Introduction: The Unsung Hero of Civilization’s Growth

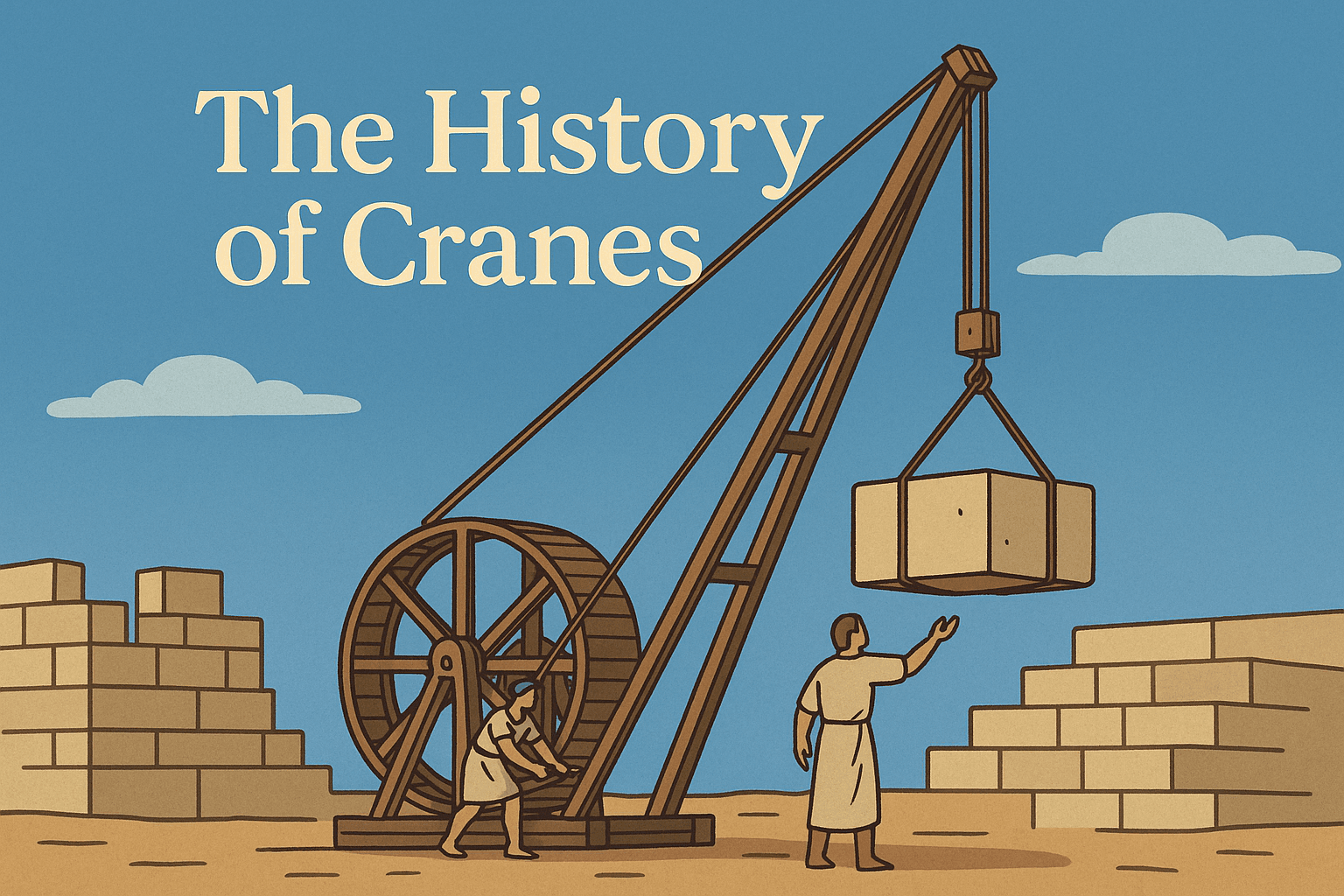

Ever wondered how ancient civilizations lifted stones weighing tons—without diesel engines or electricity?

From the towering pyramids of Egypt to the soaring cathedrals of medieval Europe, humanity has always faced one engineering challenge: how to lift heavy things higher and faster. The solution? A remarkable innovation that dates back more than 2,000 years—the crane machine.

Throughout history, cranes have been the backbone of construction and development, enabling everything from monumental architecture to modern urban skylines. Whether powered by human effort, animal strength, steam, or hydraulics, cranes have evolved into one of the most crucial construction lifting machines in human history.

🏛️ Why the History of Cranes Matters

While today’s tower cranes might look like high-tech marvels, their design principles trace back to ancient Greece and Rome, where early cranes were powered by men walking inside wooden wheels. These machines were so efficient that they could lift stones weighing several tons, setting a new standard for ancient construction.

In short, the history of cranes is the story of how humans overcame gravity—and scaled new heights, literally and figuratively.

