10 sustainable building materials

Construction is one of the largest contributors to global carbon emissions, with materials like cement and concrete at the forefront of this environmental impact. Cement production alone accounts for approximately 8% of the world’s carbon dioxide emissions. Traditional materials, while durable, have significant ecological drawbacks, such as resource depletion, energy-intensive manufacturing, and waste generation.

In response, the construction industry is undergoing a transformation, with a growing focus on eco-friendly building materials that reduce environmental harm. From natural building materials to lighter concrete alternatives, these innovations aim to lower the carbon footprint while maintaining or even enhancing functionality. This blog highlights 10 sustainable building materials that are shaping the future of construction and explores their potential to replace or supplement conventional materials like cement.

Hempcrete: A Revolutionary Natural Building Material

What is Hempcrete?

Hempcrete is a bio-composite material created by mixing the inner woody core of the hemp plant, known as hurds, with a binder like lime and water. This combination produces a lightweight, breathable, and durable material ideal for eco-conscious construction. Unlike traditional concrete, which is dense and rigid, hempcrete is flexible and less prone to cracking under stress.

Why is Hempcrete Sustainable?

Hempcrete’s sustainability stems from several unique features:

- Carbon-Negative Production: Hempcrete absorbs significant amounts of CO₂ during the hemp plant’s growth, offsetting emissions generated during production and transport. Studies show that one cubic meter of hempcrete can sequester approximately 165 kg of CO₂.

- Fast-Growing Resource: Hemp grows in as little as four months and thrives in a variety of climates with minimal water and no need for pesticides or synthetic fertilizers.

- Soil Improvement: Hemp plants improve soil health by adding nutrients and preventing erosion, making them a regenerative crop for farmers.

- Waste Reduction: Hempcrete is biodegradable at the end of its lifecycle, unlike conventional materials that contribute to landfill waste.

Applications of Hempcrete

- Insulation: Due to its thermal properties, hempcrete excels as wall insulation, regulating indoor temperatures efficiently.

- Prefabricated Blocks: Builders increasingly use hempcrete blocks as an alternative to concrete for non-load-bearing walls.

- Roofing Panels: Its lightweight nature makes hempcrete ideal for roofs in low-energy housing projects.

- Retrofitting Historic Structures: Hempcrete’s breathable quality prevents trapped moisture, making it perfect for restoring old buildings.

How Hempcrete Outperforms Traditional Materials

Hempcrete acts as a “breathable” building material, allowing moisture to escape while maintaining excellent thermal performance. This unique property prevents mold and mildew, which are common issues with conventional insulation. Furthermore, it has high fire resistance due to the lime binder and its low density.

Challenges of Using Hempcrete

Despite its many advantages, hempcrete has limitations:

- Structural Strength: Hempcrete is not load-bearing and requires a structural frame, such as wood or steel, to support buildings.

- Cost and Availability: Hempcrete production is not yet widespread, making it more expensive and harder to source than conventional materials.

- Regulatory Hurdles: Legal restrictions on hemp farming in certain countries limit its adoption, though this is changing as attitudes toward hemp improve globally.

Why Hempcrete is a Lighter alternative for cement

Hempcrete is significantly lighter than traditional concrete, weighing about one-eighth of its density. This makes it easier to transport and handle, reducing labor and logistical costs. Its low density also provides superior acoustic insulation, further adding to its appeal for sustainable construction.

Hempcrete stands out prominently on any eco-friendly material list, recognized as one of the most versatile natural building materials available today. As a lighter concrete alternative, it redefines the concept of sustainability by offering a carbon-negative solution for modern construction needs. Hempcrete is a prime example of innovation within the realm of 10 sustainable building materials, setting a new benchmark for eco-friendly building materials.

Cross-Laminated Timber (CLT)

What is it?

Cross-Laminated Timber (CLT) is an innovative engineered wood product composed of multiple layers of timber boards glued together in alternating directions. This cross-layered arrangement ensures structural integrity, durability, and enhanced dimensional stability compared to standard timber.

Why it’s sustainable:

CLT is a renewable material sourced from forests that are sustainably managed, ensuring its minimal environmental impact. Unlike steel and concrete, its production process is less energy-intensive and emits significantly less carbon. It also acts as a carbon sink, storing CO₂ captured by trees during their growth, thus actively reducing greenhouse gas levels. Using CLT as an alternative for cement and steel in structural applications offers a sustainable pathway to reducing the construction industry’s environmental footprint.

