Introduction

Before the invention of modern agricultural machinery, farmers relied heavily on manual labor to process crops after harvest. Traditional threshing methods, such as using flails or hand-beating stalks of grain, were labor-intensive and time-consuming. These methods required tremendous effort to separate the edible grain (like wheat) from the stalks and husks, often limiting farming productivity.

The invention of the threshing machine during the late 18th century marked a transformative era in agriculture. By automating the threshing process, it not only reduced manual labor but also drastically increased efficiency, paving the way for the mechanized farming revolution of the 19th century. This groundbreaking innovation allowed farmers to produce more food with less effort, contributing to the rapid growth of agricultural economies worldwide.

This blog will explore the history of the threshing machine, how it works, and its lasting impact on modern farming. We’ll also dive into related advancements like the wheat threshing machine and discuss the brilliant minds behind its invention.

What is a Threshing Machine?

A threshing machine is a revolutionary agricultural device designed to automate the process of separating grain, such as wheat or barley, from its stalks and husks. Prior to the invention of the threshing machine, farmers relied on manual methods like flails, where laborers physically beat the harvested crop to extract the grains—a tedious, time-consuming process that limited agricultural productivity.

The Role of the Threshing Machine

The threshing machine emerged as a transformative solution, drastically reducing manual labor and significantly speeding up the threshing process. Instead of hours of intensive work with traditional hand tools, a threshing machine could process large quantities of harvested crops in minutes, liberating farmers from backbreaking labor and enabling faster, larger-scale harvests.

For instance:

- Manual threshing with a flail could take an entire day to process a single acre of wheat.

- With a mechanical threshing machine, the same work could be accomplished in a fraction of the time, often less than an hour.

This shift allowed farmers to increase crop yields and allocate more time to planting, cultivating, and expanding their land for farming.

Traditional Methods vs. Mechanical Threshing

To understand the impact of the threshing machine, it’s essential to compare traditional threshing methods with mechanical alternatives:

| Aspect | Traditional Threshing | Threshing Machine |

|---|---|---|

| Labor | Manual, physically demanding | Minimal manual effort required |

| Time | Extremely time-consuming | Rapid processing of large quantities |

| Efficiency | Low (high grain loss and slow output) | High (reduced loss, higher efficiency) |

| Productivity | Limited to small-scale operations | Enabled large-scale farming |

In traditional methods, grains were often damaged or lost due to inconsistencies in manual threshing. The threshing machine addressed this inefficiency by delivering uniform, clean grain separation, ensuring higher-quality produce with minimal waste.

How a Threshing Machine Works

At its core, a threshing machine operates by feeding harvested crops through a rotating mechanism. This mechanism:

- Feeds the Crop: Bundles of harvested wheat or barley are fed into the machine.

- Separates the Grain: The internal drum, equipped with teeth or beaters, agitates the stalks, loosening the grains from the husks.

- Winnows the Chaff: Through a series of sieves and fans, the machine separates the heavier grains from lighter chaff and debris.

The result is clean, market-ready grain with minimal human intervention.

Who Invented the Threshing Machine?