🔍 What This Blog Will Cover:

- A journey through the history of cranes, from ancient ingenuity to industrial innovation

- Key milestones in crane evolution and their cultural impact

- A breakdown of the 12 main types of modern cranes and how they work

- How cranes continue to shape the future of construction, logistics, and heavy industry

🏛️ The Birth of the Crane: Ancient Greek Innovation

When we trace the history of cranes back to its origins, we land in ancient Greece, around the 6th century BCE. It was here that humans first devised a mechanical system to lift and place massive stone blocks, revolutionizing construction in a way that echoes through today’s skylines.

🏗️ The ancient crane machine wasn’t powered by motors or hydraulics—it was powered by human ingenuity, pulleys, and raw muscle.

🏺 How the Ancient Greeks Invented the First Crane

The earliest ancient crane machines emerged during the Archaic period of Greece, when stone temples began replacing wooden structures. Builders needed a reliable way to lift multi-ton stone blocks several meters high—especially as temple columns and walls grew in scale and complexity.

Greek engineers responded with an elegant solution:

- Pulleys were attached to lifting beams made of wood

- Ropes and tethers, often made from twisted animal hide or natural fibers, were fed through the pulleys

- Manual winches or treadwheels, operated by men walking inside giant wheels, provided the torque to lift heavy weights

This was mechanical advantage at its finest. By redistributing weight and force, a small group of workers could raise several-ton blocks—with surprising precision.

🧱 Archaeological Clues: Evidence in Stone

Evidence of these early crane systems isn’t just theoretical—it’s carved in stone. Literally.

Archaeologists have discovered:

- Lifting sockets and iron clamps on ancient Greek blocks

- Grooves and inscriptions indicating crane usage

- Stone marks suggesting that blocks were lifted vertically, not dragged or rolled

For example, at the Temple of Apollo at Corinth, multiple stone blocks show consistent bore holes that match the known placement of crane hooks or lifting tongs.

🔁 From Manual to Monumental

The invention of the crane allowed ancient builders to move beyond flat structures. The construction of towering temples, multi-tiered theaters, and fortified city walls wasn’t solely a triumph of design—it was made possible through the ingenuity of mechanical engineering.

This innovation set the foundation for every construction lifting machine that followed, from Roman treadwheel cranes to modern tower cranes.

🏗️ Cranes in the Roman Empire & Middle Ages

After inheriting and adapting early lifting technologies from the Greeks, the Romans took crane design to a new level—scaling it up for imperial ambition. With larger cities, monumental infrastructure, and an expanding empire, the Romans needed stronger, more efficient crane systems to meet the demands of their massive construction projects.

🏛️ Roman Refinement: The Rise of the Treadwheel Crane

One of Rome’s most important innovations in Roman construction equipment was the treadwheel crane—a powerful evolution of the manual winch. This version featured:

- A large wooden wheel, often 4 to 6 meters in diameter

- Operators walking inside the wheel like hamsters to power the lift

- A pulley system that dramatically increased lifting capacity, allowing loads up to 6,000 kilograms (13,000+ lbs)

These Roman cranes were essential for lifting heavy stones used in:

- Aqueduct construction, such as the Pont du Gard in France

- Harbor infrastructure, for loading cargo and lifting columns

- Amphitheaters and temples, including the Colosseum, which used cranes to raise massive stone blocks

📌 Fun fact: Roman engineers used multiple cranes in tandem to lift obelisks and entire arches into place—setting engineering benchmarks not rivaled for centuries.

🏰 Transitioning into the Middle Ages: Cranes for Cathedrals and Ships

As the Roman Empire fell and Europe entered the Middle Ages, crane technology didn’t vanish—it evolved.

⚒️ Medieval Cranes were adapted for:

- Cathedral construction, such as Notre-Dame and Cologne Cathedral, where treadwheel cranes were hoisted on scaffolding to lift stones and timber

- Shipbuilding, especially in places like Venice and Hamburg, where cranes loaded masts, cannons, and sails onto vessels

- Water-powered port cranes, particularly in northern Europe (e.g., Bruges, Ghent), where waterwheels were harnessed to drive mechanical lifting systems

These medieval cranes were often mounted on rotating wooden towers, enabling them to pivot loads with greater control—a significant advancement in lifting precision.

🛠️ The word “crane” itself comes from the bird—with its long neck and strong lifting ability—mirroring the mechanical arms used in early lifting machines.

🔗 From Empire to Innovation

Both Roman and medieval cranes laid the mechanical groundwork for the construction lifting machines we see today. From churches to ships, from stone to steel, cranes remained the silent force behind every great building feat across centuries.

🔩 Industrial Revolution: The Age of Steam and Steel

The evolution of crane technology took a giant leap forward during the Industrial Revolution. From the late 18th to the 19th century, the world saw the transition from wood and rope to cast iron, steel, and steam-powered machinery—ushering in the era of the industrial crane machine.

