Introduction: Why Wedges Matter in Everyday Life

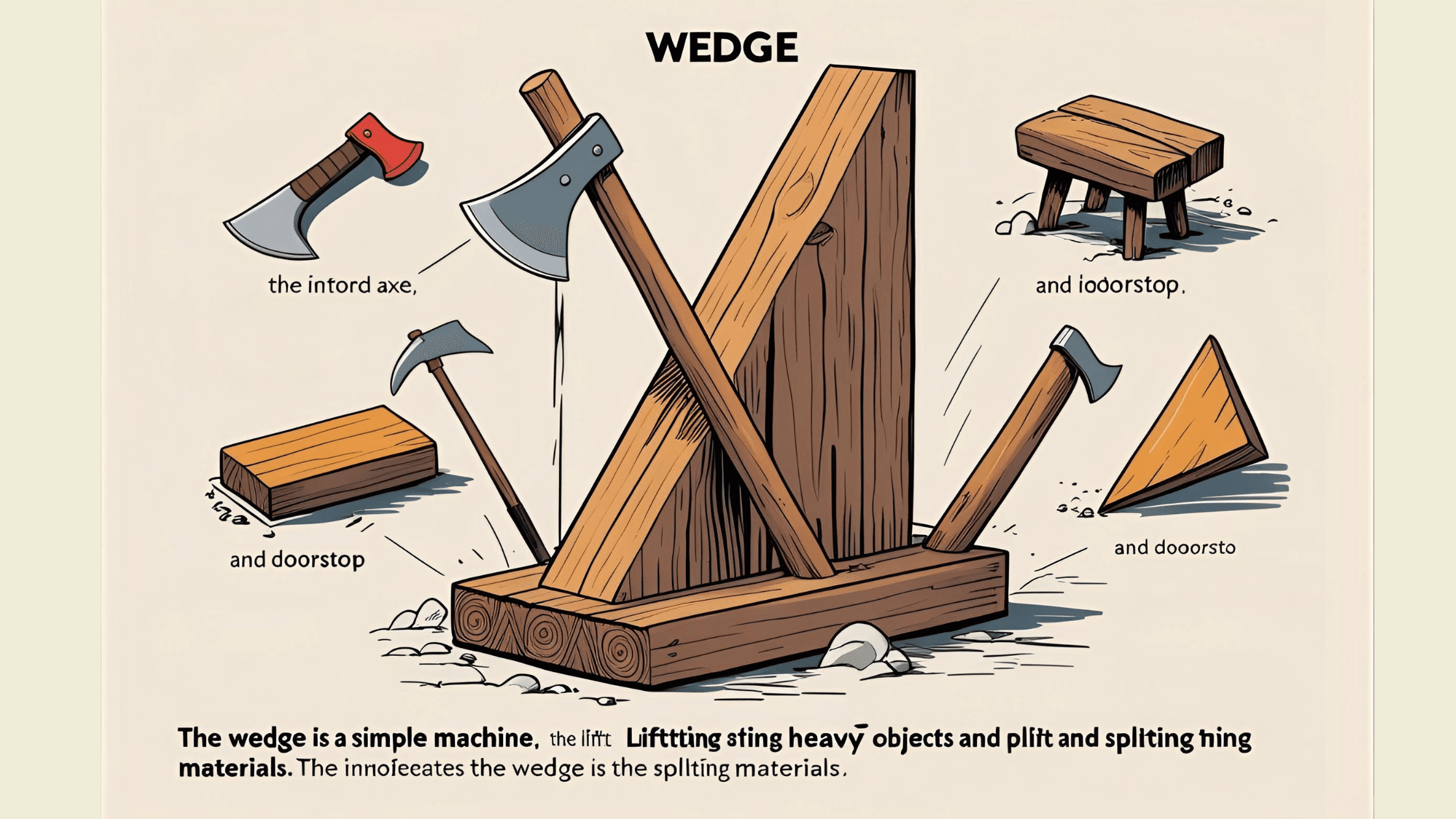

Imagine you’re out camping and need to split logs for a fire. You try snapping a thick piece of wood with your bare hands—no luck. You stomp on it, but it won’t budge. Then, you grab an axe. One powerful swing, and the log splits cleanly in two. This moment perfectly illustrates the power of a simple machine wedge—a tool that transforms brute strength into targeted force.

