelf-stable product.

Cleaning: Out with the Bad, In with the Good

Imagine a conveyor belt filled with cotton – not just fluffy fibers, but also leaves, sticks, and other debris left over from harvesting. This is where the cleaning stage comes in. Cotton enters a series of machines, including cyclones and impact cleaners, that utilize air currents and vibrations to meticulously remove these unwanted elements. Think of it as a high-tech cotton salad, where the fluff (the good stuff) is separated from the unwanted “dressing.” This meticulous cleaning ensures a higher-quality final product for textile mills.

Ginning: The Heart of the Operation

Now comes the defining moment – the separation of fibers from seeds. Modern gins employ a sophisticated combination of saws, air blasts, and brushes for this task. Here’s a breakdown of the key players:

- Saws: These specially designed saws gently “rip” through the cotton, severing the fibers from the seeds. The design and speed of the saws are carefully calibrated to minimize fiber damage, a crucial factor for high-quality textiles.

- Air Blasts: Powerful blasts of air help to further separate the fibers from the seeds and remove any lingering debris loosened by the saws.

- Brushes: Rotating brushes gently remove any remaining tangled fibers from the seeds, ensuring a clean separation.

It’s important to note that the specific configuration – the number and type of saws, air pressure, and brush settings – may vary depending on the type of gin (roller gin for long-staple cotton, saw gin for short-staple) and the specific cotton variety being processed.

Packaging: From Fluffy to Formidable

Once the separation is complete, the clean cotton fibers are ready for the final step – packaging. These fibers are fed into a baling press, where they are compressed into tightly packed and densely formed bales. Modern bales are significantly larger and denser than those produced by historical gins, maximizing storage and transportation efficiency.

Seed Processing: A Valuable Byproduct

The ginning process doesn’t stop at the fibers. The separated seeds, a valuable byproduct, are collected and put to good use. Some seeds are kept for planting new cotton crops, continuing the cycle. Others are sent for further processing to extract cottonseed oil, a versatile oil used in cooking and various industrial applications. The remaining seed meal, rich in protein, is often used as livestock feed.

The Modern Cotton Gin: A Symphony of Technology

This multi-step process, meticulously controlled by computers and automated systems, ensures efficient and high-quality cotton processing. The modern cotton ginning process is a testament to how far this technology has come since Whitney’s original invention. It’s a fascinating example of how innovation continues to shape agriculture and the textile industry.

Is the Cotton Gin Good or Bad? (A Complex Legacy)

The invention of the cotton gin by Eli Whitney in 1793, stands as a powerful symbol of American ingenuity with a complex and controversial legacy. Its impact transcended the realm of technology, deeply influencing the South’s economy, the global textile industry, and most tragically, the institution of slavery.

The Good:

- Economic Engine for the South: Prior to the gin, processing short-staple cotton, the variety most prevalent in the South, was a laborious and time-consuming process. The gin drastically reduced processing time, making cotton production significantly more profitable. According to historical records, cotton production in the US increased from around 3,000 bales in 1790 to a staggering 1.7 million bales by 1820. This economic boom fueled infrastructure development in the South, with the construction of railroads, ports, and banks to support the cotton trade.

- Global Textile Industry: The surge in cotton production due to the gin had a ripple effect worldwide. Affordable cotton fueled the growth of the global textile industry. Cotton clothing, previously a luxury good, became more readily available, impacting fashion trends. This shift is documented in the writings of fashion historians like Caroline Cummings, who notes the rise of lighter, more breathable clothing styles made possible by affordable cotton.

The Bad:

- Fueling the Expansion of Slavery: Undoubtedly, the cotton gin’s darkest impact was its contribution to the expansion of slavery. While the South relied on slave labor before the gin, its newfound efficiency made cotton cultivation even more profitable. This fueled a demand for more enslaved people, leading to a brutal internal slave trade within the US. Historian Walter Johnson, in his book “Soul by Soul”, estimates that the number of enslaved people in the US increased by over 1 million between 1790 and 1820, largely due to the cotton boom.

- Moral Dilemma and the Road to Civil War: The cotton gin’s impact exposed a stark moral dilemma for the young nation. The economic prosperity of the South, heavily reliant on slave labor, came at a horrific human cost. The debate over slavery intensified, dividing the nation along regional lines and ultimately contributing to the outbreak of the Civil War.

The Debate Continues:

The legacy of the cotton gin remains a topic of debate among historians. Was it a catalyst for economic progress or a tool that entrenched a system of oppression? Perhaps the answer lies somewhere in between. The South’s dependence on slave labor predated the gin, but the invention undeniably amplified the problem.

Unique Perspective: It’s crucial to consider the counterfactual – what if the cotton gin hadn’t been invented? While the South might have remained less economically prosperous, the expansion of slavery and the resulting Civil War might have been averted.

