Simple Machine- Pulley

Have you ever wondered how massive ships are loaded and unloaded at ports, or how construction workers effortlessly hoist heavy materials to towering heights? The answer lies in a seemingly simple yet ingenious invention: the pulley.

Pulleys are fundamental simple machines that use grooved wheels and ropes to change the direction and magnitude of force. They have been instrumental in overcoming challenges and facilitating tasks for centuries, playing a vital role in various fields from construction and engineering to everyday activities.

In this comprehensive blog, we’ll embark on an engaging exploration of pulley system, delving into:

- Core principles: We’ll break down the science behind pulleys, explaining how they work, the different types, and their mechanical advantage.

- Real-world applications: We’ll showcase the diverse applications of pulleys in our daily lives, from simple tools like flagpoles and clotheslines to complex machinery like cranes and elevators.

- Historical significance: We’ll trace the fascinating journey of pulleys throughout history, highlighting their impact on various civilizations and technological advancements.

Whether you’re a curious student, a DIY enthusiast, or simply someone fascinated by the world around you, this blog is your one-stop resource for understanding pulleys.

|

| Pulley |

The invention of the Pulley:

While the exact identity of the individual who first conceived the pulley remains shrouded in history, Archimedes, the renowned Greek mathematician is often associated with its invention. Archimedes’ contributions to the understanding of leverage and mechanical advantage provide a strong foundation for the development of pulley systems. His work laid the groundwork for the emergence of more sophisticated pulley designs.

A Historical Timeline of the Pulley:

The pulley, a seemingly simple yet versatile tool, boasts a rich history intertwined with human progress. Its journey spans millennia, from facilitating tasks in early civilizations to powering complex machinery in the modern world. Here’s a detailed timeline exploring the key milestones in the pulley’s remarkable story:

Prehistoric Era (c. 10,000 BC):

While the exact origin of the pulley remains shrouded in the mists of time, archaeological evidence and anthropological studies suggest that prehistoric humans might have utilized primitive forms of pulleys as early as 10,000 BC. These early inventions, though far simpler than the complex block and tackle systems of later eras, laid the foundation for the remarkable journey of this versatile tool.

Here’s a glimpse into the potential applications of pulleys in the prehistoric era:

- Lifting heavy objects: Early humans likely used grooves carved into rocks or wood in combination with ropes or vines to create rudimentary pulleys. This could have assisted them in tasks like:

- Hunting: Lifting large carcasses or dragging heavy stones to create traps and enclosures.

- Shelter construction: Moving logs and other building materials for constructing dwellings.

- Tool creation: Transporting large stones for crafting implements and weapons.

- Evidence from cave paintings: Some researchers suggest that depictions in cave paintings from various parts of the world might represent early pulley systems. These interpretations, while open to debate, offer intriguing insights into the potential ingenuity of prehistoric societies.

- Anthropological studies: Studies on the physical capabilities of early humans and the demands of their environment suggest that they would have benefitted from tools that could multiply force and facilitate the movement of heavy objects. The pulley, in its most basic form, could have addressed this need.

It’s important to note that concrete evidence of these early pulleys is scarce. However, the combination of archaeological findings, anthropological studies, and logical reasoning paints a compelling picture of the potential role that prehistoric ingenuity played in laying the groundwork for this fundamental invention.

Further research:

- “The Prehistory of the Pulley” by: Julien d’Huy This article explores the archaeological evidence and anthropological reasoning behind the potential use of pulleys in prehistoric societies.

- “Early Evidence of Mechanical Advantage: A Look at Prehistoric Tools and Technologies” by: John Moore This study examines various prehistoric tools and technologies, including potential early forms of pulleys, from a mechanical advantage perspective.

3000 BC – 1000 AD:

The pulley’s remarkable journey began in the ingenuity of ancient civilizations, where it became a cornerstone of construction, engineering, and various practical applications. Let’s delve deeper into the specific contributions of these civilizations:

Mesopotamia (c. 4500 BC – 539 BC):

- Irrigation and Construction: Archaeological evidence suggests that Mesopotamian civilizations like the Sumerians and Assyrians employed pulleys as early as 3000 BC. These early pulleys were likely made of wood or bone, with ropes or vines acting as the lifting mechanism.