But what is a wedge, really? A wedge is a triangular tool that belongs to the six classical simple machines, along with the lever, pulley, wheel and axle, screw, and inclined plane. Unlike machines that lift or move loads, the wedge is designed to redirect and concentrate force, making it ideal for splitting, cutting, or separating materials.

The importance of wedges throughout history is undeniable. Ancient builders used stone wedges to shape enormous blocks for pyramids and temples. In today’s world, wedges are everywhere—from surgical scalpels that make clean incisions to chisels that shape wood with incredible precision. They’re the unsung heroes behind the scenes in construction, healthcare, cooking, and mechanical work.

Real-Life Applications of Wedges:

- Cutting: Knives, scissors, surgical blades

- Splitting: Axes, log splitters, ice picks

- Lifting/Separating: Doorstops, crowbars, chisels

- Securing: Nails, staples, tacks (act as mini wedges resisting pull-out)

Beyond utility, wedges also offer a physics advantage. Through the concept of wedge mechanical advantage, a longer, narrower wedge can multiply force while requiring less input effort. This principle helps explain why sharper blades cut better and thinner axes split logs more efficiently.

In fact, when comparing wedge vs inclined plane, you’ll find they share a similar foundation—the wedge is essentially an inclined plane in motion. But instead of moving loads upward, it forces materials apart.

So, the next time you slice vegetables, hammer in a nail, or watch a construction crew split timber, take a moment to appreciate the science and ingenuity behind the wedge. Understanding how it works doesn’t just satisfy curiosity—it reveals the elegance of engineering in everyday life.

What Is a Wedge?

Shaped like a narrowing triangle, a wedge is a simple machine that channels force into a sharp edge to split, lift, or slice through objects. When you push on the wide end, the energy is directed toward the pointed edge, allowing it to break through materials more efficiently.

In simple terms:

A wedge is a tool that makes it easier to cut or separate objects by focusing applied force into a smaller area.

From a physics standpoint, a wedge is a moving inclined plane. While an inclined plane helps you raise objects by distributing force over distance, the wedge does the reverse: it applies force outward or downward to divide materials. This makes it particularly effective when precision and penetration are needed.