Cotton Gin and the Industrial Revolution

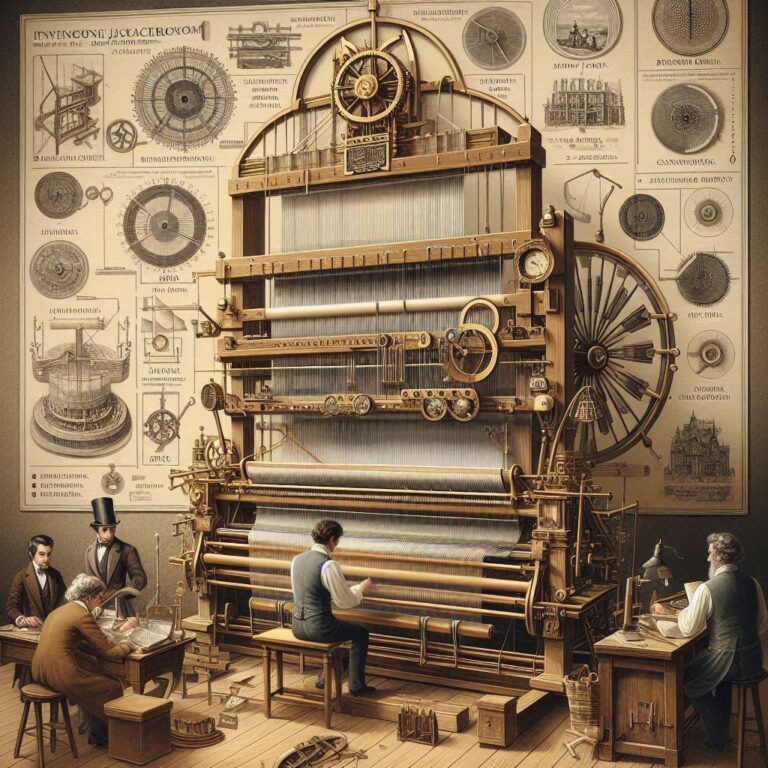

The Industrial Revolution, a period of rapid technological advancement and industrialization, swept across Europe and North America in the late 18th and early 19th centuries. While inventions like the steam engine and power loom are often at the forefront of discussions, the seemingly simple cotton gin played a crucial, and somewhat unexpected, role in propelling this era of change.

Beyond Textiles: A Catalyst for Change: Unlike its European counterparts, the Industrial Revolution in the United States had a unique flavor. Here, the cotton gin, primarily focused on agriculture, became a key driver. Data compiled by the National Bureau of Economic Research reveals that cotton production in the U.S. skyrocketed by a staggering 1,600% between 1790 and 1820 following the invention of the cotton gin. This surge in production had a ripple effect across the American economy.

Feeding the Textile Beast: The increased availability of cheap, processed cotton fueled the booming textile industry in the North. Northern textile mills, equipped with power looms, were able to mass-produce cotton cloth at a much faster rate. This abundance of affordable textiles transformed clothing from a luxury item to a more accessible commodity, impacting fashion trends and consumer behavior across the nation.

Take, for instance, the city of Lowell, Massachusetts. Nicknamed the “Spindle City,” Lowell boomed as a textile manufacturing center in the early 1800s. Fueled by the steady supply of cotton from the South, Lowell’s textile mills employed thousands of workers, primarily young women, and churned out vast quantities of cotton cloth. This rise of textile centers like Lowell illustrates the far-reaching impact of the cotton gin beyond the cotton fields.

However, the cotton gin’s influence transcended the economic sphere. While it fueled industrial growth, it also exacerbated the institution of slavery in the South. The increased demand for cotton cultivation led to a surge in the slave population, creating a complex and morally reprehensible dynamic within the American experiment.

Exploring Further:

The cotton gin serves as a reminder that the Industrial Revolution wasn’t a homogenous phenomenon. In the American context, it intertwined with existing social realities, highlighting the complex interplay between technological innovation, economic growth, and human exploitation. By understanding the multifaceted impact of the cotton gin, we gain a richer perspective on this pivotal period in history.

Cotton Gin Facts (Interesting Trivia)

- Fashion Revolution: Before the gin, cotton clothing was a luxury good due to the high cost of processing the fibers. The gin’s efficiency made cotton far more affordable, leading to a shift towards lighter, more breathable clothing styles, particularly for undergarments and summer wear. This trend is documented in the book “Denim: Fashion’s Frontier” by Emily W. B. de la Breteigne, which highlights the rise of denim clothing made from affordable cotton.

- Patent Battles: Eli Whitney’s patent on the cotton gin was fiercely contested by other inventors, including Phineas Miller and Hodgen Holmes. These legal battles, documented in court records of the time, highlight the fierce competition surrounding this transformative technology. While Whitney ultimately prevailed, the legal battles delayed his financial gains from the invention.

- Beyond Cotton: The ginning principle wasn’t limited to cotton. Variations of the gin were later developed to process other fibrous materials like flax, hemp, and even wool. These adaptations broadened the impact of the ginning technology on the textile industry.

By understanding the multifaceted impact of the cotton gin, we gain a deeper appreciation for its role in shaping American history. It serves as a reminder of the complex interplay between technological innovation, economic forces, and the enduring challenges of human morality.

Conclusion

The cotton gin invention is far more than just an invention. It’s a narrative of ingenuity, economic transformation, and a dark stain on American history. Eli Whitney’s simple machine revolutionized the textile industry, but its impact extended far beyond cotton fields. It fueled the rise of “King Cotton” in the South and the relation between the cotton gin and slavery.

The cotton gin’s legacy continues to be debated. Was it a catalyst for progress or a symbol of exploitation? Perhaps the answer lies somewhere in between. Regardless, its transformative power on the 19th century and its ongoing role in today’s textile industry remain undeniable.

But the story doesn’t end here. The cotton gin’s evolution raises questions about the ethical considerations of technological innovation. As we look towards the future, what ethical frameworks can we employ to ensure that our inventions empower all of humanity, not just a select few?

We invite you to delve deeper. Explore the complex history of cotton and the cotton gin. Consider the ethical considerations of technological advancements. Let this story spark further conversation and reflection on the impact of innovation throughout history.

“If you enjoyed this exploration of the cotton gin’s legacy, I encourage you to check out my other blog posts that delve into fascinating topics related to history and technology!”