This was more than a technological upgrade—it was a total transformation of how the world built, moved, and expanded.

🚂 Steam-Powered Cranes Change Everything

Steam engines marked the first time in history that machines took over the heavy lifting once done by human and animal power. These new cranes could:

- Lift 10 to 50 times more weight than manual or treadwheel cranes

- Operate continuously without fatigue

- Be installed on rail tracks, barges, and construction yards for mobile lifting operations

🔧 Steam allowed crane machines to lift locomotives, steel beams, and massive cargo loads—something unimaginable just a century earlier.

🏭 Where Industrial Cranes Were Used

Steam-powered and later hydraulically-assisted cranes became essential in major infrastructure projects during the Industrial Era:

⛏️ Mining

- Cranes helped lift iron ore, coal carts, and machinery deep in and out of mineshafts

- Made it possible to build deep mining tunnels and operate robust industrial hoists.

🚉 Railways

- Used to position iron rails, load freight, and assemble bridge components

- Crane locomotives—mobile crane machines mounted on rails—were invented to service the expanding railway networks

🌉 Bridge and Steelwork Construction

- Enabled the assembly of iconic bridges like the Clifton Suspension Bridge in England and the Eiffel Tower’s iron framework

- Steel cranes became a backbone of early skyscraper construction

🏗️ From Manual Muscle to Mechanical Might

The industrial crane machine marked a major shift in the evolution of crane technology. It was no longer about adapting ancient tools—it was about building entirely new machines, powered by steam and steel, to match the demands of an industrializing world.

This period also introduced gear-driven hoists, hydraulic pistons, and counterweight balancing systems, many of which are still used in modern crane designs.

⚙️ Hydraulic and Electric Cranes: Transforming Lifting in the 20th Century

As the 20th century dawned, the crane machine entered a new phase of evolution—one defined by precision, power, and portability. The advent of hydraulic lifts, electric motors, and advanced counterbalance mechanisms transformed cranes into more intelligent, safer, and highly mobile machines.

This century marked the shift from stationary giants to versatile, road-ready machines that could lift heavier loads with greater control than ever before.

🛠️ Key Innovations That Changed the Crane Game

💧 Hydraulic Lifting Systems

Hydraulics use fluid pressure to transmit force, offering smooth and powerful lifting. These systems revolutionized cranes by:

- Allowing compact but high-capacity lifting arms

- Making it easier to extend, retract, and rotate booms

- Reducing manual labor and increasing operator safety

⚡ Electric Motors

Replacing steam and manual gears, electric motors provided:

- Instant torque for lifting without delay

- Finer control over load positioning

- Energy efficiency and quieter operation, ideal for urban areas

⚖️ Counterbalance Engineering

As cranes grew taller and stronger, preventing tipping became critical. The integration of:

- Rear counterweights

- Load moment indicators (LMIs)

- Stability sensors

made cranes more stable and far safer on all terrains.

📈 Crane Machine Evolution Timeline (20th Century Highlights)

| Era | Key Crane Innovations |

|---|---|

| Early 1900s | Introduction of fixed electric dock cranes at ports for loading ships efficiently |

| 1940s–1950s | Emergence of truck-mounted cranes, combining highway mobility with job-site lifting |

| 1960s–1970s | Rise of crawler cranes, with continuous tracks for rough terrain and heavy-duty lifting |

| 1980s onward | Hydraulic and telescopic cranes dominate urban and industrial construction |

🚛 From Stationary to Mobile Marvels

This century marked a major turning point: the crane machine no longer had to stay in one place. Construction crews could now bring high-lifting capability directly to the job site—from skyscrapers in New York to wind farms in remote landscapes.

Hydraulic lifting systems made cranes:

- Compact enough to fit on trucks

- Flexible enough for city environments

- Strong enough for industrial megastructures

Today’s cranes combine these legacy systems with digital interfaces, GPS stabilization, and load-monitoring AI—but the 20th century laid the foundation.

🏗️ The 12 Types of Cranes Used Today (With Real-World Uses)

Modern construction, shipping, and infrastructure projects rely on a variety of cranes, each engineered for specific tasks. Understanding the 12 types of cranes and their real-world applications offers insight into how today’s heavy lifting machines are tailored to solve complex logistical challenges across industries.