Applications:

- Structural components: CLT is widely used for walls, floors, and roofs in homes, offices, and large-scale commercial buildings.

- High-rise buildings: Recent projects showcase CLT in tall wooden structures, demonstrating its strength and feasibility as a replacement for steel and concrete.

- Prefabrication: CLT panels are easy to fabricate and transport, allowing for efficient construction with minimal on-site waste.

Modern advancements have addressed fire safety, a common concern with wooden materials. CLT panels char on the outside, creating a protective barrier that shields inner layers from damage, meeting strict fire resistance standards. Additionally, its lightweight nature reduces transportation costs while maintaining impressive load-bearing capacity, making it competitive with conventional materials. This evolution positions CLT among the most promising natural building materials for modern construction needs.

Rammed Earth

What is it?

Rammed earth is an eco-friendly construction method that compacts a blend of soil, clay, sand, and stabilizing agents like lime into molds to create solid, durable walls. The process creates solid, durable walls that are structurally sound and have a high thermal mass. These earth-based walls are typically reinforced with modern tools and machinery to ensure precision, durability, and fast construction.

Why it’s sustainable:

Rammed earth is renowned for its exceptionally low environmental footprint. It uses natural building materials, and locally sourced materials, reducing the need for transportation and industrial processing. This results in a much lower carbon footprint compared to traditional construction materials like concrete or steel. The soil used in rammed earth walls is abundant and renewable, and the technique requires little energy for production, making it a highly sustainable option. Additionally, the thermal mass of rammed earth helps maintain consistent indoor temperatures, reducing the need for artificial heating or cooling and lowering energy consumption.

Rammed earth’s environmental benefits extend to its lifespan. These walls are incredibly durable and can last for centuries with proper care, making it a long-term solution that avoids the constant need for repairs and replacements associated with other building materials. Unlike conventional cement-based options, which emit large quantities of carbon dioxide during production, rammed earth significantly reduces carbon emissions, making it an essential part of the growing movement towards eco-friendly building materials.

Applications:

- Foundations and walls: Rammed earth is particularly well-suited for use in foundations, walls, and retaining structures. It offers excellent stability and strength.

- Thermal mass structures: Thanks to its high thermal mass, rammed earth is used to create buildings that are energy-efficient, reducing the need for air conditioning in summer and heating in winter.

- Aesthetic design: In addition to its functional applications, rammed earth offers a unique and natural aesthetic. Its earthy tones and textures integrate beautifully with modern architecture, making it a sought-after material for eco-conscious designers.

- Landscaping: It can also be used in creating walls, pathways, and garden features, blending seamlessly into natural surroundings.

Unique Angle:

One of the most compelling aspects of rammed earth is its ability to integrate seamlessly with modern architecture while retaining a rustic, organic charm. The growing trend of incorporating natural materials into contemporary design has seen rammed earth emerge as a leading choice for both residential and commercial construction. Newer techniques have improved the material’s weather resistance, ensuring that it remains a viable option in a variety of climates. Furthermore, the visual appeal of rammed earth—its unique textures and natural appearance—has made it increasingly popular for aesthetic-driven designs. Rammed earth is ideal for those seeking eco-friendly building materials that don’t compromise on beauty, strength, or sustainability. By utilizing this technique, architects can design buildings that are in harmony with nature while maintaining modern standards of comfort and efficiency.

Bamboo

What is it?

Bamboo is a fast-growing grass that has been used as a building material for centuries, particularly in regions like Asia and South America. It is renowned for its strength, flexibility, and sustainability. The plant reaches maturity in just 3-5 years, far quicker than traditional timber, making it an incredibly renewable resource. Bamboo can be used in its natural form for scaffolding, flooring, and even structural elements, or processed into engineered products such as laminated bamboo beams and plywood.

Why it’s sustainable:

Bamboo’s sustainability is primarily due to its rapid growth cycle. It is one of the fastest-growing plants on Earth, capable of reaching full maturity in just a few years, making it a highly renewable natural building material. When harvested, bamboo regenerates from its roots without the need for replanting, making it a highly efficient resource, and alternative for cement. Unlike hardwood trees that take decades to mature, bamboo can be harvested and replenished continuously, minimizing deforestation pressures.

Bamboo’s ability to sequester carbon is another key advantage. During its growth, it absorbs significant amounts of carbon dioxide, contributing to a reduction in atmospheric carbon levels. When used in construction, bamboo also acts as a carbon sink, continuing to store CO₂ in the material after it has been harvested and processed. This makes bamboo an attractive alternative to conventional materials like concrete and steel, which are energy-intensive and produce substantial carbon emissions during production.