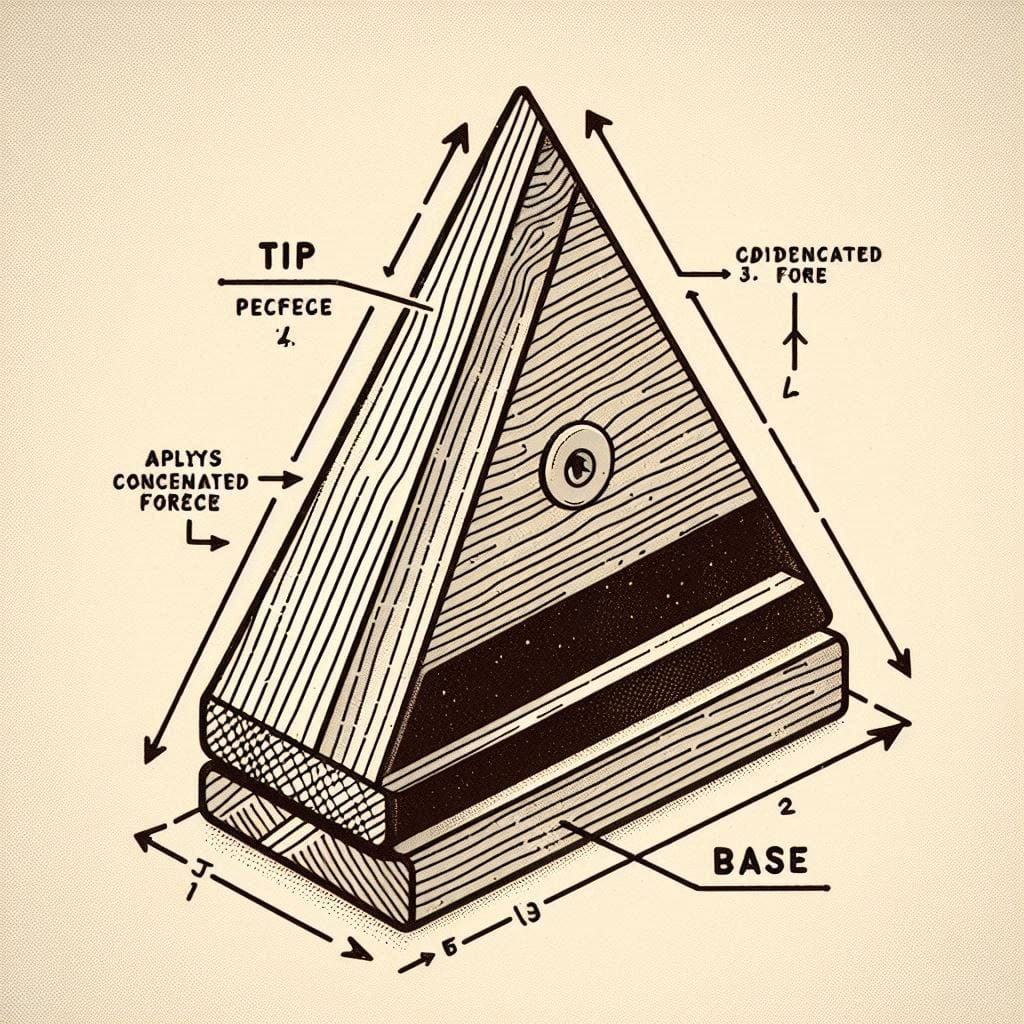

Wedge Shape Explained:

Here’s a basic visual to understand a wedge’s shape and function:

The sharper the wedge’s angle, the more efficiently it cuts — but it also requires more distance to travel through the material. This trade-off is crucial in designing tools for different tasks.

Common Examples of Wedges in Daily Life:

| Tool | Purpose | How It Uses Wedge Principle |

|---|---|---|

| Axe | Splitting wood | Concentrates downward force to separate fibers |

| Knife | Cutting food or fabric | Thin edge slices through material |

| Chisel | Carving or shaping hard surfaces | Drives into a surface and pushes it apart |

| Nail | Joining materials | Pierces with minimal surface resistance |

| Plow | Farming – turning over soil | Cuts and lifts earth as it moves forward |

| Doorstop | Holding a door open or shut | Prevents movement by creating opposing force |

Real-World Insight:

Let’s say you’re designing a kitchen knife. A sharper wedge angle will slice more cleanly but may dull faster. A steeper wedge may last longer but require more effort to cut. Engineers and designers play with wedge angles and materials depending on the task — from scalpels to snowplows.

This deeper understanding of the wedge simple machine definition helps us appreciate why certain tools are shaped the way they are, and why their functionality is tied directly to this classic physics principle.