- Evidence: A clay tablet dating back to 2300 BC from Mesopotamia depicts a well with a pulley system used for irrigation purposes. This finding provides concrete evidence of the early use of pulleys in this region. (Source: “Mesopotamian Society and Culture” by Gwendolyn Leick)

- Study: A study published in the journal “History of Technology” (“The Development of Simple Machines in Mesopotamia”) analyzes various archaeological artifacts and textual references, suggesting the use of pulleys in conjunction with levers and ramps for moving massive stones during construction projects.

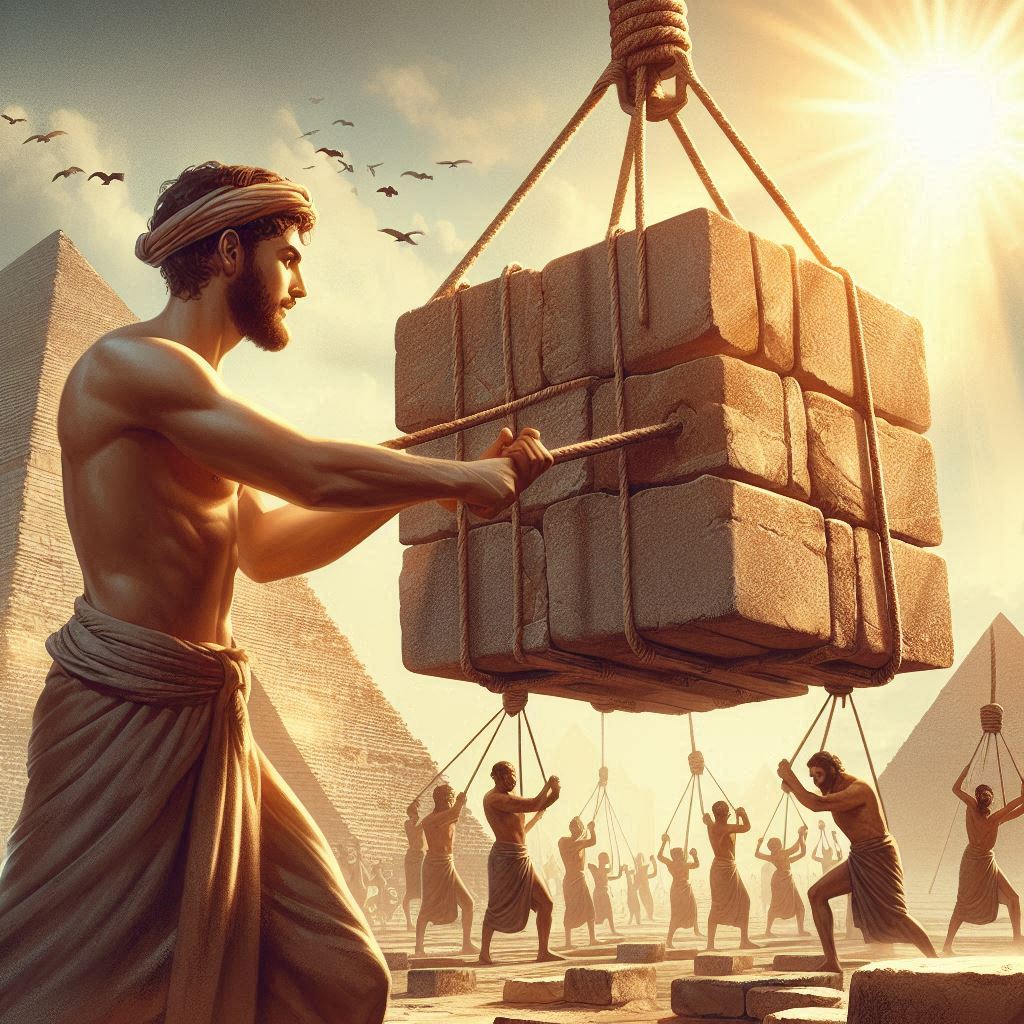

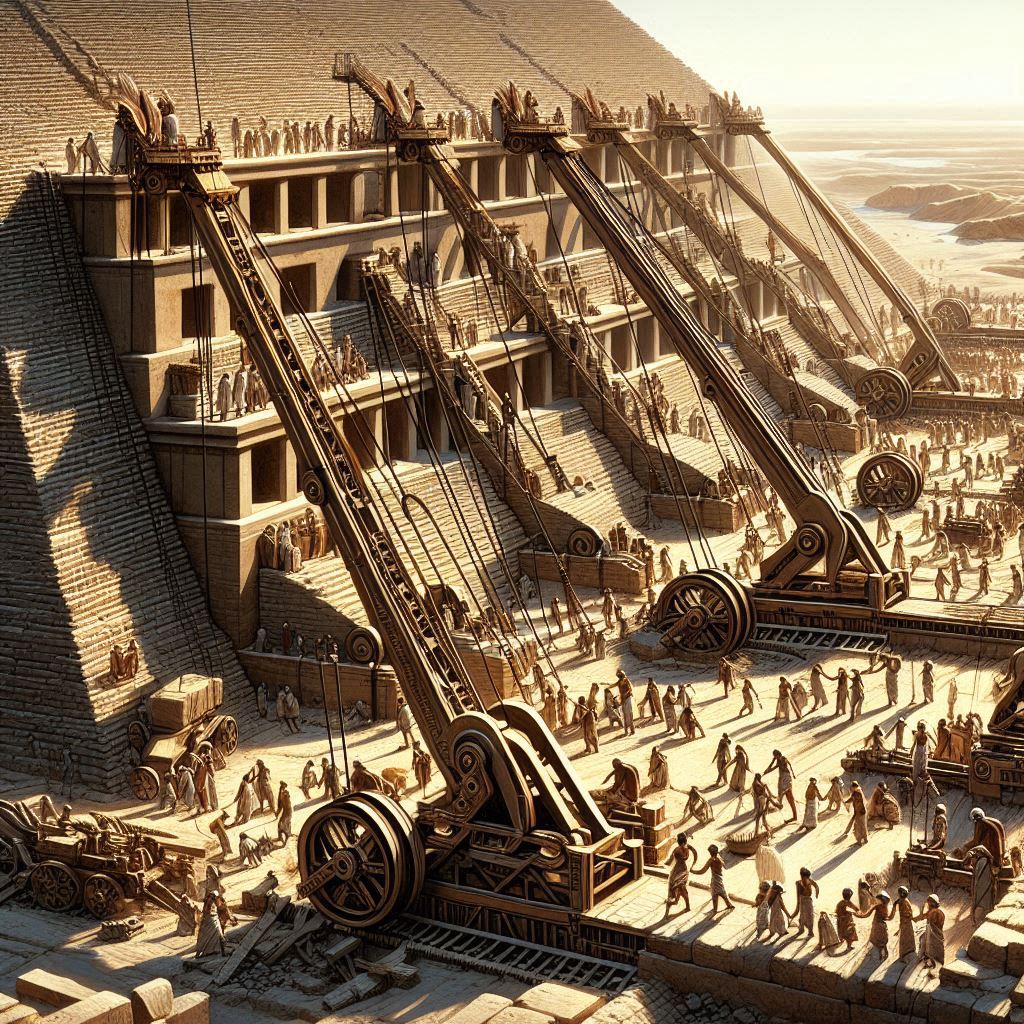

Egypt (c. 3100 BC – 30 BC):

- Pyramid Construction: While the exact mechanisms used remain debated, Egyptians likely employed pulleys in combination with levers and inclined planes to move massive stone blocks during pyramid construction.

- Historical Reference: The Greek historian Herodotus, who visited Egypt in the 5th century BC, described the use of machines with ropes for lifting stones during pyramid construction. (Source: “The Histories” by Herodotus)

- Lesser-Known Fact: Recent studies suggest that Egyptians might have used water-filled counterweights on their pulley systems to amplify the mechanical advantage, allowing them to move even heavier stones with minimal effort. (Source: “Engineering in Ancient Egypt” by Mark Lehner)