Additionally, bamboo is biodegradable, meaning it doesn’t contribute to long-term waste when it reaches the end of its useful life. Its minimal processing requirements also ensure that its environmental impact remains low, reinforcing its position as a natural building materials.

Applications:

- Scaffolding: Bamboo is widely used in Asia for scaffolding, providing a lightweight yet strong framework for construction.

- Flooring and panels: Processed bamboo can be made into durable flooring, panels, and tiles for both residential and commercial spaces.

- Structural elements: Due to its high strength-to-weight ratio, bamboo is increasingly used in the construction of load-bearing structures. It is particularly useful for lightweight frameworks, roofs, and even entire buildings in certain contexts.

- Furniture and decor: Bamboo is also used for furniture, partitions, and decorative elements, adding an eco-friendly aesthetic to interiors.

Bamboo is often compared to steel in terms of its tensile strength. When processed and engineered correctly, bamboo is capable of bearing loads that rival some of the strongest traditional building materials. This unique characteristic has led to bamboo’s adoption in the construction of alternative for cement applications, particularly in countries with abundant bamboo resources. Bamboo’s flexibility also makes it an ideal material for earthquake-resistant buildings, which has made it a popular choice in regions prone to seismic activity.

Bamboo as a renewable resource plays a crucial role in modern sustainable construction. It’s one of the most promising materials for creating eco-friendly buildings due to its strength, versatility, and minimal environmental impact. As we seek to reduce our reliance on concrete, bamboo offers a sustainable, cost-effective, and biodegradable alternative that meets the needs of both builders and eco-conscious homeowners. This versatile material is not only a great option for sustainable building, but it also plays a vital role in shifting the construction industry towards a more sustainable future.

Ferrock

What is it?

Ferrock is a revolutionary alternative for cement made from recycled steel dust and other industrial by-products. This innovative material is produced by combining steel dust with silica, water, and a small amount of carbon-rich substances to form a hardened, rock-like material. What sets Ferrock apart is that it actually absorbs carbon dioxide during its curing process, unlike traditional cement, which is a major emitter of carbon dioxide.

Why it’s sustainable:

Ferrock is considered carbon-negative, which means it not only avoids emitting CO₂ but also captures and stores it. The production of conventional cement involves heating limestone to high temperatures, which generates significant amounts of carbon emissions. Ferrock, on the other hand, absorbs CO₂ from the atmosphere during its creation, making it a far more eco-friendly alternative. This process happens as the steel dust reacts with silica and CO₂, forming mineral compounds that lock carbon into the material. This characteristic allows Ferrock to sequester up to five times more CO₂ than is emitted during its production, making it a truly sustainable alternative for cement.

Additionally, Ferrock is known to be stronger and more durable than traditional cement, thanks to the steel dust’s high tensile strength. This superior strength allows for paving, foundations, and underwater construction, which are some of the most demanding applications for any building material.

Applications:

- Paving and roads: Ferrock’s strength and durability make it an excellent choice for road construction and paving. Its carbon-absorbing properties also make it an environmentally friendly option for infrastructure.

- Foundations: Used in foundation work, Ferrock’s long-term durability makes it ideal for structures requiring long-lasting support.

- Underwater construction: Due to its superior water resistance, Ferrock is increasingly being used in marine environments, where traditional concrete might deteriorate due to exposure to water and salt.

- Building structures: In addition to heavy-duty applications, Ferrock can be used for building structural components in eco-friendly housing projects.

Ferrock’s ability to absorb CO₂ during production is a game-changer for the construction industry. This unique process not only makes it a sustainable building material but also actively contributes to reducing the carbon footprint of the built environment. Unlike traditional cement, which contributes to greenhouse gas emissions, Ferrock represents an eco-friendly alternative for cement that aids in combating climate change by absorbing carbon from the atmosphere.

Ferrock is a lighter concrete alternative that offers a promising way forward for builders looking to reduce their environmental impact. Its growing popularity in green construction projects is due to its innovative approach to sustainability and its practical applications in a range of construction settings. As a sustainable alternative for cement, Ferrock has the potential to revolutionize the industry by significantly lowering carbon emissions while providing a material that is stronger and more durable than its conventional counterparts.

Straw Bales

What is it?