How a Wedge Works: Physics & Force Multiplication

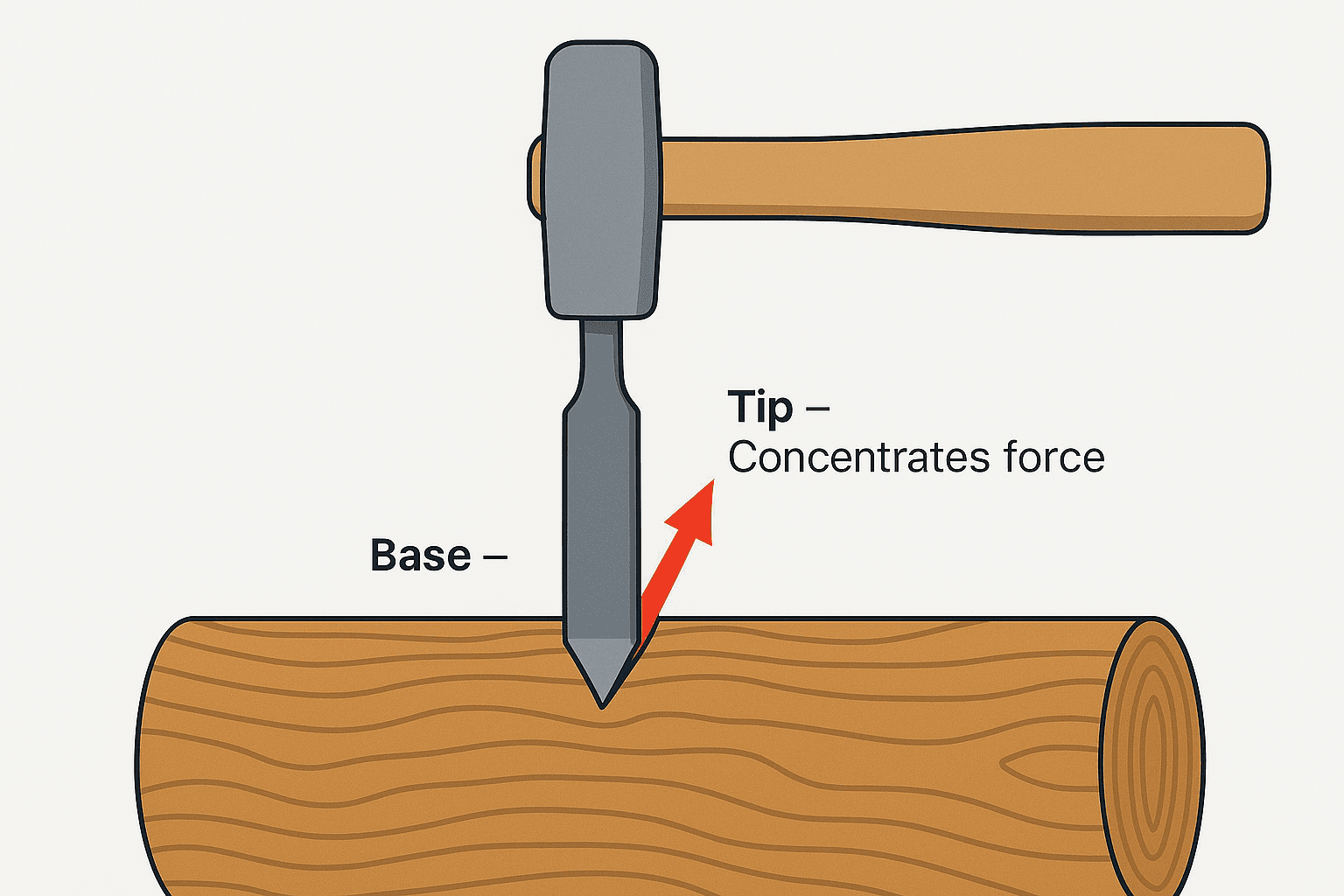

To understand how a wedge works, picture this: when you press a knife into an apple, you’re applying a downward force. But the result isn’t just vertical — the apple splits apart sideways. A wedge works its magic by turning a single force into a spreading force that splits or lifts.

Force Redirection and Splitting

A wedge takes the force you apply on its base and transforms it into outward or sideward forces that push material apart. This is why wedges are used to cut, split, or pry — they don’t just pierce material; they separate it.

Imagine pressing a nail into wood. You’re pushing downward, but the nail’s slanted sides redirect that force outward, parting the wood fibers. Similarly, an axe splits a log by using downward force that is redirected laterally.

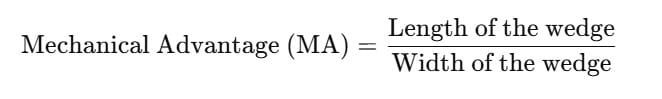

Mechanical Advantage of a Wedge

The mechanical advantage (MA) of a wedge tells us how effectively it multiplies your input force. A higher MA means less effort is needed to do the same work.

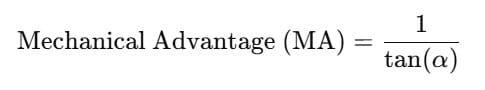

There are two formulas for calculating the wedge mechanical advantage, depending on how you measure the wedge:

- Based on Length and Width:

- Based on the Angle (α):

Where:

- α = the angle of the wedge’s tip

- Smaller angles = Higher mechanical advantage

Step-by-Step Example:

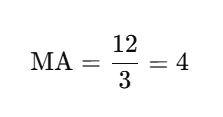

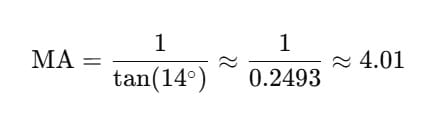

Let’s say you have a wedge that’s:

- Length = 12 cm

- Width = 3 cm

- Tip Angle (α) = 14°

Using Formula 1:

This means your wedge multiplies force by 4 times — if you apply 10 N of force, it generates 40 N of output force at the tip.

Using Formula 2 (with angle):

✅ The smaller the angle or the thinner the wedge, the higher the wedge mechanical advantage — but it may require more distance to drive in.

🔑 Key Insights:

- Wedges convert applied force into sideways pressure, making it easier to split or lift materials.

- Mechanical advantage (MA) measures how much a wedge amplifies your effort — the higher the MA, the less force you need.

- A longer wedge with a narrower angle increases mechanical advantage, reducing effort but requiring more distance.