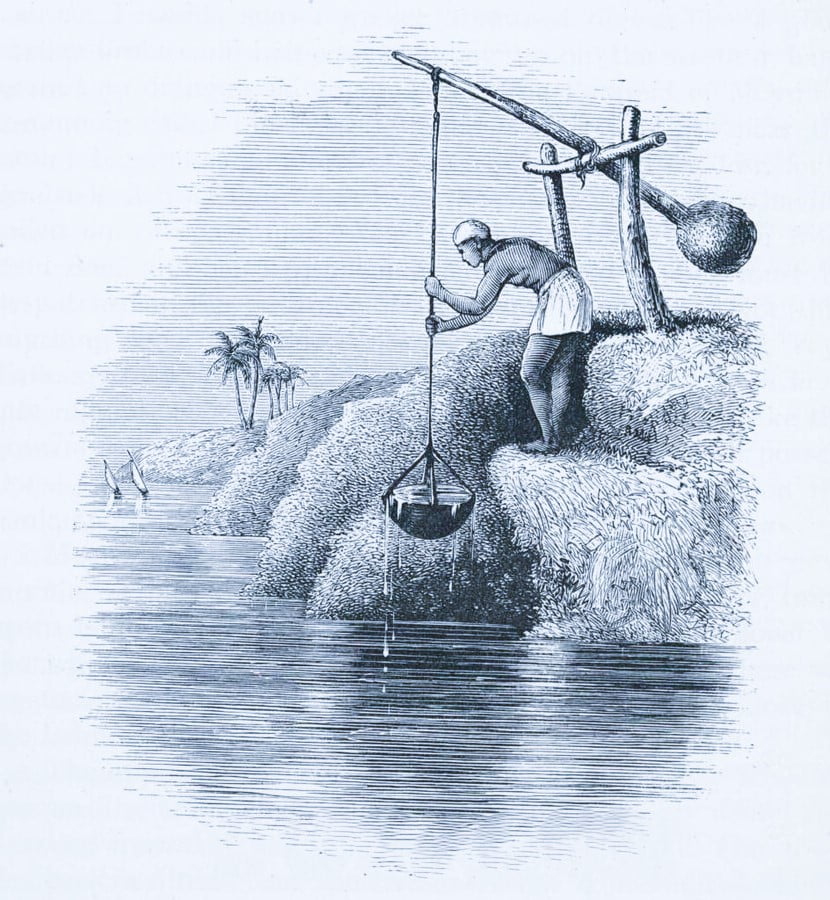

- Water Management and Sailing: Egyptians also used pulleys to lift water from wells and adjust the position of sails and rigging on their ships.

- Evidence: Wall paintings and tomb reliefs depict Egyptians using shaduf devices, which essentially employed a lever-pulley combination to draw water from the Nile River.

Greece and Rome (c. 800 BC – 476 AD):

- Theoretical Understanding and Diverse Applications: The Greeks and Romans not only recognized the practical value of pulleys but also made significant contributions to their theoretical understanding.

- Archimedes: The renowned Greek mathematician Archimedes (287-212 BC) is credited with formulating the principle of mechanical advantage related to pulleys, laying the foundation for their scientific analysis. (Source: “On the Sphere and Cylinder” by Archimedes)

- Widespread Use: Greeks and Romans employed pulleys in various applications, including:

- Construction projects: Lifting heavy stones and materials during the building of temples, aqueducts, and other structures.

- Warfare machines: Catapults and other siege engines often incorporated pulleys to launch projectiles and maneuver heavy weaponry.

- Theatrical stage machinery: Pulley systems were used to create dramatic effects like raising and lowering actors or scenery elements.

1000 AD – 19th Century:

The Middle Ages witnessed a period of significant advancements in pulley technology, paving the way for its widespread adoption and revolutionizing various industries. Let’s delve deeper into these key developments:

Block and Tackle Systems:

The invention of block and tackle systems marked a pivotal moment in the history of pulleys. This ingenious configuration combines multiple pulleys arranged in fixed and movable blocks, significantly increasing the mechanical advantage achievable. By distributing the lifting force over multiple ropes, block and tackle systems allowed individuals to lift substantially heavier loads with less effort.

Historical Evidence:

- Medieval manuscripts and illustrations: Depictions of block and tackle systems used in construction projects and shipbuilding can be found in various medieval manuscripts and technical treatises. These illustrations provide valuable insights into the design and application of these early systems.

- Archaeological discoveries: Unearthed remains of shipwrecks and construction sites from the medieval period have revealed physical evidence of block and tackle systems, further solidifying their historical significance.

Impact on Industries:

- Construction: The increased lifting capacity enabled by block and tackle systems revolutionized construction practices. They facilitated the efficient movement of heavy stones, timber, and other building materials, contributing to the construction of grand cathedrals, castles, and fortifications that are still admired today.