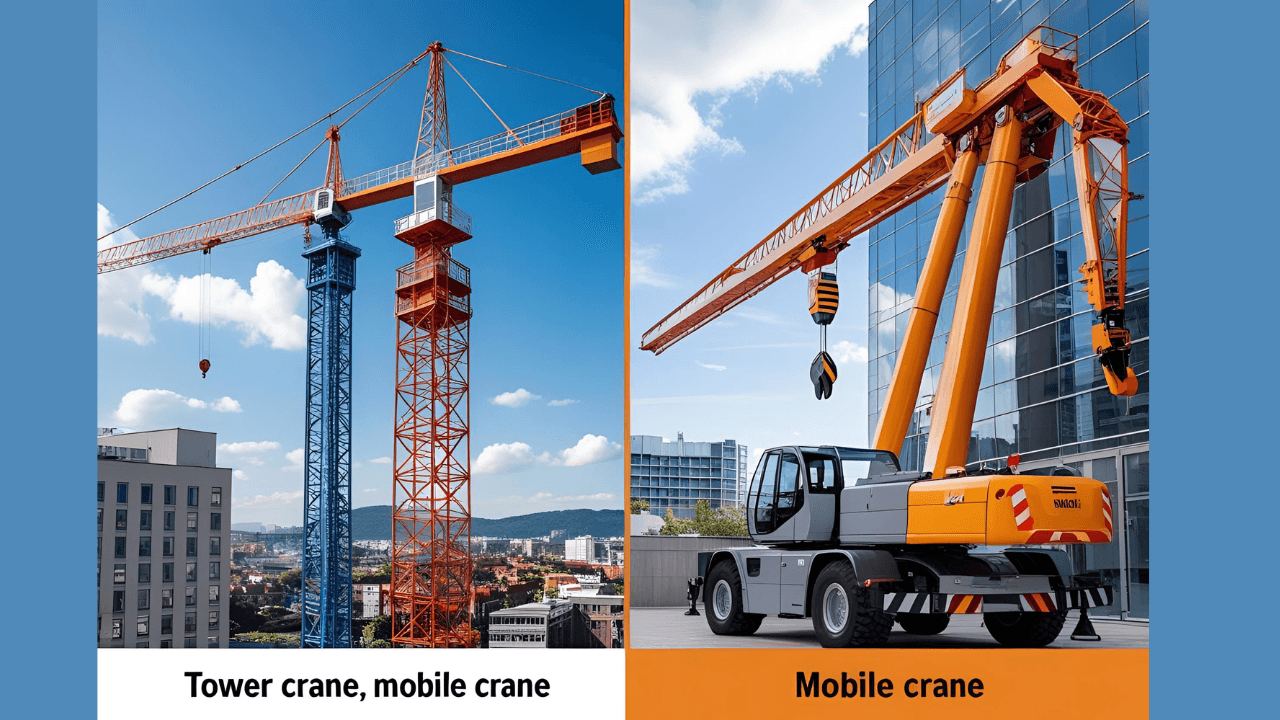

Tower Crane – The Backbone of Skyscraper Construction

- Use Case: High-rise buildings, bridges, and mega-projects

- Details: Tower cranes are fixed to the ground or to building cores during construction. They feature a vertical mast, slewing jib, and counterweights for balance. Their long horizontal jib allows materials to be lifted and moved across large areas.

- Capacity: Typically up to 20 tons, with heights over 250 feet (can be increased with anchoring).

- Example: Used in constructing the Shard (London) and Burj Khalifa (Dubai).

- Why It Matters: These cranes are irreplaceable in dense urban environments where vertical building is essential.

Mobile Crane – The All-Purpose Lifter

- Use Case: Urban construction, temporary jobs, rescue operations

- Details: Mobile cranes are mounted on trucks or wheeled platforms and equipped with either a telescopic or fixed boom. Their ability to travel directly to job sites minimizes setup time and lowers operational costs.

- Capacity: Ranges from 10 tons to over 100 tons, depending on the crane’s design and specifications.

- Flexibility: Can be set up quickly and operated in tight urban spaces

- Why It Matters: Their speed and portability make them the go-to solution for small to mid-sized projects or emergency lifting.