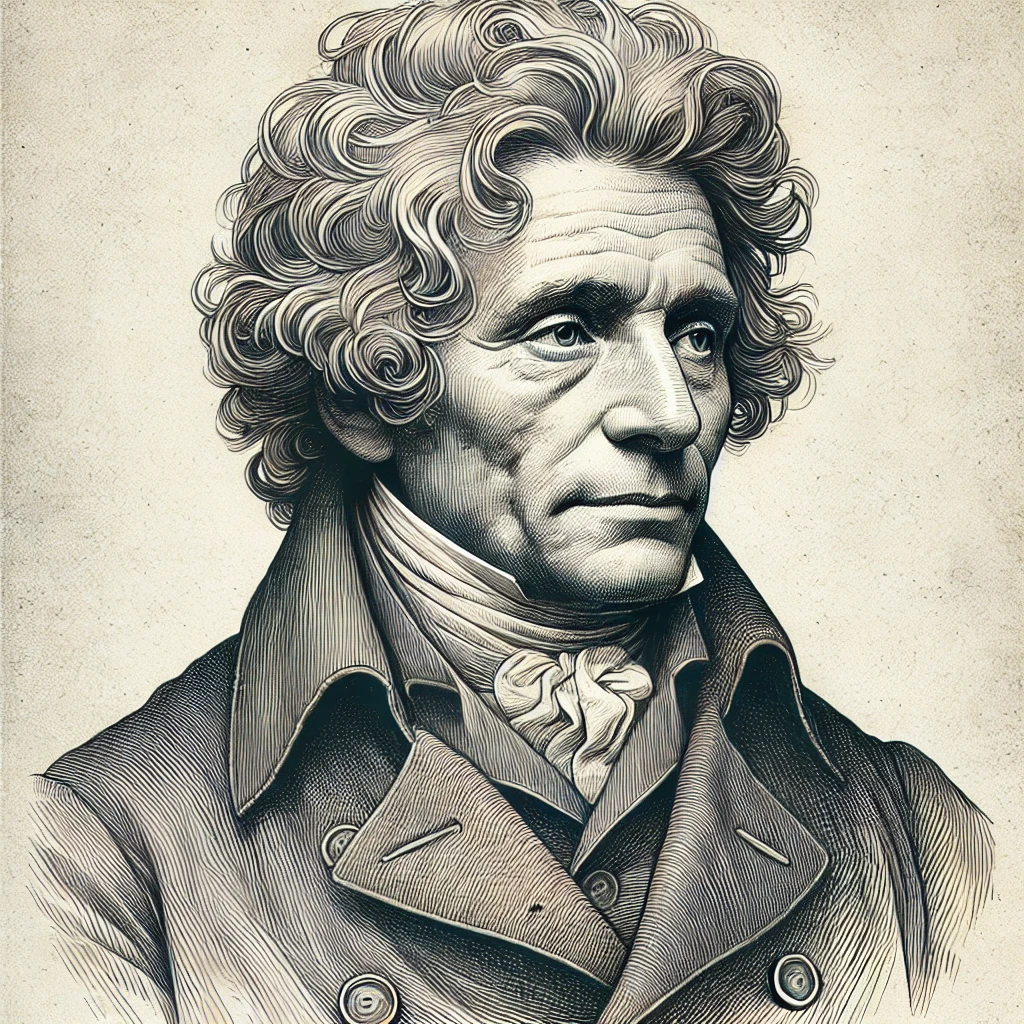

The threshing machine, a revolutionary device in agricultural history, was invented by Andrew Meikle, a Scottish mechanical engineer, in 1786. Meikle’s motivation stemmed from the challenges faced by farmers who relied on manual threshing methods. Traditional techniques, like flailing or hand-beating the harvested grain, were not only physically exhausting but also extremely time-consuming, limiting farmers’ productivity.

Andrew Meikle, observing the struggles of rural farmers, sought to create a mechanical solution. He built upon earlier unsuccessful attempts at automated threshing and developed a more efficient prototype. His threshing machine worked by feeding stalks of grain into a rotating drum, which beat the stalks to separate the grain from the husks—a significant breakthrough in agricultural mechanization.

Joseph Pope, another key contributor in the early 19th century, made adaptations to the machine to suit American farming conditions, improving its efficiency. Across Europe and the United States, regional inventors further refined Meikle’s designs, incorporating locally sourced materials and addressing diverse agricultural needs.

The role of patenting in this period was crucial for spreading the invention. Patents not only protected inventors like Meikle but also fueled industrial innovation by encouraging others to improve upon existing designs. The threshing machine quickly gained traction in the industrial era, sparking widespread adoption and advancing farming practices globally.