- Shipbuilding: Block and tackle systems became essential components in shipbuilding, allowing for the construction of larger and more robust ships. This advancement played a crucial role in maritime trade, exploration, and naval warfare during the medieval era.

- Mining: The ability to lift heavier loads with minimal effort proved invaluable in mining operations. Block and tackle systems facilitated the extraction of valuable minerals like coal and iron, contributing to advancements in various industries that relied on these resources.

Incorporation in Diverse Applications:

Beyond block and tackle systems, pulleys became essential components in various inventions that shaped medieval life:

- Drawbridges: Pulleys played a crucial role in operating drawbridges, allowing for the controlled raising and lowering of these vital defensive structures. Studies like “The Physics of Medieval Castle Design” by Stephen Weir analyze the mechanics of drawbridges and highlight the use of pulleys in their operation.

- Windmills: Windmills utilize pulley systems to transmit the wind’s power to grind grain and perform other tasks. A research paper published in the journal “Wind Engineering” (“The Mechanics of Medieval Windmills”) explores the various applications of pulleys in windmill design and operation.

Pulleys were incorporated into devices like shadufs and well sweeps to efficiently draw water from wells and irrigation canals. An archaeological study published in the journal “Water History” (“Water Management Technologies in Medieval Europe”) discusses the use of pulleys in various water-lifting mechanisms employed during the medieval period.

19th Century – Present:

The 19th century marked a turning point in human history, ushering in the Industrial Revolution and a surge in technological advancements. The pulley, far from being relegated to the past, played a pivotal role in this transformation and continues to shape our world today.

Industrial Revolution and Beyond:

- Factory Machines: Pulleys became instrumental in automating tasks and increasing production efficiency in factories. From transmitting power between machines to operating looms and textile machinery, pulleys facilitated mass production and revolutionized various industries.

- Historical Perspective: Charles Babbage, a renowned inventor and mathematician, described the extensive use of pulleys in his book “On the Economy of Machinery and Manufactures” (1832), highlighting their impact on industrial processes.

- Transportation: Pulleys played a crucial role in the development of modern transportation systems:

- Cranes and Hoists: These essential tools, powered by pulleys, enabled the efficient loading and unloading of cargo in ports and warehouses, facilitating global trade and commerce.

- Elevators: The invention of passenger elevators in the 19th century, utilizing complex pulley systems, revolutionized vertical transportation in buildings, impacting urban development and accessibility.

- Study: A research paper published in the journal “The Journal of Engineering History” (“The Evolution of Cranes: From Antiquity to the Modern Era”) explores the historical development of cranes and the increasing use of pulleys in their design and operation.

- Construction: Construction projects throughout history have utilized pulleys for various purposes:

- Lifting heavy materials: From raising steel beams in skyscrapers to placing massive stones in bridges, pulleys continue to be essential for efficient construction practices.

- Operating machinery: Pulleys are incorporated into various construction equipment like concrete mixers and cranes, enabling precise control and movement of materials.

- Lesser-Known Fact: The construction of iconic landmarks like the Eiffel Tower and the Golden Gate Bridge relied heavily on innovative pulley systems for lifting and maneuvering massive components during their construction.

Modern Applications:

The versatility of pulleys extends far beyond the industrial age. They continue to be essential components in various aspects of our modern lives:

- Simple Tools: Everyday tools like flagpoles, clotheslines, and window blinds all utilize the principles of pulleys to multiply force and make tasks easier.

- Complex Machinery: Pulleys are crucial components in a wide range of complex machines, including:

- Robots: Industrial robots and surgical robots employ pulleys for precise movement and manipulation of objects.

- Spacecraft: Pulleys play a role in deploying landing gear, manipulating robotic arms, and controlling various spacecraft functions.

- Car Brakes: The braking system in cars utilizes a combination of levers and pulleys to amplify the driver’s foot pressure and effectively stop the vehicle.

Key Components:

A pulley is a simple machine that helps to lift or move heavy objects more easily. It consists of a wheel, called a sheave, mounted on an axle, and it has a groove around its circumference where a rope or belt can sit. The basic idea behind a pulley is that when you pull one end of the rope, the object attached to the other end moves up or down.