- Trade-off alert: Sharper wedges cut better but can deform or wear down more quickly under stress.

Real-World Limitations and Efficiency Factors

While the theoretical mechanical advantage of a wedge might sound perfect on paper, real-world conditions introduce losses and limitations. Understanding these helps in designing better tools and using them more effectively.

Friction in Wedges

Friction is a double-edged sword in wedge mechanics:

- Good friction prevents the wedge from slipping out (e.g., a doorstop).

- Bad friction wastes energy by turning useful motion into heat and drag.

In a real application, some of your input force is lost to friction between the wedge and the material. This reduces the actual mechanical advantage.

Material Type and Resistance

The effectiveness of a wedge depends heavily on the material it’s being used on:

- Soft materials (like butter or softwood) require less force.

- Hard or fibrous materials (like hardwood, bone, or metal) require more force and can increase wear on the wedge.

A steel chisel, for example, is much more effective on wood than on stone without reinforcement or proper design.

Wear and Sharpening Needs

Wedges work best when sharp. Over time, edges:

- Become dull due to repeated use

- May chip or deform depending on the hardness of both the wedge and the target material

This leads to lower efficiency, requiring:

- More force to achieve the same output

- Frequent sharpening for cutting wedges (knives, axes, chisels)

Wedges with poor maintenance can lose up to 30–40% of their effective performance.

Efficiency vs Ideal Mechanical Advantage

Let’s say a wedge has an ideal MA of 6. That’s what physics tells us under perfect conditions.

But due to:

- Friction losses

- Blunt edges

- Material resistance

…the actual mechanical advantage might be only 3.5–4.5 in real use.

This is why understanding wedge efficiency is critical in fields like engineering, construction, and surgery. Tools must be optimized not just for design but for real-world performance.

More than a simple triangle, the wedge is a force amplifier that delivers big results from small input. But like any machine, its real-world performance depends on the environment, materials, and maintenance.

Everyday and Industrial Applications of Wedges

The wedge is more than just a triangular piece of metal or wood — it’s a timeless tool that has evolved from prehistoric stone to robotic precision systems. Understanding how wedges function in both daily life and industry reveals just how versatile and powerful this simple machine truly is.

🏺 Ancient Uses of the Wedge

Humans have used wedges for over 2.5 million years. Early stone tools were essentially primitive wedges — shaped and sharpened for survival.

Key Ancient Applications:

- Bronze Wedges: Used in ancient Egypt and Mesopotamia for stone splitting during construction of temples and tombs.

- Wood Splitting: Timber workers used wooden or metal wedges to split logs into planks or firewood.

- Stone Carving: Sculptors used chisels and hammer-driven wedges to shape statues, monuments, and architectural elements.

These early tools show that even before modern machines, people leveraged examples of wedges to build civilizations.

🛠️ Wedges in Daily Life

Wedges surround us in everyday activities, often unnoticed. From the kitchen to the classroom, these tools help us perform simple and essential tasks.

Common Examples of Wedges in Daily Life:

| Tool | Use Case |

|---|---|

| Knife | Slicing food, opening packages |

| Scissors | Cutting paper, fabric |

| Nail | Fastening wood or walls |

| Stapler pin | Binding pages |

| Peeler | Skinning fruits/vegetables |

| Doorstop | Holding doors in place |

These tools demonstrate how the wedge in daily life provides both force multiplication and precision for tasks that would otherwise require much more effort.

⚙️ Wedges in Industry

Modern industries rely on wedges not just for basic cutting and splitting — but for robotics, automation, and surgical precision.

Industrial Use Cases:

- Chisels and Plane Blades: Woodworking machines and carpentry tools use industrial-grade wedges to remove layers with precision.

- Log splitters harness hydraulic power and steel wedges to slice through heavy timber in mere seconds.

- Mining & Drilling: Wedges are used in rock fracturing tools to break through geological layers.

- Metal Forming: Wedge dies shape sheet metal in manufacturing plants.

- Surgical Tools: Devices like scalpels and biopsy punches use miniaturized wedges to cut tissue cleanly and safely.

- Robotic Grippers: Advanced robots use wedge-shaped end effectors for gripping, lifting, and manipulating objects.

In each case, the wedge in industry adapts to modern needs, scaling from millimeter precision in medical devices to tons of force in heavy machinery.