History of Threshing Machine

The history of the threshing machine is a fascinating journey through agricultural innovation, shaped by necessity, ingenuity, and technological progress. The invention of the threshing machine revolutionized farming practices, transforming how grain was harvested and significantly improving efficiency.

Early Developments (1700s)

Before the advent of the threshing machine, farmers relied entirely on manual threshing methods to separate grain kernels from stalks and husks. The most common technique, known as flailing, involved beating harvested stalks with wooden tools. This physically exhausting and time-consuming method often limited productivity and strained farm laborers. For large farms, threshing took weeks or even months, delaying the distribution of harvested crops.

In the 18th century, early experiments with primitive threshing mechanisms were conducted in an effort to mechanize this labor-intensive process. However, most of these early prototypes were inefficient and unreliable, failing to gain traction. The need for a practical and effective solution became increasingly urgent as farming expanded across Europe.

Meikle’s Invention (1786)

In 1786, Scottish mechanical engineer Andrew Meikle designed the first successful threshing machine, revolutionizing agriculture. Meikle’s machine utilized rotating beaters to strike the stalks, separating the grain kernels from the chaff and husks. This design was far more efficient than manual methods, dramatically reducing the time and labor required for threshing.

Initially, Meikle’s invention faced resistance. Farmers were skeptical due to the high cost of the machine and the technical skills needed to operate it. Additionally, many farm workers feared that the mechanization of threshing would render their labor obsolete, leading to widespread unrest in some regions. For example, the Captain Swing Riots in England during the early 19th century saw workers protest against the adoption of threshing machines, which they viewed as a threat to their livelihoods.

However, as the benefits of the threshing machine became evident—such as increased productivity, reduced labor demands, and improved efficiency—farmers began to embrace the innovation. The adoption of Meikle’s threshing machine marked the beginning of a new era in agricultural mechanization.

The Industrial Era (1800s)

By the early 19th century, the Industrial Revolution played a critical role in advancing threshing machine technology. Steam engines were introduced and integrated into threshing machines, replacing manual or animal-powered systems. The advent of steam-powered threshing machines allowed farmers to process larger quantities of grain more efficiently, making the machines indispensable for large-scale agriculture in Europe and North America.

The shift to steam-powered machines brought profound changes to rural economies:

- Increased Productivity: Farmers could thresh larger fields in shorter timeframes, leading to greater yields and a steady food supply.

- Displacement of Labor: While mechanization reduced the need for manual labor, it also led to economic and social adjustments as farm workers sought alternative employment opportunities.

Technological Improvements

Throughout the 19th century, threshing machines continued to evolve:

- Early machines with wooden gears were replaced with more durable and reliable iron components, improving performance and lifespan.

- Portability was enhanced, with machines designed to be easily transported between farms.

- The introduction of the combine harvester in the late 1800s marked a significant milestone. Combines integrated threshing, reaping, and winnowing into a single operation, dramatically streamlining the harvesting process. This innovation further increased efficiency and reduced the need for multiple machines.

Modern Innovations

The legacy of the threshing machine lives on in modern agriculture. Today’s threshing machines are highly advanced, fully automated, and powered by diesel or electric engines. Equipped with smart technologies like GPS, sensors, and data analytics, modern threshing machines can:

- Optimize efficiency by adjusting to different crop conditions.

- Minimize grain loss through precision threshing.

- Reduce fuel consumption and environmental impact.

These advancements have cemented the role of the threshing machine as a cornerstone of agricultural mechanization. From Andrew Meikle’s groundbreaking invention in 1786 to today’s cutting-edge equipment, the evolution of threshing machines reflects humanity’s relentless pursuit of innovation to meet the needs of a growing world.

Wheat Threshing Machines and Their Evolution

Wheat threshing, as a specific application of threshing machines, played a critical role in transforming agriculture and global food production.