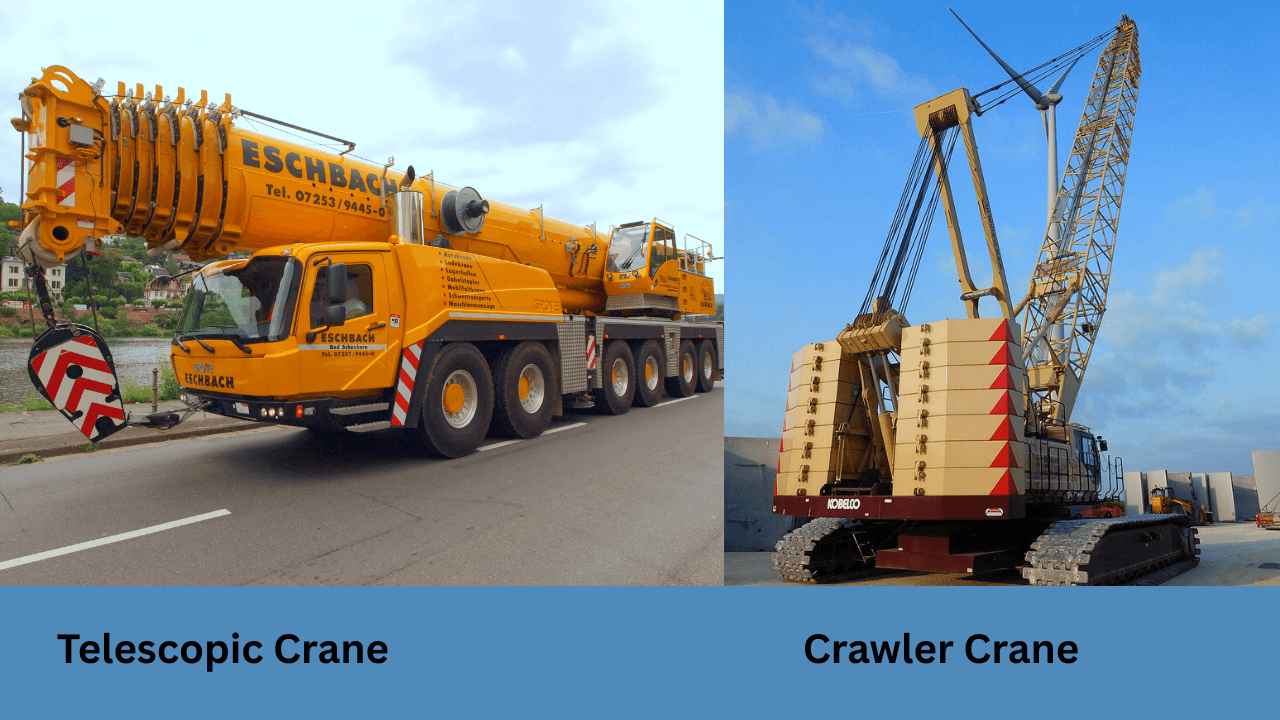

Crawler Crane – Heavy-Duty on Tracks

- Use Case: Power plants, bridges, wind farms, industrial projects

- Details: Crawler cranes are track-based cranes that don’t require outriggers. Their strong lifting capacity and solid stability make them perfect for challenging terrain and extended construction tasks.

- Capacity: Up to 3,500 tons (some of the largest in the world)

- Mobility: Slow-moving but capable of traveling with heavy loads across job sites

- Why It Matters: Crawler cranes are ideal when the ground is soft and heavy lifts are required in difficult environments.

Telescopic Crane – Reach That Adapts

- Use Case: Building repair, emergency rescue, small construction sites

- Details: These cranes are equipped with a boom composed of nested tubes that extend and retract using hydraulic power.

- Boom Length: Ranges from 10m to over 100m, depending on crane class

- Compactness: Often mounted on a mobile base, making them quick to deploy

- Why It Matters: Perfect for jobs requiring variable reach, such as reaching over buildings or into confined spaces.

Truck-Mounted Crane – Road-Ready Lifting

- Use Case: Utility pole installation, mobile construction jobs, short-term lifting

- Details: Combines the functionality of a transport vehicle and a crane, with a rotating superstructure mounted to a truck chassis.

- Speed: Can reach job sites via public roads, avoiding the need for flatbeds or escorts

- Load Capacity: Usually from 10 to 60 tons

- Why It Matters: Ideal for on-demand lifting, particularly where mobility is critical.