Straw bales are tightly packed bundles of straw that are used in construction as both insulation and structural support. Straw is an agricultural by-product that is lightweight, readily available, and renewable, making it an ideal material for sustainable building. In the construction process, the bales are stacked together to form walls, which can then be plastered or rendered for durability and aesthetic appeal.

Straw bale construction has been used for centuries, particularly in regions where straw is abundant. The technique was initially popularized in the American Midwest during the late 19th century, but it has seen a resurgence as part of the broader movement toward sustainable construction practices.

Why it’s sustainable:

Straw bales are an incredibly eco-friendly building materials. Not only is straw a renewable resource, but it is also biodegradable, which means it won’t contribute to long-term waste after its use. Straw is one of the most carbon-neutral materials, requiring very little processing compared to other building materials like cement or steel. The production of straw bales leaves behind a minimal environmental footprint, making it an attractive option for builders looking for a natural building material.

Straw bales also offer exceptional insulation properties due to the trapped air within the compacted straw. This natural insulation reduces the need for heating and cooling, which lowers energy consumption and contributes to a building’s overall energy efficiency. Straw bale homes are naturally cool in the summer and warm in the winter, making them ideal for use in passive heating and cooling systems.

Furthermore, the cost-effectiveness of straw bales makes them a highly affordable option, especially in regions where straw is abundant. Straw bale homes are typically cheaper to build than conventional houses, and the material itself is often sourced locally, reducing transportation costs and emissions.

Applications:

- Walls in low-rise buildings: Straw bales are most commonly used for constructing walls in residential buildings, particularly in low-rise and eco-friendly housing projects.

- Eco-homes: Straw bale construction is popular for eco-homes that prioritize sustainability, offering a natural and affordable solution for green building.

- Insulation: In addition to being used as load-bearing walls, straw bales are often utilized as insulation in both residential and commercial buildings.

- Interior design elements: When treated properly, straw bales can also be used in interior walls, creating a natural, rustic aesthetic.

One of the unique aspects of straw bale construction is its effectiveness in passive heating and cooling systems. The insulating properties of straw bales make them ideal for reducing a building’s reliance on artificial climate control systems, which is a significant contributor to energy savings. This makes straw bale construction not only a sustainable choice but also an energy-efficient one.

Straw bales have the added advantage of being biodegradable, ensuring that they will not contribute to landfill waste after their useful life. As natural building materials go, straw bales are often favored for their affordability, insulation properties, and eco-friendliness. While traditional building materials like cement and steel have a much higher carbon footprint, straw bales offer a cost-effective and environmentally friendly alternative for builders seeking to create sustainable, energy-efficient structures.