Why Wheat Threshing Was a Labor-Intensive Process

Before mechanization, threshing wheat was an arduous process requiring significant time and manpower. Farmers relied on manual methods such as flailing—beating wheat stalks with wooden tools—or using animals to tread on the stalks to separate grains. These methods were not only labor-intensive but also inefficient, leading to considerable grain losses. For large-scale wheat farms, manual threshing could take weeks, delaying the availability of food and impacting harvest yields.

Role of Machines in Improving Wheat Yields and Global Food Production

The introduction of wheat threshing machines revolutionized agriculture. By mechanizing the process, farmers could:

- Increase Productivity: Machines drastically reduced the time required to separate wheat kernels from stalks, enabling larger areas to be harvested efficiently.

- Reduce Labor Costs: Fewer workers were needed, allowing farms to scale operations and allocate resources to other critical activities.

- Minimize Grain Loss: Mechanical threshing was more precise, ensuring a higher recovery of wheat kernels compared to manual methods.

As mechanized threshing spread globally, it contributed to increased wheat yields, supporting growing populations and driving food security worldwide.

Key Technological Upgrades

The evolution of wheat threshing machines reflects broader advancements in agricultural technology:

- Mechanical Threshing Machines (1786): Andrew Meikle’s original threshing machine utilized rotating beaters to separate grains from stalks.

- Horse-Drawn Machines (Early 1800s): Machines were adapted to be powered by horse-driven treadmills, increasing their mobility and efficiency on farms.

- Steam-Powered Threshing Machines (Mid-1800s): With the advent of the steam engine, threshing machines became far more powerful and capable of handling large-scale wheat production. These machines were a common sight in regions like the Midwest USA and Europe during the Industrial Revolution.

- Motorized Threshing Machines (Early 20th Century): The development of gasoline and diesel engines allowed threshing machines to become self-powered, reducing reliance on external power sources like horses or steam engines.

- Combine Harvesters (Late 20th Century): Combining harvesting, threshing, and cleaning into a single machine further streamlined wheat farming, dramatically increasing efficiency.

Case Studies: Wheat Farming in Major Agricultural Regions

- Midwest USA: Known as the “breadbasket of the world,” the adoption of steam-powered threshing machines in the 19th century enabled large-scale wheat farming across vast plains. The mechanization of wheat threshing helped the U.S. become a global leader in wheat exports.

- Europe: In countries like the UK, Germany, and Russia, threshing machines revolutionized traditional farming practices, reducing reliance on rural labor during the Industrial Revolution. This led to significant increases in wheat production.

- Asia: In countries such as India and China, traditional threshing methods persisted longer. However, with modern technological advancements, motorized and combine threshing machines have dramatically improved wheat yields, supporting the region’s growing populations.

The evolution of wheat threshing machines highlights their profound impact on global food production, enhancing both efficiency and sustainability in agriculture.

How Threshing Machines Work

Understanding the threshing machine working principle helps clarify how these machines revolutionized agriculture by efficiently separating grain from stalks and husks.

Key Components

- Feeding Mechanism:

- Harvested stalks of grain are fed into the machine using a conveyor belt or manual feeding system. This mechanism ensures a steady flow of material into the threshing chamber.

- Threshing Drum:

- The threshing drum is the heart of the machine. It consists of rotating beaters or spikes that strike the stalks, separating the grains from the husks and straw through impact and friction.

- The drum’s speed and design are critical to prevent grain damage while maximizing separation efficiency.

- Separation Chamber:

- Once the grain is separated, it enters the separation chamber. Here, the heavier kernels fall through sieves or screens, while the lighter straw and chaff are carried away by air flow. This ensures effective separation of the grain from unwanted material.

- Cleaning Systems:

- Modern threshing machines use fans, blowers, or sieves to remove chaff, dust, and small debris. This step ensures that the final output consists of clean, market-ready grain.

Simple Step-by-Step Explanation of the Threshing Process

- Feeding: The harvested crop (e.g., wheat stalks) is fed into the machine’s inlet.

- Threshing: The rotating threshing drum strikes the stalks, loosening the grains from the husks and stems.