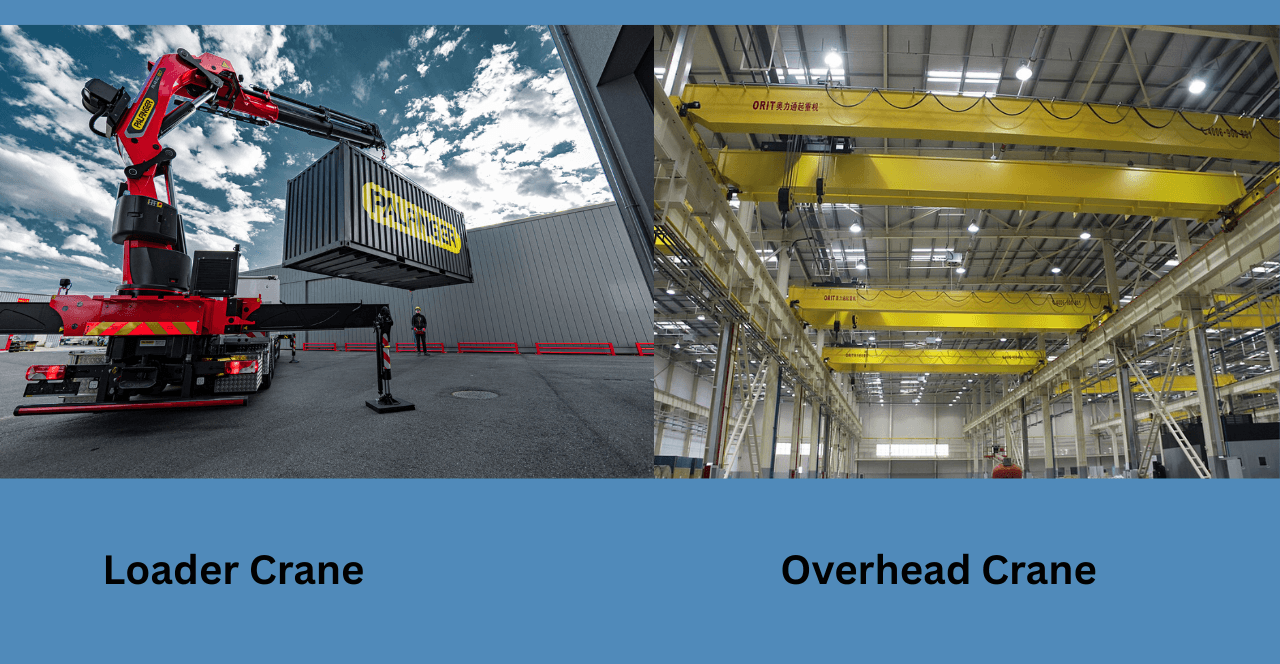

Overhead Crane – Indoor Industry Powerhouse

- Use Case: Manufacturing plants, assembly lines, foundries

- Details: Also called bridge cranes, these systems consist of a crane bridge running along elevated tracks, with a trolley and hoist to move loads in multiple directions.

- Customizable: Designed for specific building sizes and lift tasks

- Capacity: Ranges from 1 to 500 tons+, depending on industry

- Why It Matters: Provides precise, efficient lifting inside large industrial facilities without needing floor space.

Loader Crane – The Compact Helper on Trucks

- Use Case: Delivery operations, pipe laying, pallet loading

- Details: Also called knuckle boom cranes, loader cranes are mounted to trucks and can fold away when not in use.

- Design: Uses articulated arms and hydraulic cylinders for folding movement

- Reach & Strength: Moderate lifting capacity, optimized for short-range, frequent loads

- Why It Matters: They maximize payload efficiency for trucks, making logistics smoother for transport companies.

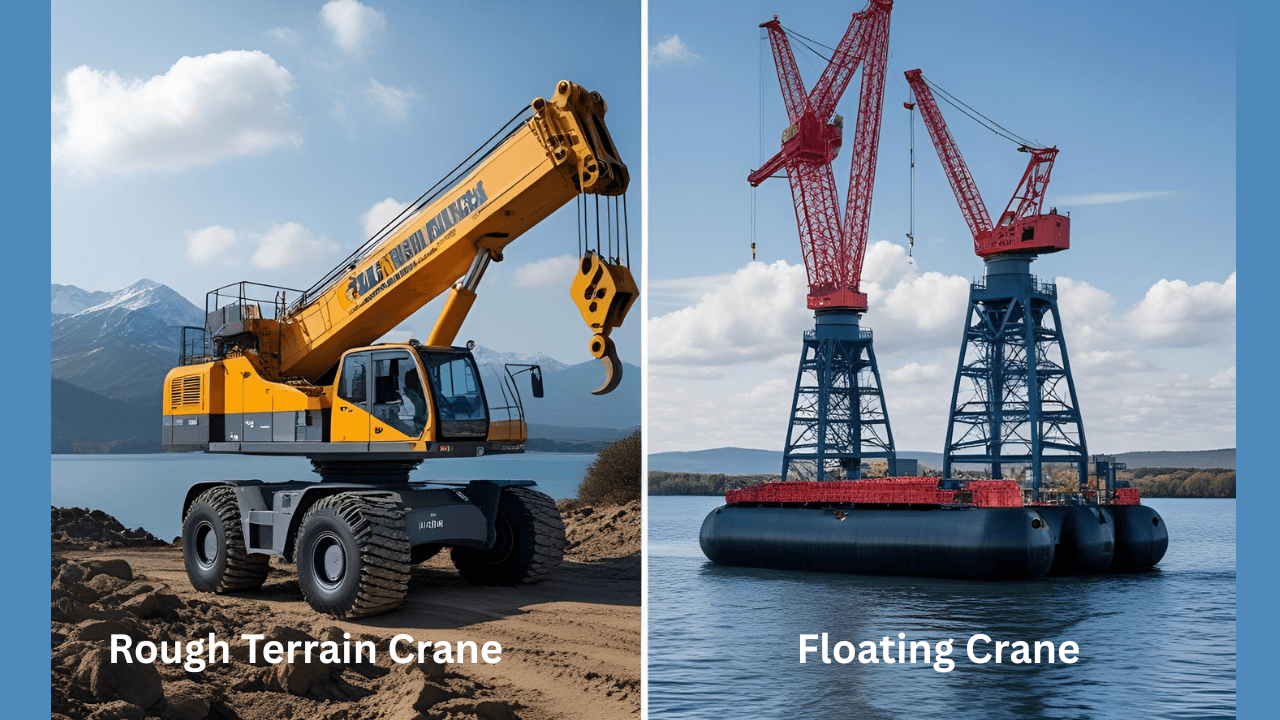

Rough Terrain Crane – Built for the Toughest Conditions

- Use Case: Remote construction, pipeline laying, energy sector

- Details: Equipped with oversized tires, four-wheel drive, and high ground clearance, these cranes are designed to operate on rocky, uneven, or muddy ground.