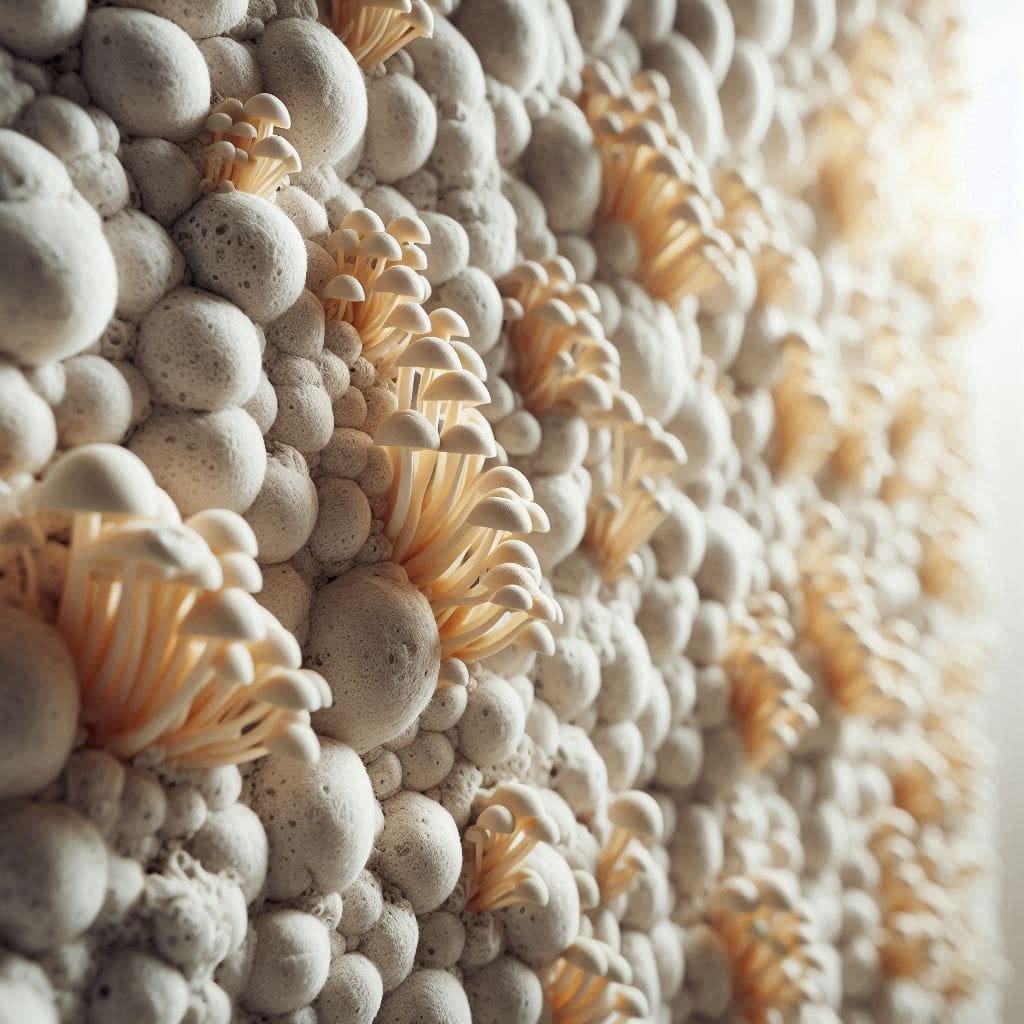

Mycelium Insulation

What is it?

Mycelium insulation is a material made from the root structure of fungi, known as mycelium, which is cultivated and harvested for use in various products. This innovative material is grown using agricultural waste like straw, sawdust, or corn husks, which is then combined with the mycelium to create a sustainable insulation solution. The mycelium’s natural ability to grow and bind these materials together results in a lightweight, durable, and efficient insulation material.

Unlike conventional insulation materials, which are typically made from petroleum-based substances or require significant energy in production, mycelium insulation is grown organically and is completely biodegradable. This makes it an attractive option for eco-conscious builders and designers aiming to reduce the environmental footprint of their structures.

Why it’s sustainable:

Mycelium insulation is a highly sustainable material due to its unique growth process. It utilizes agricultural waste, which would otherwise be discarded, as its primary input. This not only reduces the need for new resources but also diverts waste from landfills, contributing to a circular economy. Mycelium is fully biodegradable, meaning that at the end of its life cycle, it won’t contribute to long-term waste or pollution. The growing process itself also has a minimal carbon footprint, further reinforcing its sustainability credentials.

In addition to being biodegradable, mycelium has natural thermal and acoustic insulating properties, which makes it a high-performance insulation material. When used as insulation in buildings, mycelium helps reduce energy consumption by maintaining consistent internal temperatures, cutting down the need for artificial heating and cooling systems. This contributes to long-term energy savings and reduced carbon emissions.

Applications:

- Insulation panels: Mycelium is primarily used to create insulation panels for walls, floors, and ceilings in residential and commercial buildings. These panels can be customized in terms of density and thickness, depending on the specific insulation needs of the structure.

- Packaging: In addition to building applications, mycelium is also being used for sustainable packaging materials, offering a biodegradable alternative to plastic and Styrofoam.

- Experimental green architecture: Mycelium is still in the early stages of widespread use in construction, but it has begun to gain attention for experimental green architecture. Several architectural projects have explored mycelium for both aesthetic and functional purposes, including its use as wall panels, insulation, and even as an alternative to traditional wood in structural elements.

Mycelium’s role in emerging applications within experimental green architecture highlights its potential to revolutionize the construction industry. With architectural firms pushing the boundaries of sustainable design, mycelium is being explored as part of eco-friendly building materials for use in passive and zero-carbon buildings. The use of mycelium-based insulation not only creates more sustainable buildings but also demonstrates the future potential of bio-based materials in mainstream construction.

As mycelium continues to gain traction as a building material, its integration into eco-friendly construction projects offers a glimpse of the future of natural building materials. Its ability to grow organically and its lightweight insulation properties make it an ideal candidate for eco-conscious architects and builders looking to reduce their carbon footprint.

AshCrete

What is it?