- Separation: The grains fall through sieves while the larger straw and husks are ejected from the machine.

- Cleaning: Fans and blowers remove any remaining chaff or debris, leaving clean grain.

- Collection: The cleaned grain is collected and stored for further processing, while straw is expelled for use as fodder or mulch.

Modern Comparison: Integration into Combine Harvesters

Modern threshing machines are now integrated into combine harvesters, which perform three essential tasks in a single operation:

- Reaping: Cutting the standing crop and feeding it into the machine.

- Threshing: Separating grains from stalks using an advanced threshing drum.

- Winnowing/Cleaning: Removing chaff, dust, and straw to deliver clean grains.

Combine harvesters have automated these processes, enabling farmers to harvest vast areas efficiently. Advanced features such as GPS systems, sensors, and real-time monitoring ensure precision and minimal grain loss, making modern machines indispensable in global agriculture.

Impact of the Threshing Machine

The threshing machine was a transformative invention that not only revolutionized agriculture but also brought about significant economic, social, and global changes.

Agricultural Revolution

- Increased Grain Production and Food Security:

The threshing machine drastically improved the efficiency of grain processing, allowing farmers to handle larger harvests in less time. This significantly increased grain yields, contributing to global food security and supporting growing populations. The faster turnaround also enabled multi-season planting in some regions, further boosting productivity. - Reduced Reliance on Manual Labor:

Before mechanization, threshing was one of the most labor-intensive farming tasks. Introducing threshing machines reduced the need for large groups of farm workers, saving time and resources while improving efficiency. Farmers could now manage larger fields with fewer laborers.

The threshing machine became a cornerstone of the Agricultural Revolution, paving the way for modern, large-scale farming practices.

Economic and Social Changes

- Creation of Agricultural Industries:

With the advent of threshing machines, agriculture became increasingly industrialized. The demand for machines led to the growth of manufacturing industries specializing in agricultural tools, creating jobs and boosting economies. Additionally, increased grain production supported the growth of food supply chains, milling industries, and international trade. - Challenges for Rural Laborers (Displacement during Industrialization):

While threshing machines improved efficiency, they also displaced many rural laborers who relied on manual threshing for income. This led to social tensions, particularly during the Industrial Revolution, as rural communities grappled with unemployment and forced migration to urban centers in search of work.

Global Spread

The threshing machine quickly gained widespread adoption across continents:

- Europe: During the Industrial Revolution, mechanization reduced manual labor costs and helped meet the demands of growing urban populations in countries like the UK and Germany.

- North America: The vast wheat fields of the Midwest USA greatly benefited from threshing machines, which were crucial for large-scale farming operations. Steam-powered versions became standard during the 19th century.

- Asia: While traditional methods persisted longer, countries such as India and China eventually adopted threshing machines, improving their agricultural productivity to feed large populations.

The global adoption of threshing machines symbolized a turning point in agriculture, where mechanization became essential for feeding a growing world.

Challenges and Controversies

Despite its revolutionary impact, the threshing machine faced significant challenges and controversies during its early years and even beyond.

Early Skepticism and Resistance to Mechanization

- Many farmers and rural workers were initially skeptical about threshing machines. Their unfamiliarity with mechanical processes led to doubts about the machines’ reliability and effectiveness.

- Organized resistance movements, such as the “Luddites” in early 19th-century England, protested against mechanization. These groups feared that machines would displace workers and threaten traditional livelihoods. Acts of sabotage, including destroying threshing machines, were common during this period.

Quality Concerns: Early Machines Faced Durability Issues

- The first threshing machines were prone to breakdowns due to their mechanical complexity and exposure to harsh field conditions.

- Farmers often faced high repair costs, which limited adoption among smaller landowners who could not afford regular maintenance.

- Improvements in design and materials over time, such as more durable threshing drums and stronger components, eventually overcame these early challenges.