- Setup: Often has hydraulic outriggers for added stability

- Capacity: Between 30 and 150 tons

- Why It Matters: Essential for off-road environments, especially where paved roads are unavailable.

Floating Crane – Lifting on Water

- Use Case: Shipbuilding, offshore drilling, underwater construction

- Details: Mounted on barges or ships, floating cranes lift heavy equipment and materials over water bodies, harbors, and docks.

- Capacity: Some models exceed 10,000 tons, making them ideal for mega maritime projects

- Why It Matters: Enables construction and cargo handling in marine and offshore zones where land-based cranes can’t reach.

Bridge Crane – Precision for Industrial Automation

- Use Case: High-volume manufacturing, automation lines

- Details: These overhead cranes operate on fixed rails and are integrated into factory automation systems. They often use PLC controls or remote operation.

- Common in: Warehousing, car manufacturing, metal fabrication

- Why It Matters: Crucial for precision material handling in high-speed, repetitive industrial tasks.

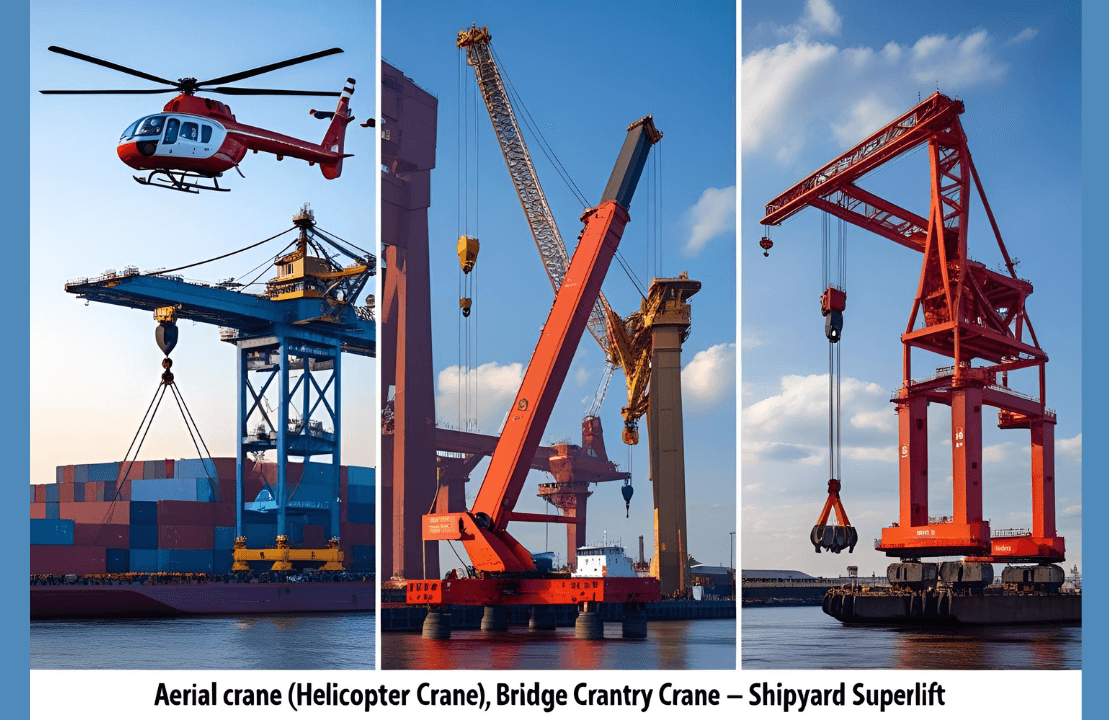

Aerial Crane (Helicopter Crane) – Lifting Where Roads Don’t Go

- Use Case: Remote telecom towers, forest infrastructure, disaster relief

- Details: Aerial cranes, typically operated by helicopters, are used to transport heavy loads to locations that are inaccessible to ground-based cranes, such as mountaintops, forests, or disaster zones.

- Payload: Can lift up to 15,000 pounds, depending on aircraft

- Why It Matters: Often the only option for lifting in mountainous, flooded, or war-torn areas.

Gantry Crane – Shipyard Superlift

- Use Case: Shipyards, steel mills, container ports

- Details: A gantry crane runs on ground-mounted rails with a bridge and hoist suspended between vertical supports. In contrast to overhead cranes, gantry cranes are freestanding and easily scalable to accommodate larger loads or workspaces.

- Capacity: Can lift hundreds of tons of cargo or shipping containers

- Why It Matters: Indispensable for loading/unloading ships, building submarines, or moving oversized components in industrial yards.