Wedge vs Inclined Plane vs Screw

All three — wedge vs inclined plane, and screw — belong to the family of simple machines, but they operate differently and serve distinct functions. Understanding these differences helps clarify when to use each one and why.

Definitions: wedge vs inclined plane, and screw

| Simple Machine | Definition |

|---|---|

| Wedge | A tool that splits, cuts, or separates materials by redirecting force. |

| Inclined Plane | A sloped surface that allows objects to be raised or lowered with less force. |

| Screw | A spiral inclined plane that converts rotational motion into linear force. |

Practical Analogies:

| Tool/Use Case | Machine Type | Real-Life Example |

|---|---|---|

| Knife | Wedge | Cutting vegetables |

| Ramp | Inclined Plane | Pushing a cart up a slope |

| Drill Bit | Screw | Driving screws into wood |

Function Differences:

| Feature | Wedge | Inclined Plane | Screw |

|---|---|---|---|

| Primary Motion | Linear | Linear | Rotational |

| Force Direction | Redirects outward | Up/down a slope | Converts torque to push/pull |

| Use Case | Cutting/Splitting | Lifting heavy objects | Fastening, pressing, drilling |

| Mechanical Advantage | Depends on angle and length | Depends on slope steepness | Depends on pitch and radius |

Example Comparison:

- Wedge (e.g., chisel)

- Pushes downward

- Force is redirected sideways to split wood

- Inclined Plane (e.g., ramp)

- Pushes forward and upward

- Useful for lifting objects gradually

- Screw (e.g., bottle cap or bolt)

- Rotates to create compression or tension

- Holds things tightly together

When to Use Each:

| Task | Best Machine |

|---|---|

| Cutting, splitting | Wedge |

| Lifting heavy loads | Inclined Plane |

| Tight fastening or drilling | Screw |

Understanding wedge vs inclined plane vs wedge vs screw distinctions equips students and engineers to choose the right tool or mechanism for the job.

How to Use Wedges Safely and Effectively

While wedges are incredibly useful, improper usage can lead to accidents, tool damage, or reduced efficiency. Whether you’re a DIY enthusiast, student, or industrial worker, following proper technique and precautions ensures you’re using wedges effectively while staying safe.

✅ Proper Alignment Matters

The direction of force and the way a wedge is positioned significantly impacts performance and safety.

Align the wedge straight with the material grain (e.g., wood grain) for smoother, cleaner splits.

Misalignment can lead to:

- Slipping

- Uncontrolled material breakage

- Bent or damaged wedges

Always ensure the base of the wedge is firmly in contact with the surface before applying force.

🔪 Keep the Wedge Sharp

A sharp edge is not just more effective — it’s also safer. A dull wedge requires more force, increasing the risk of slips or uncontrolled movements.

Maintenance Tips:

- Regularly inspect cutting wedges (knives, chisels, axes) for dullness or chips.

- Use proper sharpening stones or machines suited to the tool type.

- Store wedges in dry places to avoid rust or corrosion.

Remember, sharp tools cut clean; dull tools cause danger.

📐 Choosing the Right Wedge Angle

Different materials require different wedge geometries for best performance.

| Material Type | Recommended Wedge Angle |

|---|---|

| Soft materials (e.g., softwood, foam) | Narrow angle (10°–20°) for precision cutting |

| Hard materials (e.g., hardwood, metal) | Wider angle (25°–40°) for durability & control |

| Splitting logs | Thick, wide wedge with blunt tip to withstand impact |

Selecting the correct wedge ensures you’re using wedges effectively while minimizing tool stress and maximizing output force.

🧤 Safety Gear Checklist

Never underestimate the potential hazards of working with wedges — especially in carpentry, metalwork, or industrial settings.

Here’s a basic wedge safety tips checklist:

✅ Safety goggles – Protect your eyes from chips, sparks, or flying debris

✅ Cut-resistant gloves – Maintain grip and prevent hand injuries

✅ Steel-toed boots – Especially important in outdoor or industrial environments

✅ Ear protection – When using wedges with loud equipment like splitters or drills

✅ Stable work surface – Avoid uneven or shaky platforms

⚠️ Pro Tip:

Always stand to the side of the driving direction (not directly behind the wedge), especially when using a hammer or sledge — this prevents injury in case the wedge deflects.

FAQ

What is a wedge in simple machines?

A wedge is a type of simple machine that consists of two inclined planes joined together to form a sharp edge. It is used to split, cut, or lift objects by applying force over a larger surface area and concentrating it at the sharp end. Common examples include knives, axes, chisels, and nails.