Long-Term Impact on Rural Employment

While threshing machines increased efficiency, they also reduced the need for manual labor. Many rural laborers who relied on seasonal work were displaced, leading to significant socioeconomic changes:

- Migration from rural areas to cities accelerated, as displaced workers sought employment in growing urban industries.

- The gap between large landowners, who could afford machinery, and small farmers, who relied on manual methods, widened.

Although mechanization ultimately improved agricultural productivity, its social impact remains a notable chapter in the history of industrialization.

FAQ

Who invented the first threshing machine and when?

The first mechanical threshing machine was invented around 1786 by Scottish engineer Andrew Meikle. This marked one of the earliest steps in agricultural mechanization, replacing labor-intensive manual threshing.

What exactly does a threshing machine do on a farm?

A threshing machine—or thresher—separates grain seed from stalks and husks. It beats the plant material to dislodge the grain—a process that historically required up to a quarter of agricultural labor.

Why was mechanizing threshing so transformative for agriculture?

Before mechanization, threshing by hand was extremely laborious. The introduction of threshers significantly reduced physical labor, sped up harvest processing, and allowed farmers to cultivate larger areas of land.

What was the Swing Riots and how were they connected to threshing machines?

In the early 19th century, farm laborers revolted—particularly in southeastern England—smashing threshing machines that had replaced manual labor. Known as the Swing Riots, these protests highlighted the social tension caused by mechanization.

How did early threshing machines evolve over time?

Threshing machinery advanced from human- or horse-powered models to steam-powered versions in the 19th century. In the 20th century, they evolved further into modern combine harvesters, which integrate reaping, threshing, and winnowing into one machine.

Are simple threshing machines still used today?

Yes. While combines dominate large-scale farming, simpler threshers remain vital in small-scale or low-capital farming—especially in developing regions. Pedal-powered or hand-operated models still cater to local agricultural needs.

Can threshing machines preserve the straw for reuse?

Absolutely. Unlike combine harvesters that often crush straw, older threshing machines typically keep the straw intact. This preserved straw is valuable for uses like thatching, animal bedding, or other local crafts.

Conclusion

The threshing machine stands as a landmark innovation in agricultural history, fundamentally transforming how farmers process crops and manage food production.

- Historical Significance: By reducing the time and labor required for threshing, these machines enabled a dramatic increase in grain production, paving the way for the Agricultural Revolution. They served as a critical link between traditional farming methods and the modern, mechanized agriculture of today.

- A Precursor to Modern Agricultural Technology: The threshing machine’s principles of mechanical separation and efficiency are still visible in today’s advanced combine harvesters. Modern agricultural machinery builds on these foundations, integrating automation, precision technology, and data-driven farming techniques.

- Closing Thoughts on Technological Progress in Farming:

The story of the threshing machine highlights both the benefits and challenges of technological progress. While it boosted productivity and global food security, it also reshaped societies and economies. As we look to the future, innovations in agriculture will continue to play a vital role in addressing challenges like food demand, sustainability, and labor efficiency.

The threshing machine’s legacy endures as a testament to human ingenuity and the relentless pursuit of progress in farming.

If you enjoyed learning about the history and impact of the threshing machine, you’ll love exploring other revolutionary inventions that transformed agriculture and shaped human progress. Check out the following blogs:

- The Mechanical Reaper: Discover how Cyrus McCormick’s invention revolutionized harvesting and enabled farmers to manage large-scale crops efficiently.

- The Cotton Gin: Learn about Eli Whitney’s groundbreaking invention that transformed the cotton industry by streamlining the separation of seeds from cotton fibers.

- The History of Farming Equipment: A detailed look at the evolution of tools and machines that made farming faster, easier, and more productive.

- The History of Irrigation : Explore how innovative irrigation techniques over centuries have helped civilizations overcome water scarcity and improve agricultural yields.

These blogs dive deeper into the fascinating journey of agricultural innovation and the tools that laid the foundation for modern farming practices.