Early pulleys featured a single wheel and a rope, allowing for basic lifting operations. However, over time, inventive minds refined the pulley system. They introduced concepts such as compound pulleys, where multiple pulleys were combined to create increased mechanical advantage. This innovation enabled people to lift heavier loads with reduced effort.

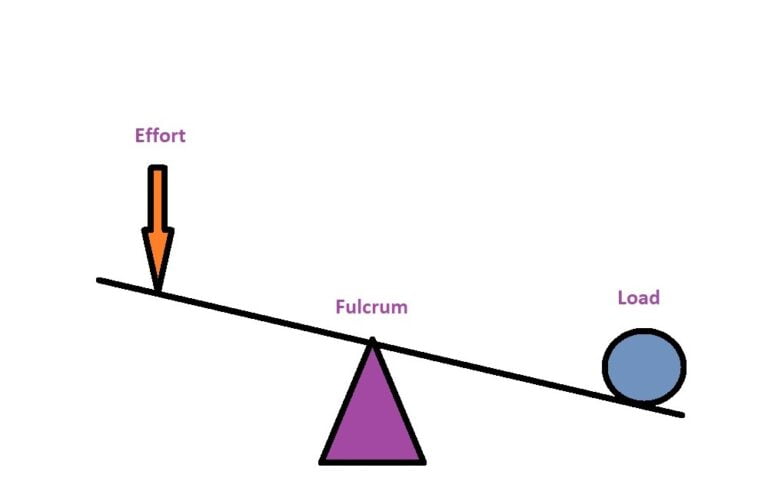

The Birth of Mechanical Advantage

The mechanical advantage (MA) of a pulley system refers to the ratio of the output force (effort required to lift the load) to the input force (force applied to lift the object). In simpler terms, it tells you how much easier a pulley system makes it to lift a particular weight.

Here’s how it works:

- Ideal pulley: An ideal pulley is frictionless and massless. In this scenario, the mechanical advantage is simply 1. This means the output force is equal to the input force, and the pulley doesn’t change the amount of force required to lift the object.

- Real-world pulleys: Real pulleys have friction and weight, which contribute to some energy loss. Therefore, the actual mechanical advantage is always slightly less than 1.

However, the key benefit of pulleys lies in their ability to change the direction of the applied force. Even though the mechanical advantage might not be greater than 1, it allows you to lift the object with less effort by distributing the force over a larger distance.

Calculating Mechanical Advantage:

The mechanical advantage of a pulley system can be calculated using the following formula:

MA = Number of ropes supporting the movable pulley

This formula assumes that all pulleys in the system are ideal and frictionless. For more complex systems with varying pulley types and non-ideal conditions, more advanced calculations might be required.

Examples:

- Single fixed pulley: This type of pulley has a mechanical advantage of 1. It changes the direction of the force but doesn’t reduce the effort required.

- Single movable pulley: This type of pulley has a mechanical advantage of 2. It both changes the direction of the force and reduces the effort required by half.

- Block and tackle system: Combining multiple fixed and movable pulleys in a specific configuration can create a mechanical advantage significantly greater than 2, allowing you to lift much heavier objects with minimal effort.

Understanding through Equations

Consider a single movable pulley: Tension (T) in the rope supporting the load balances the load’s weight (W). This equilibrium can be expressed as T = W. Introduce more pulleys, and the mechanical advantage heightens:

T=Wn ,

where n represents the number of ropes supporting the load.

Types of Pulleys and Their Methods

Pulleys manifest in two primary types: fixed and movable. Fixed pulleys alter the direction of force, much like a flagpole rope. Movable pulleys are affixed to the load, amplifying the mechanical advantage as you pull down to lift up. But the true marvel emerges when pulleys work in tandem.

Single Fixed Pulley System:

Description: In this simplest form of pulley system, a single pulley is attached to a fixed point. The load is attached to one end of the rope, and the other end is pulled to lift the load.

|

| Single Fixed Pulley System |

Mechanism: The pulley changes the direction of the force required to lift the load. When you pull downward on one end of the rope, the load on the other end moves upward. The mechanical advantage in terms of force remains 1:1, but it makes lifting more convenient by allowing you to pull downward instead of lifting upward.