How does a wedge make work easier?

The wedge makes work easier by converting a force applied over a wide surface into concentrated force at a narrow edge. This means less effort is needed to split or cut an object. For example, when you push an axe into wood, the wedge shape directs the force sideways, splitting the wood apart.

What are everyday examples of wedges?

You use wedges more often than you realize. Examples include: Knives and scissors (cutting food, paper, fabric). Axes and chisels (splitting wood, shaping stone). Nails, pins, and needles (penetrating surfaces). Shovels and plows (digging soil). Even your teeth act like natural wedges for biting and chewing food.

What is the difference between a wedge and an inclined plane?

Both are simple machines, but their use is different: Inclined plane: Helps move objects up or down with less effort by spreading force over distance (like a ramp). Wedge: A moving inclined plane that cuts, splits, or lifts objects by concentrating force at a point. So, while an inclined plane stays stationary, a wedge moves through an object.

What are the advantages and disadvantages of using a wedge?

Advantages: Reduces effort needed for cutting and splitting. Simple design, easy to use. Found in countless tools and natural systems. Disadvantages: Wedges can dull or break over time. Higher force is needed if the wedge is blunt or wide. Friction can reduce efficiency in some materials.

How are wedges used in modern technology?

Beyond basic tools, wedges are crucial in many fields: Construction & engineering: Excavator teeth, rock splitters, cutting machinery. Medical field: Scalpels and surgical blades. Transportation: Aircraft wings and ship hulls use wedge-like shapes to reduce air or water resistance. Everyday life: From zipper teeth to doorstops, wedges quietly power many inventions.

🧠 Conclusion: Small Tool, Big Impact — The Power of the Wedge

From ancient temples to high-tech robotics, the simple machine wedge has proven that even the most basic tools can revolutionize how we live, build, and work. Though small in size, wedges deliver enormous value—quietly powering industries, solving everyday problems, and turning force into function with elegant simplicity.

🔁 Recap: Why Wedges Still Matter Today

In this guide, we explored what a wedge really is—not just a triangular tool, but a powerful machine that:

- Redirects input force into outward splitting force

- Appears in everyday tools like knives, axes, chisels, and doorstops

- Offers measurable wedge mechanical advantage based on shape and angle

- Varies in effectiveness depending on sharpness, material, and friction

Together, these points reinforce the importance of wedges in science, design, and daily problem-solving.

👀 Look Around — Wedges Are Everywhere

Wedges are hiding in plain sight. Once you know how they work, spotting wedge simple machine uses becomes second nature. For example:

- That sharp kitchen knife slicing veggies? It’s a wedge.

- Your doorstop keeping the breeze out? Wedge.

- The blade in your pencil sharpener? Another wedge at work.

This tool may be ancient, but its utility is timeless.

🧪 Optional Hands-On Activity

DIY Wedge Demo for Classrooms or Curious Minds:

Split a soft bar of soap using two tools:

- A flat, dull object (like a ruler)

- A sharp plastic knife

Observe how the wedge angle and sharpness impact the cut. It’s a simple experiment that visually explains wedge mechanical advantage and force concentration—perfect for students learning about simple machines.

💡 Final Thought: Wedge vs Inclined Plane – and Beyond

Remember, a wedge is essentially a moving inclined plane. But while an inclined plane helps move loads upward, a wedge focuses force to split, cut, or separate. When comparing wedge vs inclined plane, the key difference lies in motion and application—yet both are brilliant uses of basic physics.

So whether you’re an engineer, educator, or simply fixing something at home, understanding what is a wedge gives you insight into one of the most clever and essential tools ever created. And now that you know how to use it more effectively, you’re better equipped to solve problems smarter—not harder.

🧭 Explore More Simple Machines

Now that you’ve explored the power of the simple machine wedge, why stop there?

Check out these in-depth guides to complete your understanding of all six classical simple machines:

-

🔗 Simple Machine – Pulley

Discover how pulleys lift heavy loads with minimal effort using rope and wheel systems. -

🔗 The Screw – A Fundamental Simple Machine

Learn how this spiral invention converts rotational motion into powerful linear force. -

🔗 Unleashing the Power of Levers

Find out how levers help lift, pry, and balance with minimal input. -

🔗 Simple Machines – Wheel and Axle

Explore how wheels reduce friction and revolutionized transport and tools.