AshCrete is a groundbreaking alternative to traditional Portland cement, made from fly ash, a by-product of coal combustion in power plants. Fly ash is abundant and typically discarded as waste, but when processed and combined with other materials, it can be used to create a concrete-like mixture known as AshCrete. This concrete alternative offers the same strength and durability as conventional cement but with a significantly reduced environmental impact.

AshCrete’s primary component, fly ash, is a fine powder that can replace a portion of the Portland cement used in traditional concrete. By doing so, AshCrete reduces the demand for new cement production, which is one of the most carbon-intensive processes in the construction industry. The use of fly ash in concrete production not only conserves natural resources but also helps to mitigate the environmental issues associated with coal combustion waste.

Why it’s sustainable:

AshCrete is considered a sustainable alternative for cement because it provides multiple environmental benefits. First and foremost, it significantly reduces CO₂ emissions by replacing a portion of the cement, which is a major emitter of greenhouse gases during its production. The production of cement involves heating limestone to high temperatures, which releases carbon dioxide into the atmosphere. By using fly ash in the mix, the need for cement is lowered, leading to a reduction in carbon emissions.

Additionally, AshCrete helps reduce industrial waste by repurposing fly ash, which would otherwise be disposed of in landfills. This reduces the environmental impact of waste disposal, making AshCrete an excellent choice for eco-friendly construction projects. The material also has a longer lifespan than traditional concrete, meaning that it will require fewer repairs and replacements over time, further reducing its environmental impact.

Applications:

- Roads and infrastructure: AshCrete is primarily used in the construction of roads and bridges, where high-strength concrete is needed. Its durability and resistance to wear make it suitable for these high-traffic applications.

- High-strength concrete: AshCrete can be used in a variety of other construction projects, including high-strength concrete used for building foundations, parking structures, and other critical infrastructure.

- Building foundations and slabs: Due to its ability to provide strong structural support, AshCrete is also utilized in foundation work for both residential and commercial buildings.

One of the most exciting aspects of AshCrete is its increasing use in large-scale infrastructure projects such as highways and bridges. Large-scale projects like these traditionally rely heavily on conventional cement, which is energy-intensive and resource-heavy. By adopting AshCrete, these projects can reduce their carbon footprint while still achieving the strength and durability necessary for such infrastructure. This adoption signals a shift in how sustainable building materials are being integrated into construction practices, making AshCrete a viable alternative for major projects looking to embrace green construction principles.

As an alternative for cement, AshCrete stands out for its ability to reduce industrial waste and CO₂ emissions, all while maintaining the performance characteristics of traditional concrete. The material’s potential to be widely adopted in roadways and other large-scale projects makes it an invaluable option for environmentally conscious builders and engineers seeking to minimize their impact on the planet.