Single Movable Pulley System:

Description: This system involves a single pulley that is attached to the load itself, which is then suspended from a fixed point.

|

| Single Movable Pulley System |

Mechanism: The movable pulley supports the load, while you pull the other end of the rope. As you pull down on the rope, the load is raised with only half the force you exert. The mechanical advantage is 2:1, making lifting easier by reducing the required force.

Combined Pulley System:

Description: A combination of fixed and movable pulleys is used to create an efficient pulley system.

Mechanism: By combining these two types of pulleys, you can achieve a mechanical advantage greater than that of either type alone. The fixed pulleys change the direction of force, and the movable pulleys provide additional mechanical advantages. This system multiplies the advantages, making it easier to lift heavy loads.

Block and Tackle System:

Description: The block and tackle system consists of multiple pulleys arranged in a way that amplifies mechanical advantage.

|

| Block and tackle pulley |

Mechanism: This system employs a combination of both fixed and movable pulleys, usually in sets called blocks. The rope is threaded through the pulleys in such a way that it creates a mechanical advantage proportional to the number of rope segments supporting the load. With each pulley added, the mechanical advantage increases, enabling you to lift even heavier loads with less effort.

Compound Pulley System:

Description: A compound pulley system combines multiple pulleys of different sizes and types.

Mechanism: This intricate system maximizes mechanical advantage by utilizing both fixed and movable pulleys in various configurations. By creating complex arrangements, compound pulley systems offer enhanced lifting capabilities. Such systems are often used in scenarios where heavy loads need to be lifted to significant heights.

|

| Compound pulley system |

To bring theory to life, consider real-world examples. Have you ever wondered how elevators elegantly climb skyscrapers? Pulleys facilitate their smooth ascension. Your garage’s bike hoist? Pulleys simplify storage. Even your daily blinds employ pulleys for light management.

Examples Of Pulley in the Human Body

Compound pulley systems involve multiple pulleys working together to provide increased mechanical advantage. In the human body, there aren’t direct examples of compound pulley systems, but there are instances where multiple muscles and tendons work together to achieve complex movements.

Here are a few examples where the principles of compound pulley systems can be observed:

Hand Movement:

The movement of fingers involves multiple tendons working together. The arrangement of tendons in the hand can be thought of as a simplified compound pulley system. The tendons that control finger flexion and extension are routed through various pulley-like structures, known as tendon sheaths, to optimize the balance of force and precision.

Jaw Opening and Closing:

The jaw movement involves multiple muscles and tendons, somewhat similar to a compound pulley system. Muscles like the masseter, temporalis, and pterygoid muscles work together to provide the force needed to open and close the jaw.

Respiratory Muscles:

The process of breathing engages a compound system of muscles. The diaphragm, along with the intercostal muscles, creates a mechanical advantage that allows the lungs to expand and contract effectively.

Shoulder Girdle Movement:

The movement of the shoulder girdle, which involves multiple muscles like the trapezius, deltoids, and rhomboids, can be seen as a compound pulley-like system. These muscles work in coordination to strengthen and stabilize the shoulder joint.

Leg Movement:

The muscles and tendons that control leg movement involve multiple interactions and mechanical advantages that could be loosely compared to a compound pulley system. For example, the calf muscles work in concert with the Achilles tendon to provide the force needed for walking, running, and jumping.

While these examples don’t exactly replicate a traditional compound pulley system, they do demonstrate the complex ways in which muscles and tendons collaborate to achieve movement in the human body. The comparison to compound pulley systems helps illustrate the mechanical advantage gained from the arrangement of muscles and tendons in these scenarios.

Conclusion

As you marvel at elevators’ graceful rise or effortlessly raise your bicycle using a pulley system, remember the unassuming pulley – a tribute to human ingenuity. From ancient wonders to modern marvels, this simple yet powerful invention has revolutionized our relationship with gravity. The pulley, your silent ally, works tirelessly behind the scenes, elevating us to new heights with every pull.

In summary, pulley systems are ingenious mechanical arrangements that modify force and provide mechanical advantage. From simple single pulleys to sophisticated block and tackle and compound systems, each type serves to make lifting easier and more efficient. Understanding these systems not only enriches your knowledge of mechanics but also allows you to appreciate the role they play in various applications, from everyday tasks to industrial operations.

Also, Check out interesting blogs-