🚀 How Cranes Are Built for the Future

As construction demands grow more complex, so do the machines that build them. The future of crane technology is being shaped by automation, sustainability, and intelligent systems—creating smart cranes that are safer, faster, and more efficient than anything that came before.

🤖 Emerging Innovations in Crane Design

📡 Remote-Controlled Cranes

Modern cranes are increasingly operated remotely via joystick or touchscreen, allowing operators to:

- Maintain a safe distance from hazardous zones

- Gain better visibility through mounted cameras and sensors

- Reduce fatigue with ergonomic control stations

Example: Liebherr’s LTM 1110-5.2 offers remote lift control and even semi-autonomous positioning.

🧠 AI for Load Balancing and Efficiency

Artificial Intelligence in construction is no longer theoretical. AI systems now:

- Monitor real-time loads and adjust tension and balance automatically

- Predict wind impacts, sway, and movement using machine learning algorithms

- Integrate with BIM (Building Information Modeling) for seamless coordination with site operations

Example: Manitowoc’s Crane Control System (CCS) integrates real-time sensors and AI-based algorithms to enhance load stability and automatically adjust lift paths for safer, more efficient operations.

🌱 Eco-Friendly Hydraulic and Electric Systems

Sustainability is driving innovation in crane design:

- Electric-powered cranes reduce carbon emissions and noise on urban sites

- Bio-hydraulic fluids and regenerative energy systems are replacing conventional oil-based hydraulics

- Hybrid cranes use dual power sources for flexible, cleaner operation

Example: Tadano’s “E-Pack” electric crane module allows full crane operation with zero emissions in noise-sensitive or indoor environments.

📊 The future of cranes isn’t just about lifting heavier—it’s about lifting smarter, greener, and with greater safety and precision than ever before.

FAQ

When and where were the first cranes invented?

The earliest cranes date back to around the 6th century BCE in ancient Greece. They were primarily wooden structures powered by human or animal labor. Archaeological evidence from stone blocks with lifting holes suggests that these primitive cranes were used in temple construction.

How did ancient civilizations use cranes in construction?

In Greece and Rome, cranes were mainly employed to lift heavy stones for temples, aqueducts, and monumental buildings. The Romans advanced crane technology with treadwheel cranes, which allowed multiple workers to lift much heavier loads than before.

What role did cranes play in the Middle Ages?

During the medieval period, cranes were crucial in building castles, cathedrals, and harbors. Large harbor cranes, often fixed to stone towers, helped load and unload ships. These cranes relied on treadwheels or windlasses powered by human strength.

When did cranes transition from wooden to metal construction?

The Industrial Revolution (18th–19th century) marked the shift. Iron and steel replaced wood, making cranes stronger and capable of lifting significantly heavier loads. Steam engines were also introduced, eliminating the need for purely manual labor.

How did steam and hydraulic power change crane history?

Steam-powered cranes in the 19th century revolutionized construction and shipping, especially in ports and railway yards. Later, hydraulic systems allowed smoother, more precise movements, leading to safer and more versatile lifting operations.

What was the impact of mobile and tower cranes in the 20th century?

Mobile cranes on trucks increased flexibility, allowing lifting operations anywhere roads could reach. Tower cranes, developed in the early 20th century, transformed skyscraper construction by enabling builders to lift steel beams and concrete to great heights.

How are modern cranes powered and controlled?

Today’s cranes typically use diesel engines, electric motors, or hybrid systems. They are equipped with computerized controls, sensors, and safety systems that enhance precision, reduce accidents, and allow remote operation.

What does the future hold for crane technology?

The future of cranes includes automation, AI-powered control systems, and integration with digital construction tools like Building Information Modeling (BIM). Some prototypes also explore drone-assisted lifting and eco-friendly electric cranes to reduce carbon emissions.

🏛️ Conclusion: The Machine That Built Civilizations

From the wooden pulley systems of ancient Greece to today’s AI-powered mega-machines, cranes have stood at the center of human progress. They’ve lifted not only stones and steel—but the visions of empires, architects, and engineers across millennia.

As we’ve explored in this blog:

- The evolution of cranes showcases remarkable ingenuity, progressing from simple hand-powered winches to today’s massive, hydraulically driven machines.

- Each era saw its own evolution—from Roman treadwheel cranes to tower cranes shaping the skylines of Dubai and Shanghai

- And now, with smart systems and sustainability in focus, we are witnessing a new chapter in the evolution of crane technology

🏗️ From temples to towers, the crane’s evolution is the story of human ambition—lifted one ton at a time.

So the next time you see a crane silhouetted against the sky, remember: it’s not just lifting steel beams—it’s lifting civilization itself.

👉 Interested in how other farming and industrial tools shaped human progress? Don’t miss these deep dives into agricultural innovation:

- The History of Farming Equipments

- The Threshing Machine – History, Function, and Impact

- Cotton Gin Invention

- Mechanical Reaper Farming Tool

Explore how these machines revolutionized labor, productivity, and society—just like cranes did in construction.