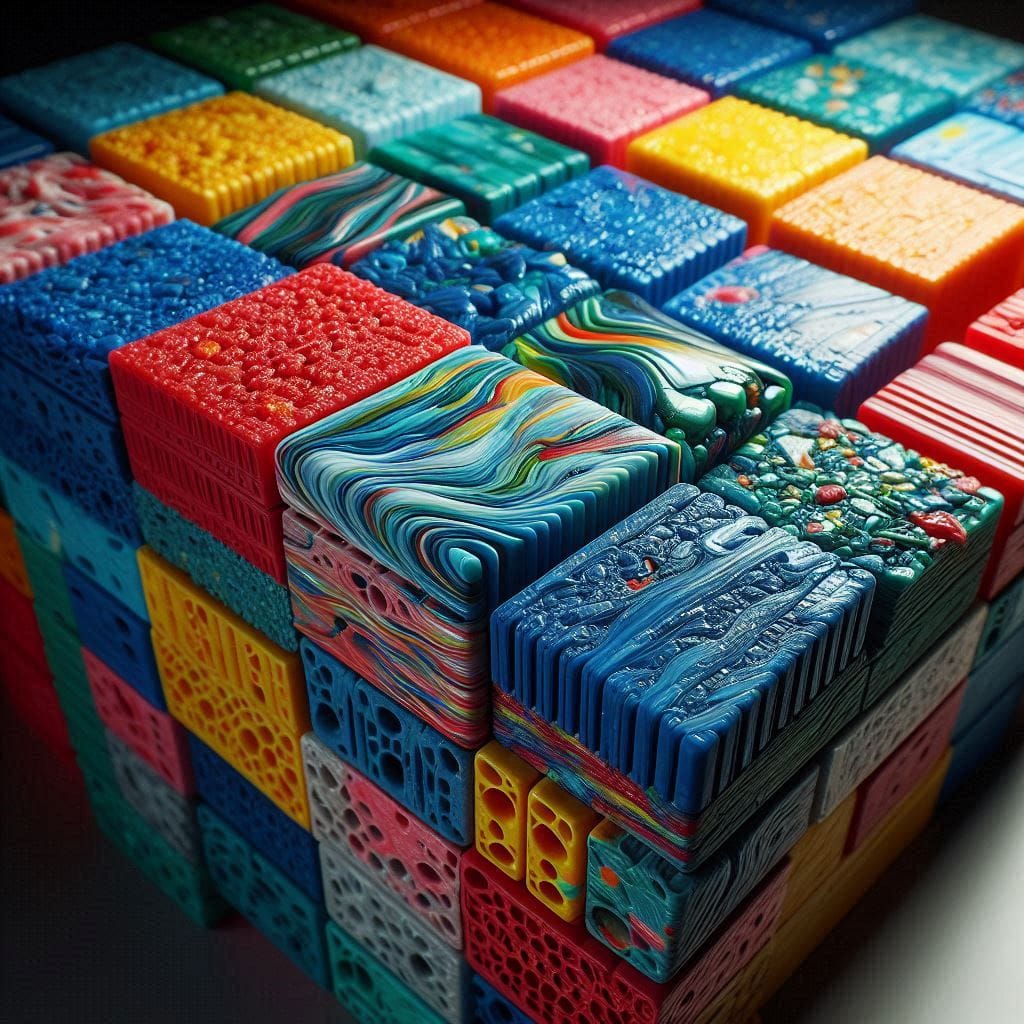

Recycled Plastic Bricks

What is it?

Recycled plastic bricks are innovative building materials made by compressing and molding discarded plastic waste into durable and functional brick-like shapes. This process involves melting down various types of recycled plastic, such as polyethylene or polypropylene, and shaping it into solid bricks. These bricks can be produced in various sizes and shapes, much like traditional clay bricks, making them adaptable for construction purposes. The concept of using plastic waste as a primary material for building structures is gaining traction due to its environmental benefits and practicality.

Why it’s sustainable:

One of the most significant benefits of recycled plastic bricks is their ability to help reduce landfill waste. With the growing global concern about plastic pollution, these bricks offer a way to recycle plastic that would otherwise end up in landfills or oceans. By repurposing plastic waste into construction materials, these bricks help tackle two major environmental challenges: plastic waste and the demand for conventional building materials.

Additionally, plastic bricks offer a durable and lightweight alternative to traditional clay bricks. While traditional bricks are heavy and resource-intensive to produce, plastic bricks are lighter and require less energy to manufacture. Their lightweight nature reduces the carbon footprint associated with transportation and handling during construction. Furthermore, the durability of plastic bricks makes them resistant to common issues like cracking and erosion, which are typical of traditional bricks exposed to harsh weather conditions.

Applications:

- Housing: In regions where access to traditional building materials is limited, recycled plastic bricks are being used to construct homes, providing an affordable and sustainable option. The bricks’ durability and resistance to weather make them ideal for creating structures that can withstand harsh climates.

- Temporary structures: Plastic bricks are also used for building temporary structures such as shelters, storage units, and even disaster relief housing. Their quick assembly and lightweight properties make them an excellent choice for situations that require rapid construction.

One of the most compelling aspects of recycled plastic bricks is their success in developing countries, where they are used in large-scale construction projects. These countries often face challenges in sourcing traditional building materials, and plastic waste is a significant issue. By repurposing plastic waste into bricks, these regions can create affordable housing and other essential infrastructure without relying on the environmental impact of traditional materials like concrete or clay. Several initiatives have successfully implemented this innovation, showcasing its potential to address both waste management and housing shortages in low-income areas.

As a prime example of eco-friendly building materials, plastic bricks are a promising alternative for creating sustainable buildings, while also providing a solution to plastic waste accumulation. Their growing popularity is proof that innovation in construction materials can lead to environmental benefits and improved living conditions in underserved regions.

Autoclaved Aerated Concrete (AAC)

What is it?

Autoclaved Aerated Concrete (AAC) is a lightweight, precast material crafted from a blend of lime, sand, cement, and an expanding agent. The expansion agent reacts with the other ingredients to produce gas bubbles within the mix, resulting in a porous structure that is lighter than traditional concrete. The mixture is then poured into molds, cured under high pressure and temperature in an autoclave (a pressurized steam chamber), and cut into blocks or panels. These blocks are widely used in modern construction for walls, floors, and roofs, offering an alternative for cement-based concrete.

Why it’s sustainable:

AAC is considered a sustainable building material for several reasons. The production process itself is more energy-efficient than traditional concrete manufacturing, which involves high-temperature heating of limestone. AAC’s reduced density means that it requires fewer raw materials, lowering the demand for aggregates and minimizing environmental impact. Furthermore, because it uses less cement, a major contributor to CO₂ emissions, AAC reduces the carbon footprint of construction projects.

Another key benefit of AAC is its energy efficiency. The material’s cellular structure acts as an excellent thermal insulator, which helps buildings retain heat in the winter and stay cooler in the summer. This reduces the energy needed for heating and cooling, leading to lower energy consumption and a reduced carbon footprint over time. This energy efficiency contributes to long-term sustainability in the construction of energy-efficient buildings.

AAC’s exceptional fire resistance enhances both safety and durability, making it an excellent choice for structures in fire-prone regions due to its ability to endure high temperatures without compromising structural integrity.

Applications:

- Walls and partitions: AAC is commonly used for building exterior and interior walls, particularly in large-scale construction projects like residential buildings, schools, and commercial spaces. Its light weight and insulating properties make it a preferred material for both load-bearing and non-load-bearing walls.

- Floors and roofs: In addition to walls, AAC is also used for floor slabs and roof panels, providing a strong and lightweight alternative to traditional concrete.

- Modern construction: Due to its versatility, AAC is employed in a variety of construction applications, including multi-story buildings, where its light weight reduces the load on structural foundations.

One of the most notable benefits of Autoclaved Aerated Concrete is its energy efficiency and fire-resistant properties, which make it ideal for green building projects. Architects and builders are increasingly turning to AAC as a material that not only meets the structural requirements but also contributes to sustainable building practices. In addition to reducing energy use, AAC’s fire-resistant nature can contribute to safer buildings, providing peace of mind to occupants while also reducing the long-term costs associated with maintenance and repairs.

As a lighter concrete alternative, AAC helps reduce transportation costs, as it is easier to handle due to its lower weight. This, in turn, leads to a decrease in the carbon emissions associated with transporting building materials. When considering its excellent energy efficiency, fire resistance, and overall environmental benefits, AAC is an essential material in the growing trend of eco-friendly construction.

Conclusion

In conclusion, the transition to eco-friendly building materials is a vital step toward creating a sustainable future for the construction industry. As awareness grows about the environmental impact of traditional materials such as concrete and steel, there is an increasing demand for alternatives that reduce waste, lower emissions, and minimize resource consumption. The materials discussed, including recycled plastic bricks, autoclaved aerated concrete, bamboo, and mycelium insulation, exemplify the innovative strides being made in sustainable construction practices.

Adopting these eco-friendly materials not only contributes to reducing the carbon footprint of the construction industry but also offers long-term benefits such as energy efficiency, durability, and reduced maintenance costs. As these materials gain wider acceptance and become more accessible, we can expect to see a future where sustainable building becomes the norm, rather than the exception.

It is essential for builders, architects, engineers, and policymakers to continue exploring and embracing sustainable building materials. By fostering innovation and collaborating on the adoption of green technologies, we can reduce the environmental impact of construction and create a more sustainable, healthier built environment for future generations. Let’s explore, innovate, and contribute to a greener planet by integrating these eco-friendly materials into our construction practices.

As we explore various sustainable eco-friendly materials, it’s important to understand other innovations in the construction and sanitation sectors that contribute to a more eco-friendly future.

- Recycled Concrete for a Sustainable Solution: Discover how using recycled concrete can reduce waste, conserve resources, and offer an alternative to traditional concrete. This material exemplifies the ongoing shift towards sustainability in construction.

- Self-Healing Concrete: Learn about the revolutionary self-healing concrete, a material that can repair itself over time, reducing maintenance costs and increasing the longevity of structures.

- Waterless Toilets – Sustainable Sanitation Solution: Explore the concept of waterless toilets as part of sustainable sanitation efforts, offering significant water conservation benefits in areas facing water scarcity.

- Roman Concrete Invention: Delve into the ancient innovation of Roman concrete, a material that has withstood the test of time. Understanding its properties can inspire modern sustainable alternatives in construction.

Each of these topics highlights the growing trend of sustainability in construction and sanitation, making them important considerations as we move toward a greener future.